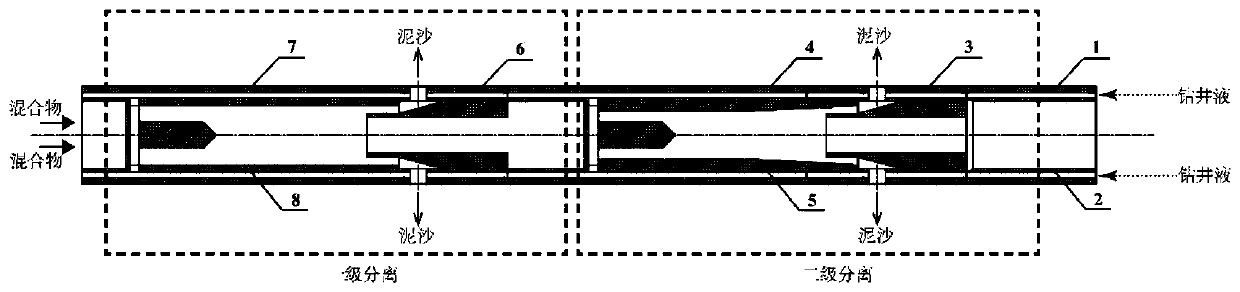

Multiple-stage separator

A technology of separator and cyclone separation, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of small processing capacity, low separation efficiency and easy clogging, and achieve large processing capacity and high separation efficiency. High, the effect of preventing pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

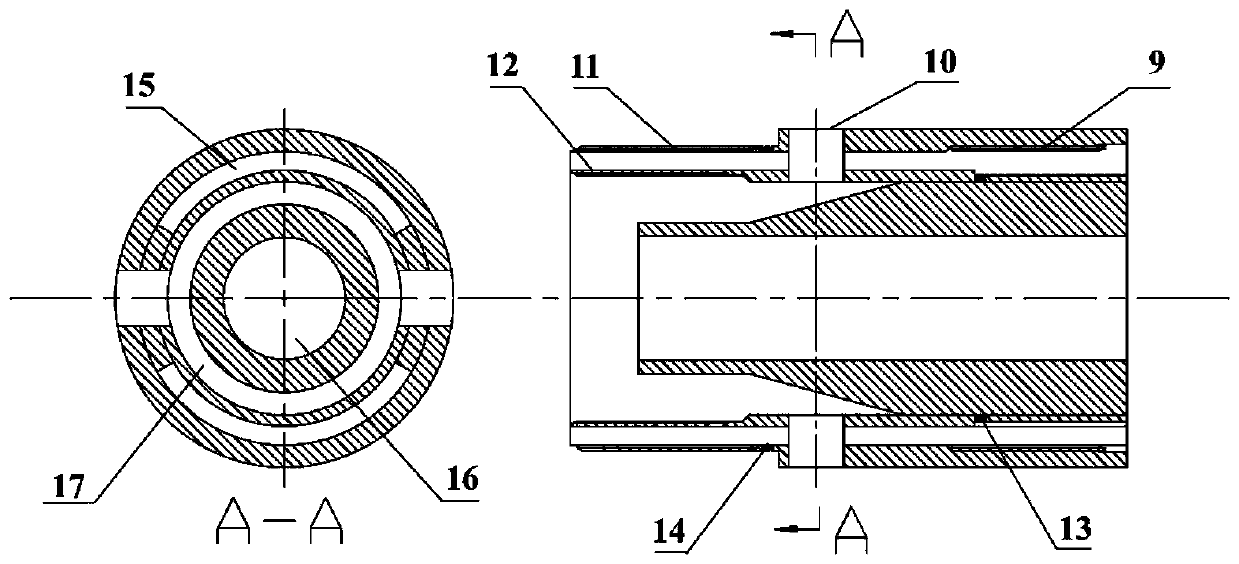

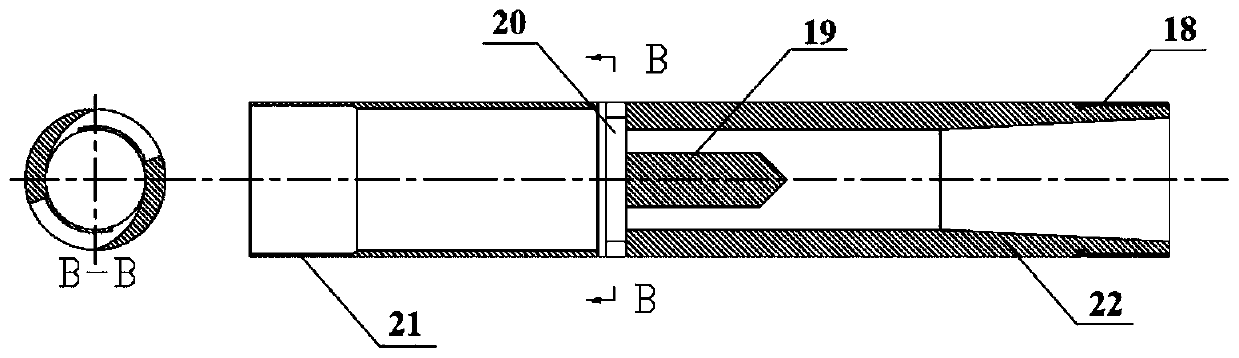

Method used

Image

Examples

Embodiment

[0043] 1. Process flow

[0044] A double-layer coiled tubing drilling process was adopted in a certain natural gas hydrate fluidization production. The tool pipe string from the sea surface to the seabed consists of coiled tubing, the multi-stage separator of the present invention, nozzles, differential pressure sleeves and screw drilling tools. The fluid passes through the multi-stage separator from the annulus (that is, the annulus between the outer pipe and the inner pipe) to the nozzle, and the pressure differential sliding sleeve works during the back-up process of the drilling string, and the drilling fluid is ejected from the nozzle, and the ejected jet is due to It is a high-pressure fluid that can break the hydrate and sediment in the formation into fine particles. The drilling fluid and these fine particles are mixed into a slurry and returned from the inner tube at the bottom.

[0045] 2. Implementation effect

[0046] The returned solid-liquid two-phase flow pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com