Multicomponent cartridge with venting apparatus

A multi-component, ventilation element technology for use in exhaust devices, containers with multiple items, devices for applying liquids to surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

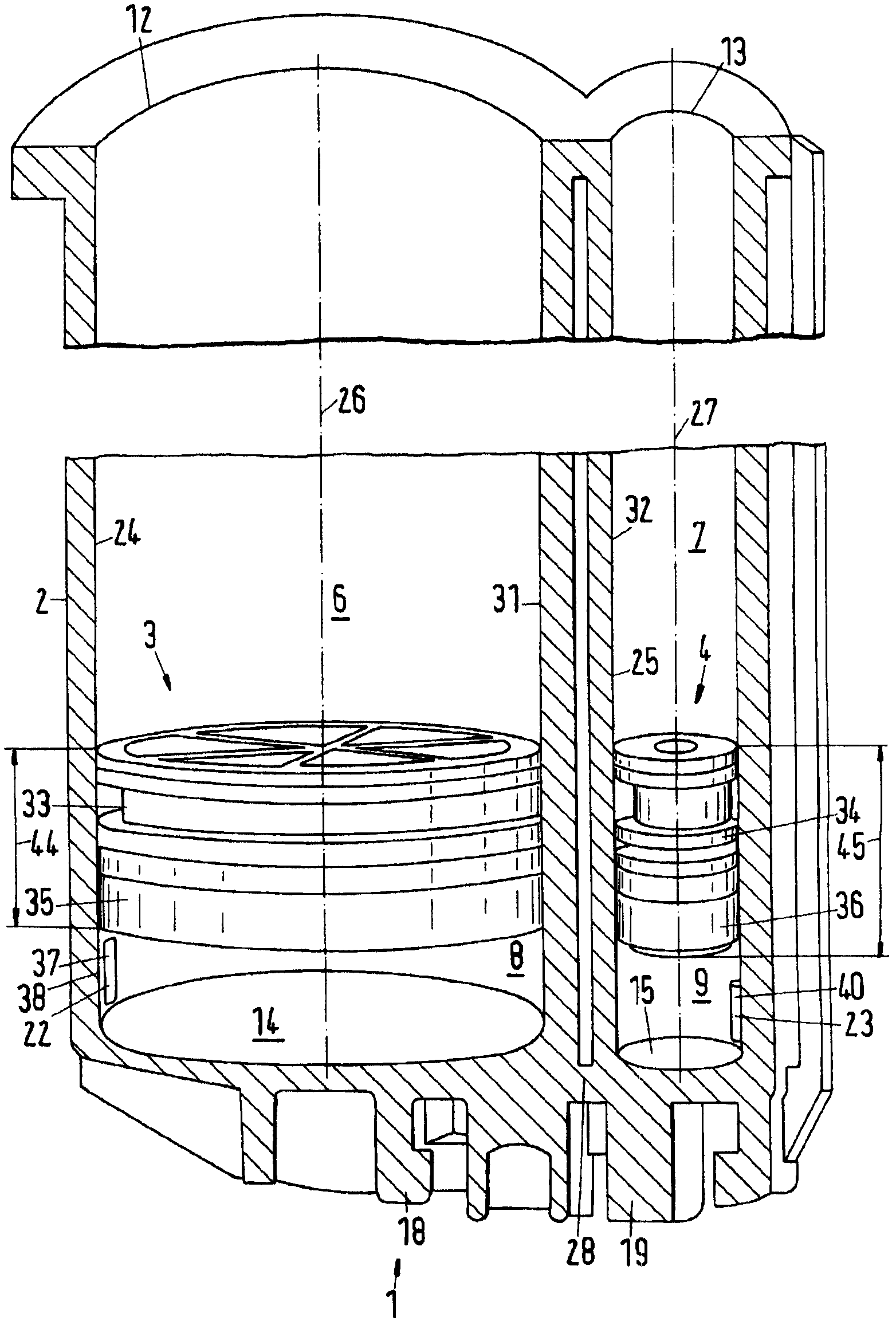

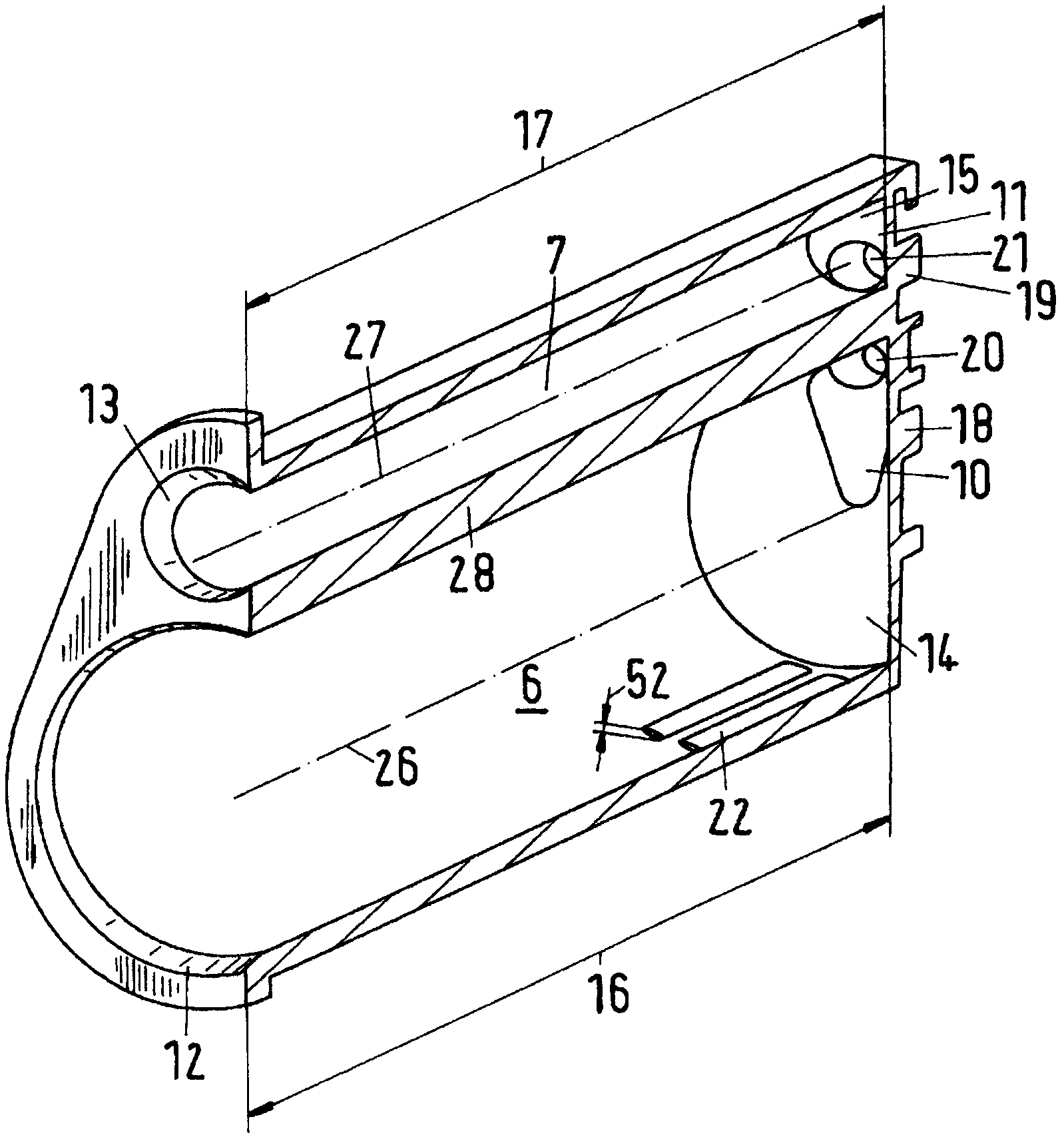

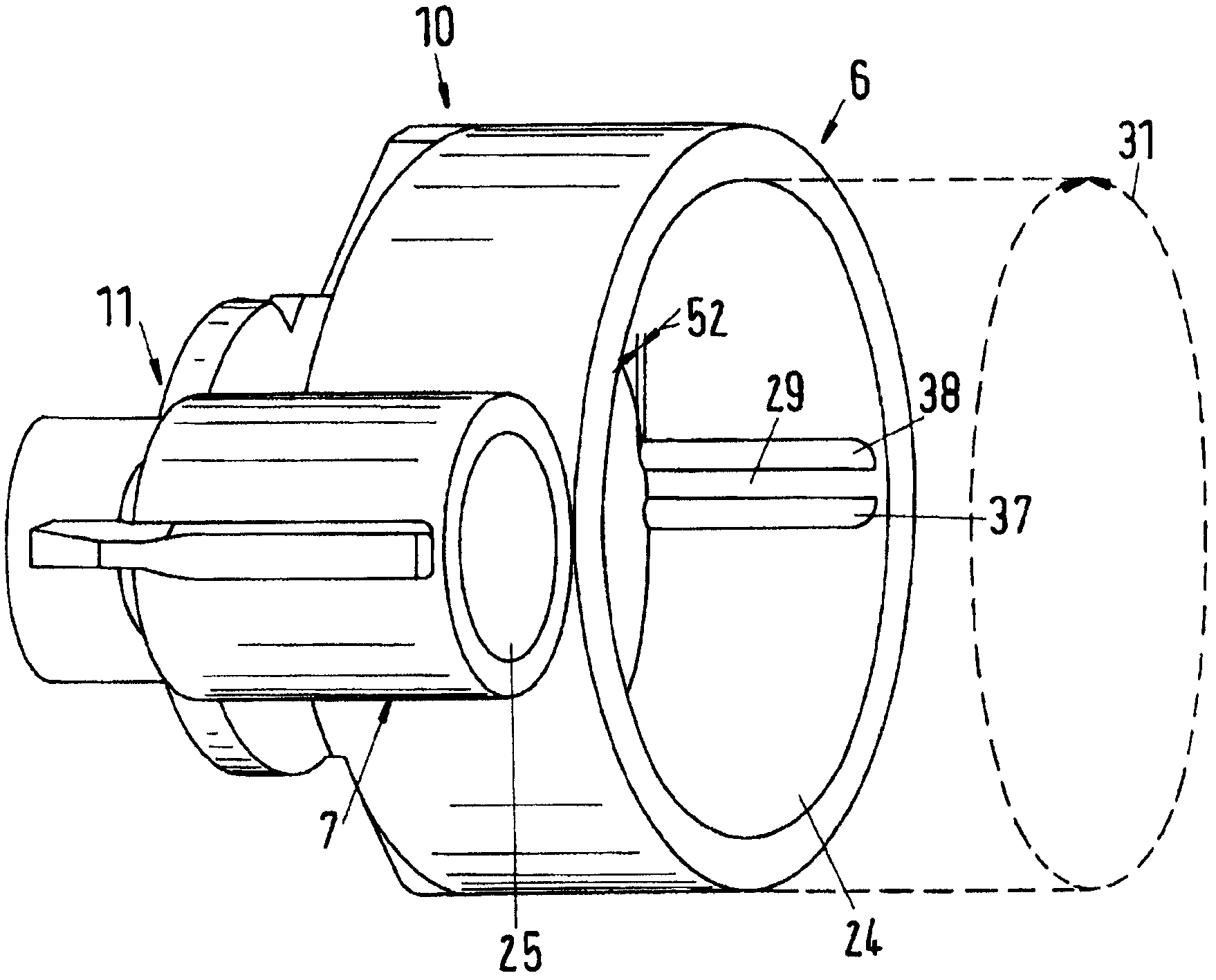

[0030] figure 1A first embodiment of a multicomponent cartridge 1 according to the invention is shown. In particular, such multi-component cartridges are intended to contain metered filling materials comprising at least two components, which are not allowed to come into contact with each other prior to their joint use. The multicomponent cartridge 1 comprises a first storage chamber 6 for a first component 8 , a second storage chamber 7 for a second component 9 . The first storage chamber 6 is separated from the second storage chamber 7 such that the two components do not come into contact with each other. Such components often interact with each other once they come into contact with each other, wherein chemical reactions may take place. Interaction of components is often a desired effect in an application, however as long as the components are stored this interaction is not desired. Each of the components may of course again comprise a mixture of substances. The multicom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com