A suction-extruded semi-membrane ignition module capable of single or multiple ignitions and its working method and igniter filling method

An ignition module and multiple ignition technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the deviation of the filling volume of the ignition pipeline, cannot achieve multiple filling of the ignition agent, and affect the stability of the ignition process. and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

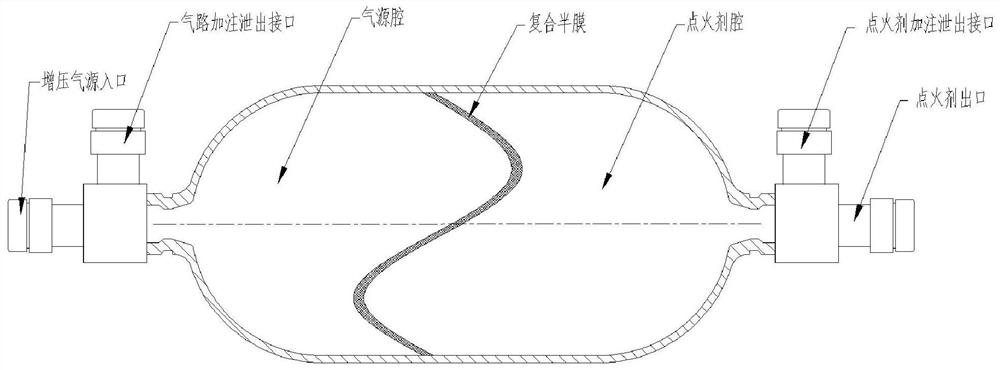

[0043] The present invention is a working method and an ignition agent filling method of a semi-membrane type ignition module that can be ignited once / multiple times by suction and extrusion. The semi-membrane is used to isolate the gas source and the ignition agent of the storage tank, and the pressure difference between the two ends of the half-membrane is adjusted. By changing the ratio of the gas source and the volume of the igniter chamber, the effective volume of vacuuming and nitrogen replacement can be precisely controlled; the half-membrane pressure difference can be adjusted to change the volume of the igniter chamber, forming a negative pressure suction to fill the igniter, realizing a single Accurate and quantitative control of filling interface ignition agent filling, ignition agent injection speed and injection volume; through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com