Electrophoresis clamp for car air storage cylinder

An air storage tank and electrophoresis technology, which is applied in electrophoretic plating, electrolytic coating, electrolytic process, etc., can solve the problems of low efficiency, inability to ensure uniform coating of the inner cavity, labor and time consuming, etc. Transport and manufacture convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

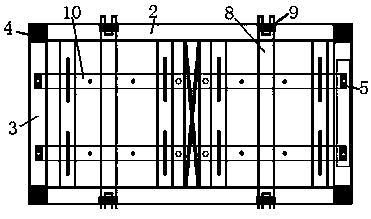

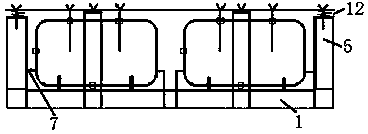

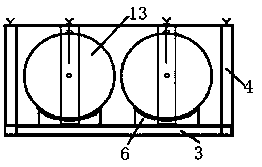

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an electrophoretic fixture for an automobile air tank according to the present invention includes a base 1, and the base 1 is welded by two longitudinal beams 2 and six beams 3, and the four corners and the middle positions of the base 1 are Eight columns 4 are established, four support plates 5 are arranged on the two outer beams 3 of the base 1, and four pairs of parts seats 6 are arranged on the middle beam 3 of the base 1. 6. Limiting parts 7 are provided at both ends, and a binder plate 8 is provided on the column 4 in the middle of the base 1. The binder plate 8 is connected to the column 4 through bolts 9. The binder plate 8 is arranged in parallel with the beam 3 , an electrode rod mounting plate 10 is provided between the support plates 5 in the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com