Method for operating a clutch of a hybrid powertrain and powertrain

A hybrid power and clutch technology, applied to clutches, mechanical equipment, etc., can solve the problem that the intersection point no longer appears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

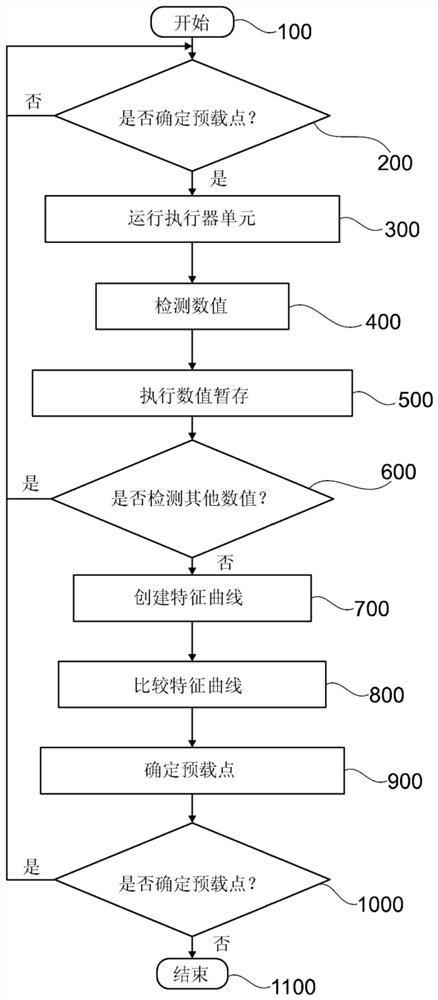

[0026] exist figure 1 The method according to the invention according to a preferred first embodiment is schematically shown in . The shown flow chart is implemented in particular by software with the aid of logic for actuating the operating device 3 . exist Figure 4 The actuating device 3 shown schematically in FIG. 1 is in turn used to actuate the clutch 1 in the drive train 2 of the motor vehicle. The drive train 2 is designed as a hybrid drive train, so that, in addition to the internal combustion engine 5 , it also has an electric machine 4 / electric motor. The clutch 1 is inserted in the drive train 2 between the internal combustion engine 5 and the electric machine 4 in the form of a disconnect clutch, ie in the form of a friction clutch / friction lining clutch. The electric machine 4 is an electric traction drive. Connected to the electric motor or electric traction drive, the transmission 9 is included in the drive train 2 . The actuating device 3 , which acts on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com