Aluminum electrolysis anode hollow aluminum pouring steel claw

A technology of aluminum electrolytic anode and empty steel claw, which is applied in the field of electrolytic aluminum anode steel claw, can solve the problems of high resistivity, large current empty consumption, high production cost, etc., and achieve the effect of reducing power loss, reducing production cost and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

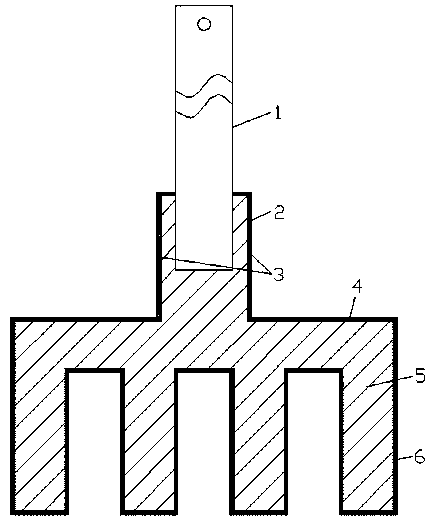

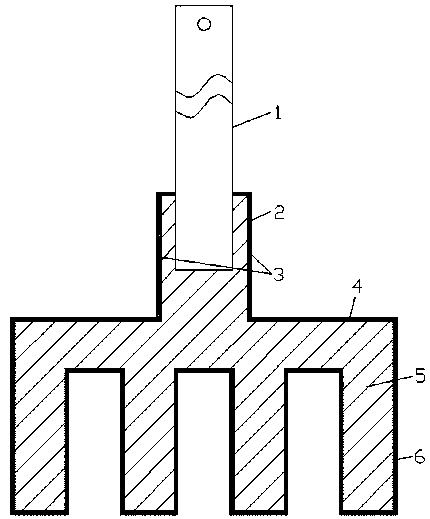

[0020] Example. A hollow aluminum-injected steel claw for an aluminum electrolytic anode, which is composed of figure 1 As shown, it includes a hollow steel claw steel shell 2, the upper end of the hollow steel claw steel shell 2 is provided with an aluminum guide rod connecting plug 3, the lower end of the hollow steel claw steel shell 2 is provided with a steel claw beam 4, and the lower end of the steel claw beam 4 is provided with a set of The steel claw foot 6, the steel claw beam 4 and the steel claw foot 6 are hollow structures, and the aluminum guide rod connection plug 3 on the hollow steel claw steel shell 2, the steel claw beam 4 and the steel claw foot 6 are filled with an aluminum core 5.

[0021] An aluminum guide rod 1 is arranged inside the aluminum guide rod connection plug 3 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com