A special-shaped three-dimensional shock-isolation bearing

A vibration isolation bearing, special-shaped three-dimensional technology, applied in the fields of environmental vibration, earthquake resistance, and shock absorption, can solve the problems that the performance of the isolation bearing is not stable enough, affect the isolation effect of the vibration isolation bearing, and the production cost is high, and achieve an increase in effective Bearing area, small occupied space, and the effect of improving torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

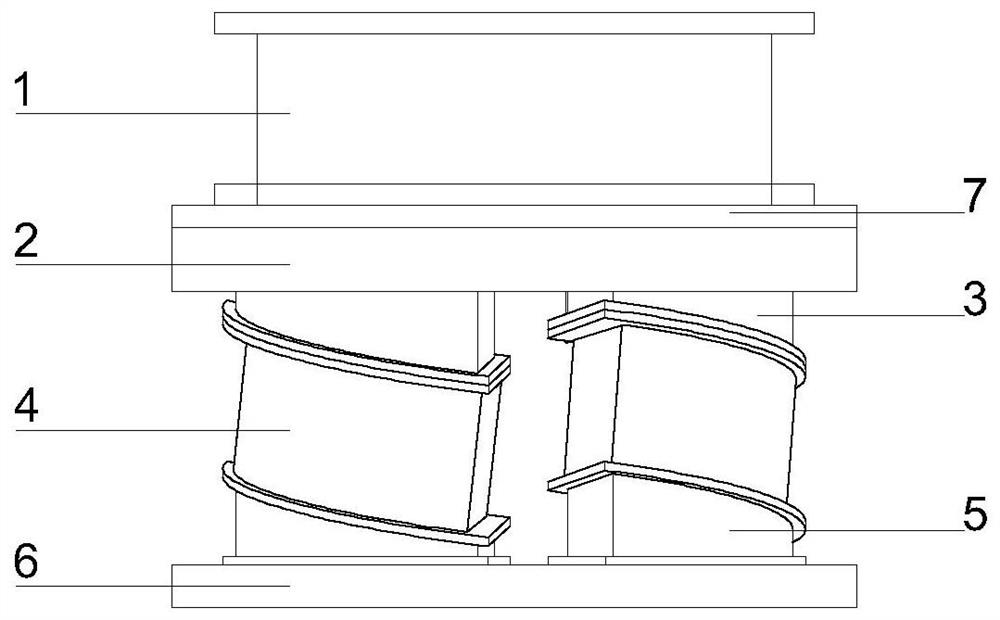

[0054] see Figure 1 to Figure 5 , the special-shaped three-dimensional shock-isolation bearing of the present invention is located between the upper and lower structures that require shock-isolation, and it includes:

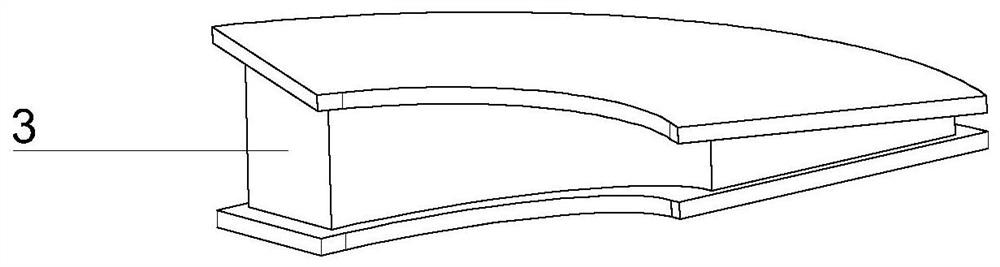

[0055]A bottom plate (6) connected to the lower structure; at least two special-shaped supports (4), composed of parallel upper and lower sealing plates sandwiching the first elastic block; the upper connecting corner block and the lower connecting corner block (3 and 5) has a horizontal bottom surface and an inclined top surface, and when the upper connecting corner block is inverted and the lower connecting corner block is superimposed, the bottom surfaces of the two are parallel; a horizontal support (1), the second elastic block is clamped by the upper and lower plates Consists of: a sliding panel (2); the upper connecting corner block (3) is inverted and sequentially connected with the special-shaped support (4) and the lower connecting corner block (5), a...

Embodiment 2

[0060] see Image 6 and Figure 7 The difference between the second embodiment and the first embodiment is that the special-shaped support is pretreated and pre-deformed so that the upper connecting corner block (3) is inverted and sequentially connected with the special-shaped support (4) and the lower connecting corner block (5). Together, the special-shaped support (4) is placed obliquely relative to the contact slope with the upper and lower connecting corner blocks, and the three are in a vertical state, and the special-shaped three-dimensional shock-isolation support has a regular cylindrical space structure as a whole. The pre-deformation treatment enhances the deformation ability of the special-shaped three-dimensional seismic isolation bearing.

[0061] When the special-shaped support (4) is not pre-deformed, its shape is a spatial winding structure; after the special-shaped support (4) is pre-deformed, its shape is a regular cylindrical space structure.

Embodiment 3

[0063] see Figure 8 , Figure 9 , Figure 10 and Figure 11 The difference between embodiment three and embodiment two is that: for the special-shaped support 4 that adopts pre-deformation treatment, an upright tubular sleeve 9 is fixed on the center of the bottom plate (6), and a columnar rotating guide rail 8 is inserted therein. The upper end of the rotating guide rail 8 passes through the central hole opened by the sliding panel 2 and then touches the bottom of the horizontal support 1. The contact surfaces of the rotating guide rail 8, the horizontal support 1 and the sliding panel 2 are all made of friction materials, and the friction coefficient is within a certain range. change, and place damping material between the rotating rail 8 and the sleeve 9 at the same time. The combined structure of the rotating guide rail (8) and the sleeve (9) acts as a horizontal limit for the special-shaped support (4), and at the same time, a damping material can be placed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com