Apparatus and process for filling containers of different sizes and shapes

A filling material, powdered technology, applied in the field of finely divided solid materials, can solve the problems of low filling capacity, high equipment cost, no economy, etc., and achieve the effect of high bulk weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

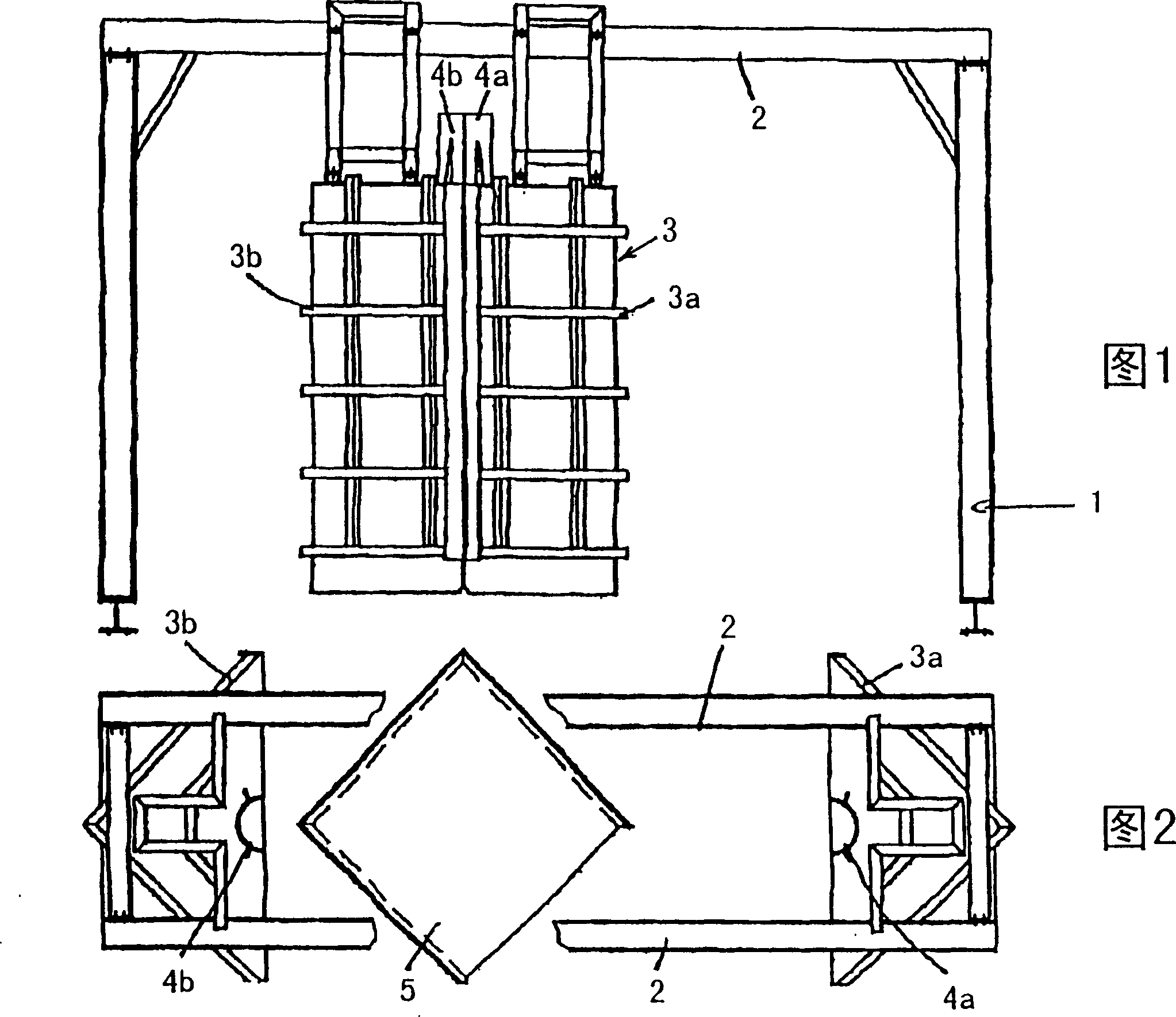

[0047] As shown, the preferred embodiment of the invention comprises a frame 1 provided at the top with two rails 2 along which the two halves 3a and 3b of the housing 3 can be moved by conventional drive means .

[0048] In the embodiment shown in FIGS. 1 and 2 , the casing has a square base area and is divided diagonally into the two halves 3 a and 3 b. This ensures that the two halves are easily separated from the filled container, even if the container is squeezed against the casing due to high filling pressures.

[0049] The casing also has two sleeve halves 4a and 4b which, when closed, surround a feed nozzle (not shown).

[0050] As shown in FIG. 2, the casing 3 is open at the bottom and the container rests on a bracket or pallet 5 during the filling process. Furthermore, it is an advantageous configuration, as shown in the figure, that the filling nozzles are arranged symmetrically with respect to the frame 1, so that the housing halves 3a can be moved further away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com