A gob-side entry retaining method for three-seam periodical top cutting in the transition support area to form a side of the roadway

A technology of transitional brackets and self-constructed roadsides, applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as difficulty in blocking gangue and complicated construction, and achieve high construction efficiency, control of surrounding rock deformation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

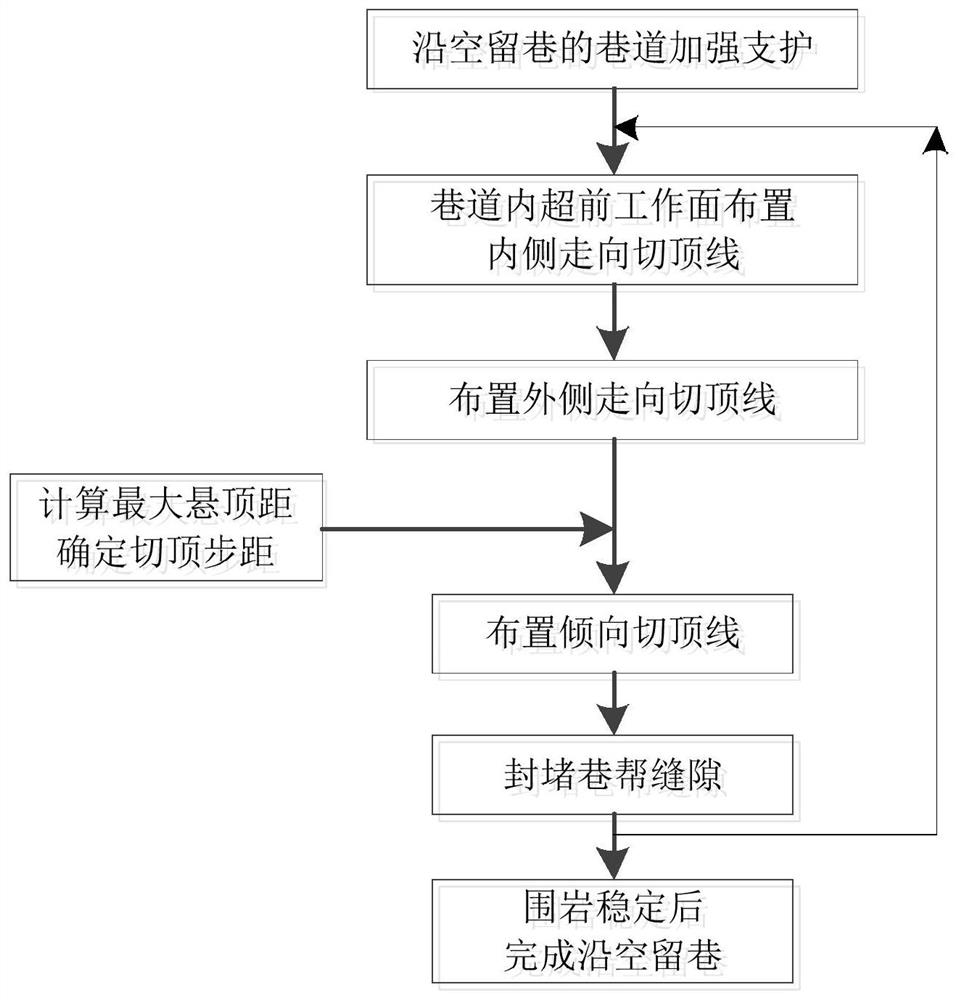

[0034] A gob-side entry retaining method in which the three-seam periodic top cutting in the transitional support area forms the side of the road. The specific construction steps include:

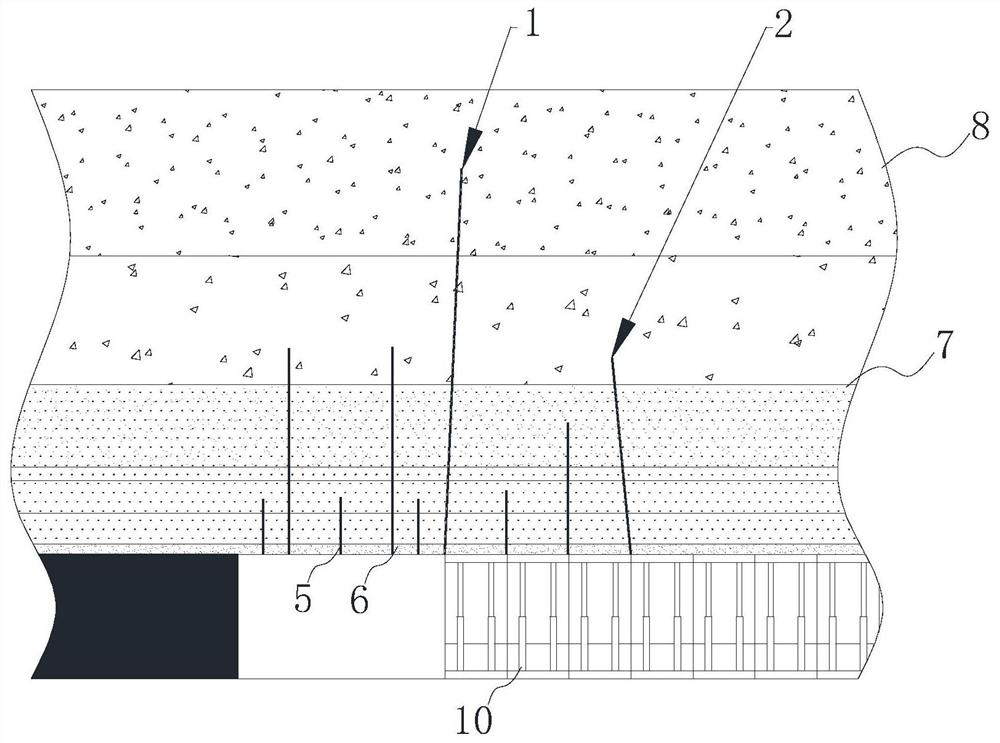

[0035] Step A. Use anchor rods 5 and anchor cables 6 to strengthen the support of the roadway retained along the gob, and install a single hydraulic prop next to the roadway for temporary support. The hydraulic prop adopts a special support to facilitate construction on the roof.

[0036] Step B. In the roadway of the gob-side entry, the advanced position of the working face, the transitional support area of the working face, the inner trending top cutting line 1 is arranged, and the top cutting line can be arranged ahead of the working face in the construction in the roadway, mainly to set the top cutting drilling.

[0037] Among them, the inner trending roof cutting line 1 is arranged in the roadway of the gob-side retaining roadway, the inner trending roof cutting line 1 runs through t...

Embodiment 2

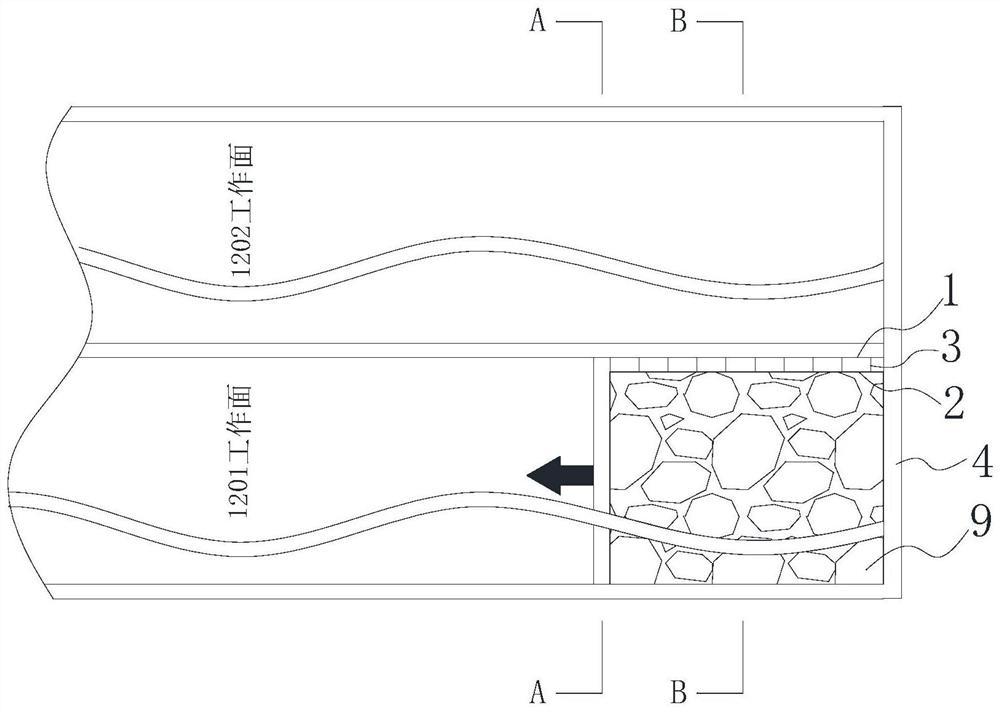

[0053] In order to further illustrate the construction process of the gobside retaining method of three-seam periodic roof cutting and direct roofing in the transition support area, taking the 1201 working face and the 1202 working face of a certain mine as examples, the present invention will be further described in detail.

[0054] The 1201 working face and the 1202 working face of this mine are adjacent to each other. Two coals are mainly mined. The average thickness of the coal seam is 3.2m. Roof strata from bottom to top are sandy mudstone with an average thickness of about 0.8m; fine sandstone with an average thickness of about 2.8m; and siltstone with an average thickness of about 7m. The mining roadway is excavated along the bottom, the section shape is rectangular, and the method of retaining the roadway along the gob is used to set the mining roadway between the two working faces.

[0055] The specific construction steps of carrying out gob-side entry retention by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com