Milk product filling equipment with adjustable distance

A technology for filling equipment and dairy products, applied in packaging, food preservation, bottle filling, etc., can solve the problems of low adaptability, inability to meet filling needs, uneven filling, etc., to achieve good sterilization effect, uniform distribution, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

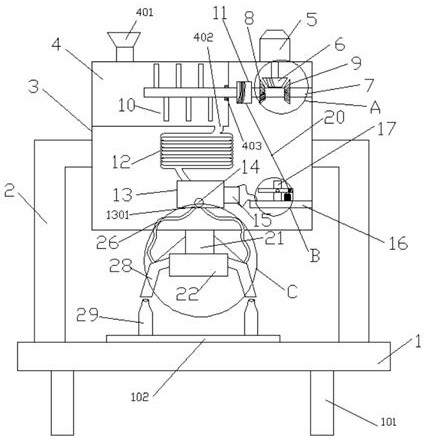

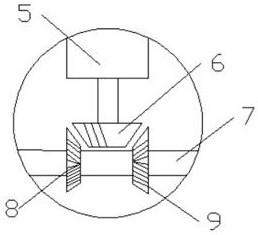

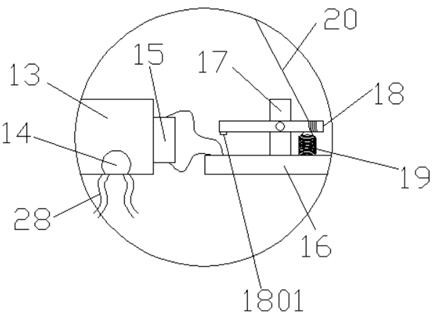

[0031]This embodiment discloses a dairy product filling equipment with adjustable spacing, including a bottom platform 1, a filling box 3, a homogenization bin 4, a reflow heating plate 12, a diversion bin 13 and a filling arm 26, and the bottom platform 1 The support legs 101 distributed in a rectangular array are fixedly installed on the surface, a circular filling platform 102 is movably installed on the upper surface of the bottom platform 1, and a fixed frame 2 is fixedly installed on the upper surface of the bottom platform 1, and the fixed frame 2 and the filling platform 102 On the same axis, a filling box 3 is fixedly installed on the fixed frame 2, a homogeneous warehouse 4 is fixedly installed in the upper left corner of the filling box 3, and an infusion bucket 401 is fixedly connected to the upper surface of the filling box 3, and the infusion bucket 401 is connected to the homogeneous The top plate of the quality bin 4 is connected, the bottom plate of the homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com