Prestress concrete-steel hybrid tower frame for wind generating set

A technology for wind turbines and concrete, which is applied in wind power generation, configuration of installation/support of wind turbines, sustainable manufacturing/processing, etc. The problems of inconvenient storage and transportation of curved tower pieces can achieve the effect of high rigidity, simplified design and manufacture, and high damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A kind of prestressed concrete-steel mixed tower frame of this embodiment is made up of upper steel tower frame 3, lower concrete tower frame 2 and prestressed tendon 4, as figure 1 shown.

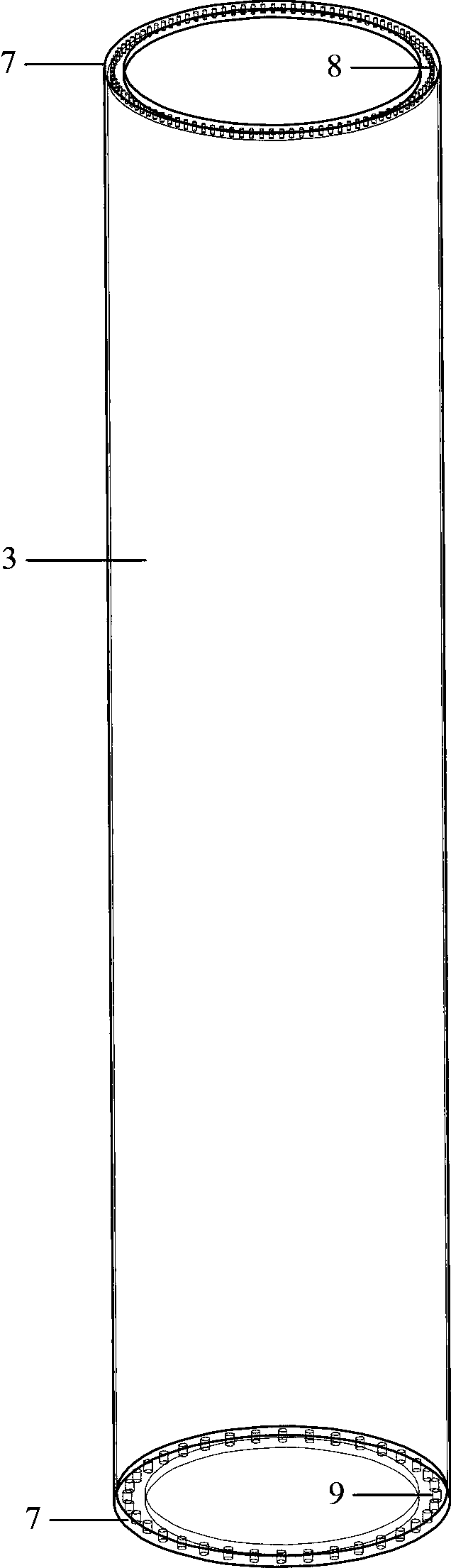

[0027] The upper steel tower 3 is formed by connecting one or more conventional steel towers through flange bolts. figure 2 It is a schematic diagram of a single-section steel tower, the body of which can be in the form of a cylinder or a cone, and L-shaped or T-shaped flanges 7 are welded at both ends of the tower.

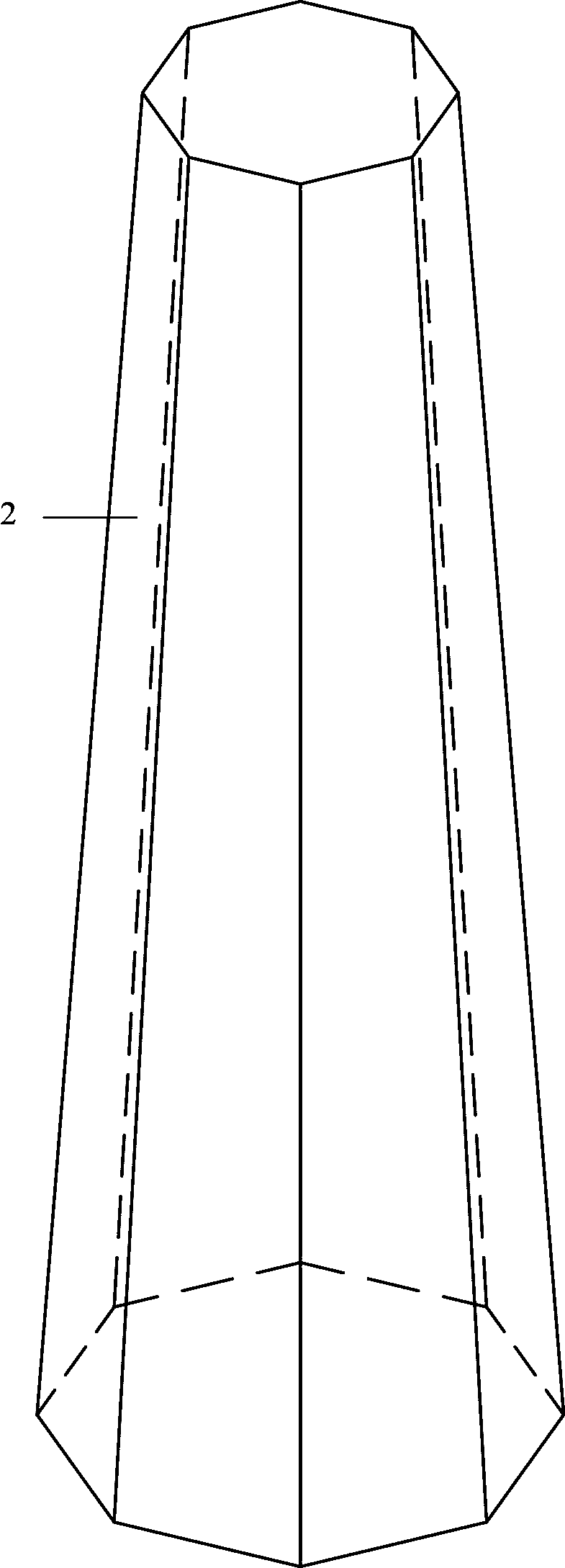

[0028] The lower concrete tower frame 2 is composed of multi-section polygonal concrete tower sections stacked up and down sequentially, and the adjacent two sections can be connected by dry connection methods such as bolts or wet connection methods such as grouting. There are a certain number of installation and positioning holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com