Camber surface sliding type three-dimension isolation bearing seat

A technology of shock-isolation bearings and curved surfaces, which is applied in the fields of environmental vibration, shock resistance, and shock absorption, can solve problems such as restrictions on large-scale production and use, instability, and the performance of shock-isolation devices cannot be fully utilized, and achieve variable spring stiffness , Stable force performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

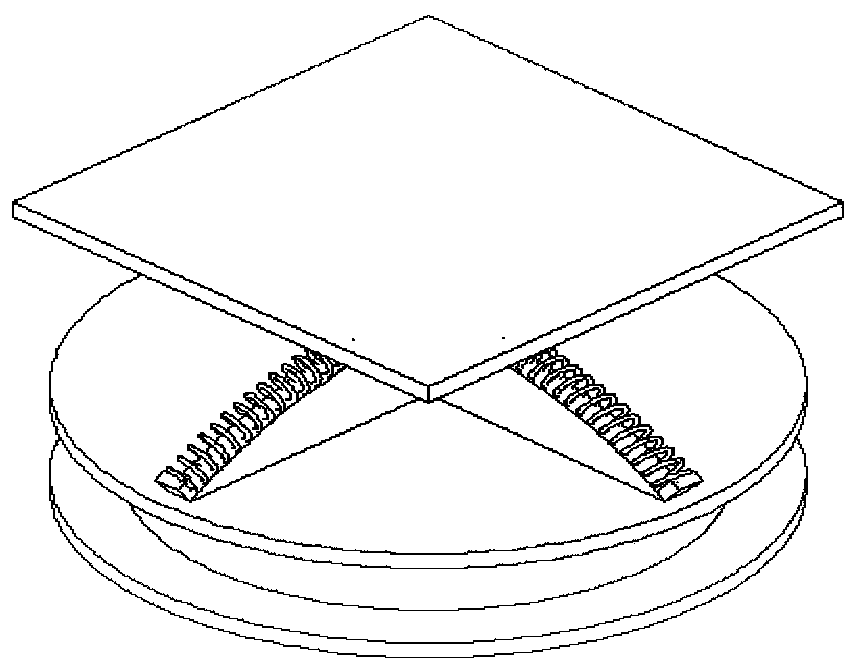

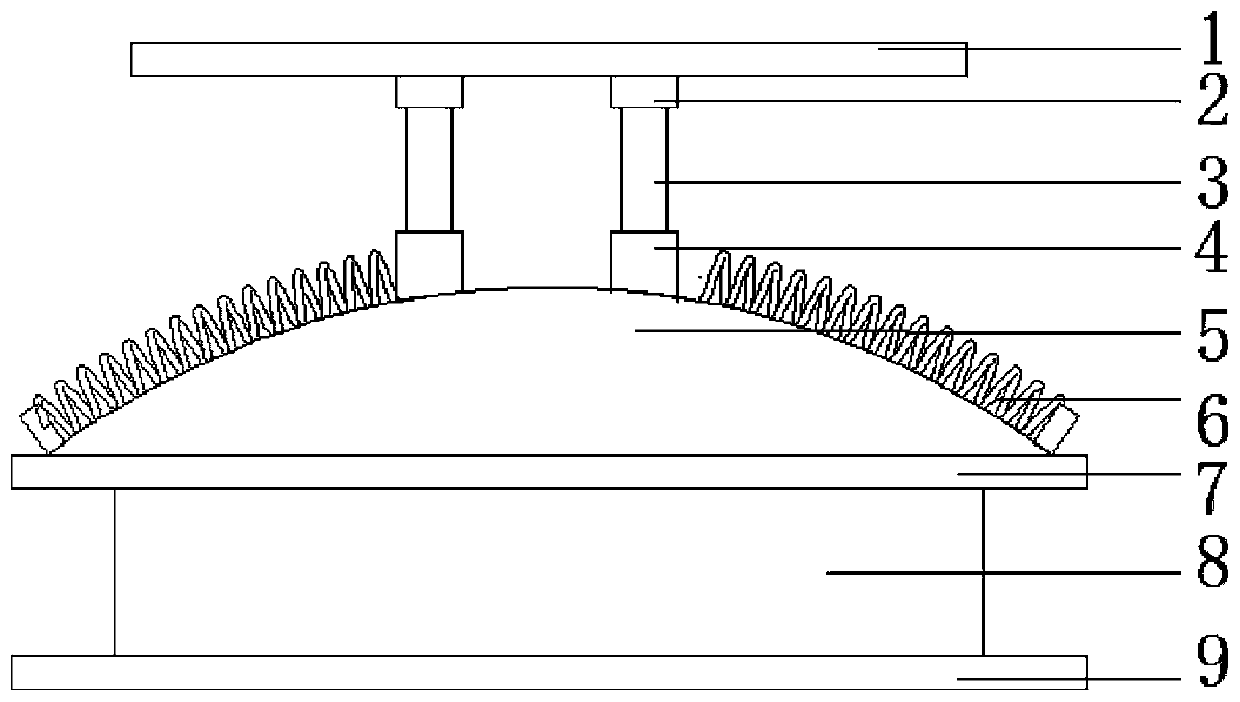

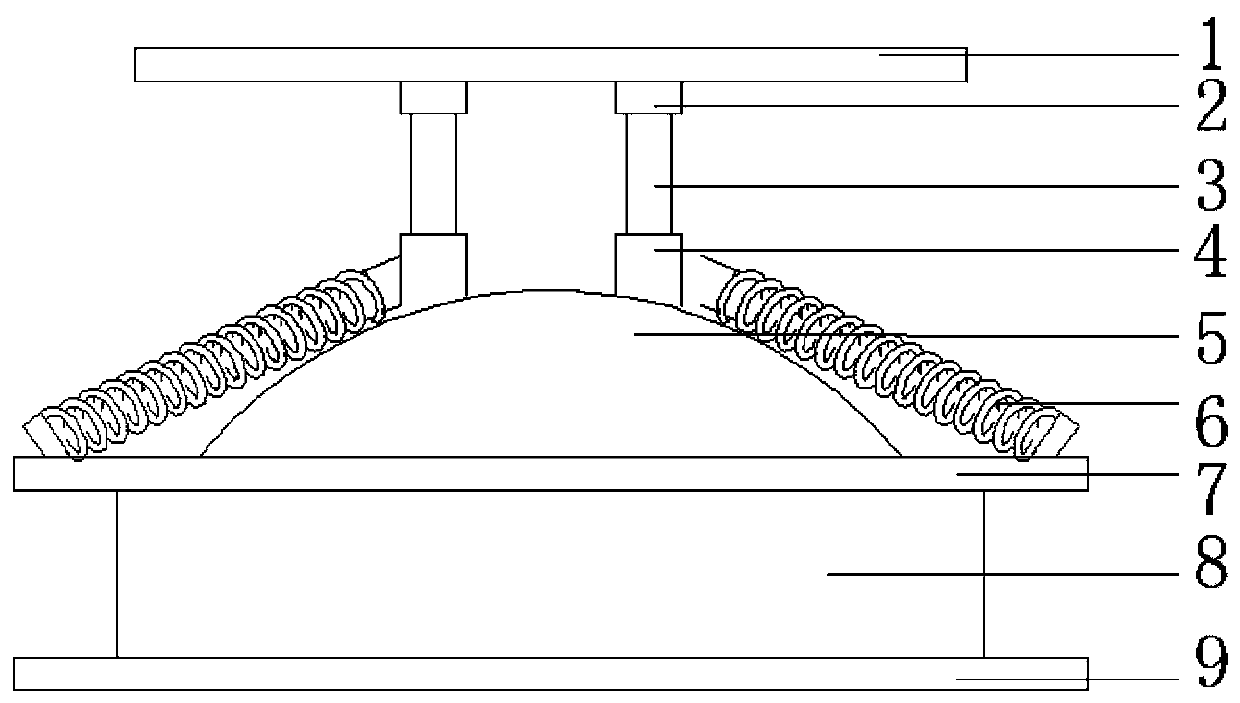

[0037] see figure 1 , figure 2 , Figure 6 , Figure 7 and Figure 8 , Embodiment one of the present invention includes: top plate 1, upper slider 2, connecting rod 3, lower slider 4, arc-shaped slide rail 5, spring 6, connecting plate 7, rubber bearing 8 and bottom plate 9. The arc-shaped slide rail is a vertical plate with a horizontal bottom surface and an arc-shaped top surface, the arc-shaped top surface is provided with a slide rail, and one end of the slide rail is arc-shaped downward to the other end; the upper and lower ends of the connecting rod 3 are respectively connected with The upper slider 2 and the lower slider 4 are fixedly connected, and the top of the upper slider 2 is slidably supported on the bottom surface of the top plate 1 to slide directionally (by being provided with a guide rail or a guide groove to make it directional slide), and the top of the lower slider 4 The lower end is slidably supported on the top slide rail of the arc-shaped slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com