Ventilating anti-drag support column structure for supercavity surface vehicle

A pillar structure and surface boat technology, applied in the direction of ships, hydrodynamic characteristics/hydrostatic characteristics, hulls, etc., can solve the problem of low drag reduction effect, achieve the goal of reducing resistance, avoiding unstable navigation status, and preventing deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

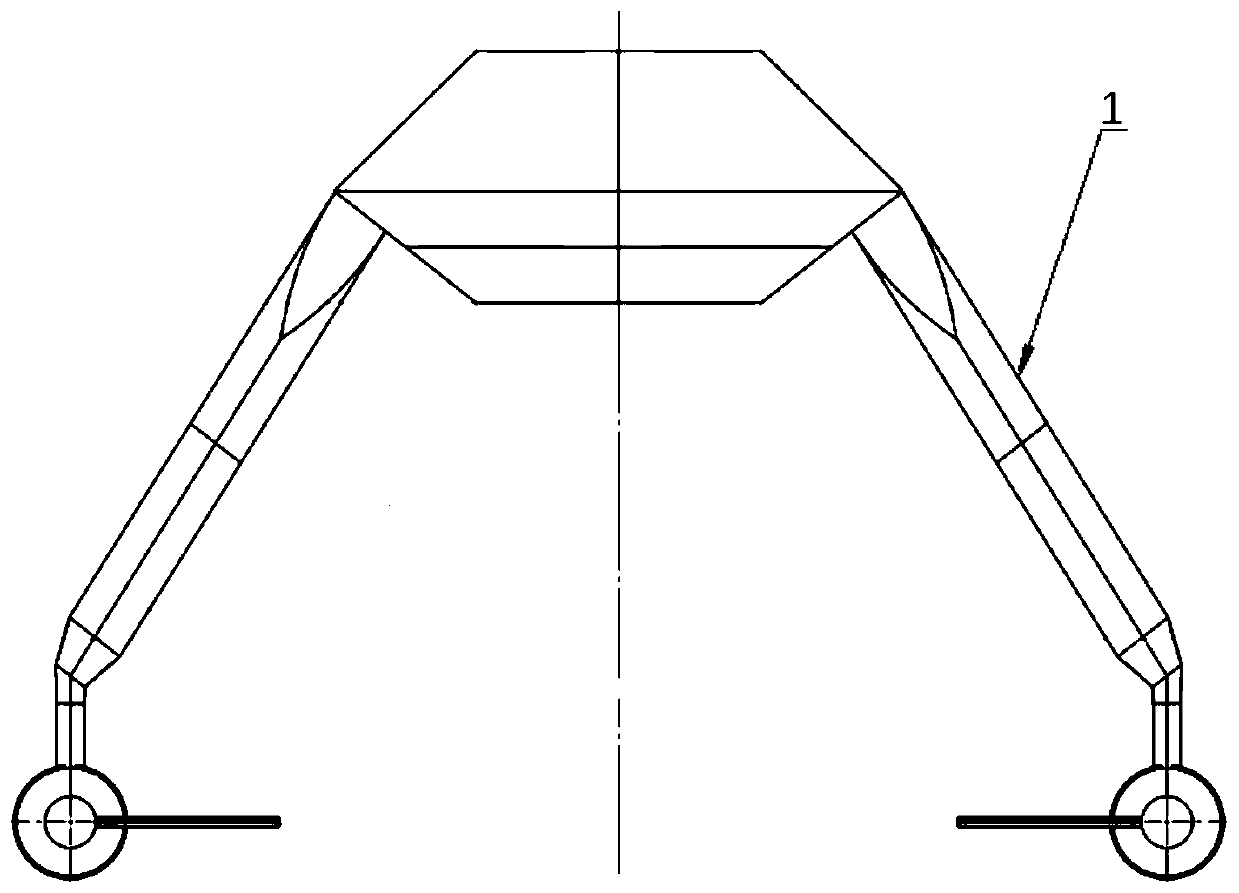

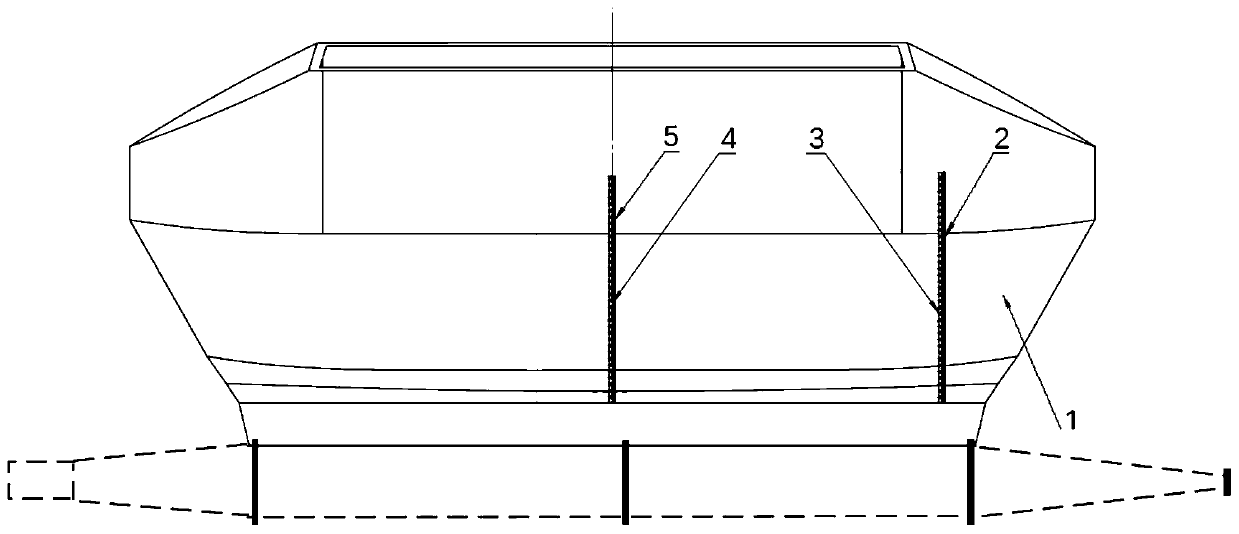

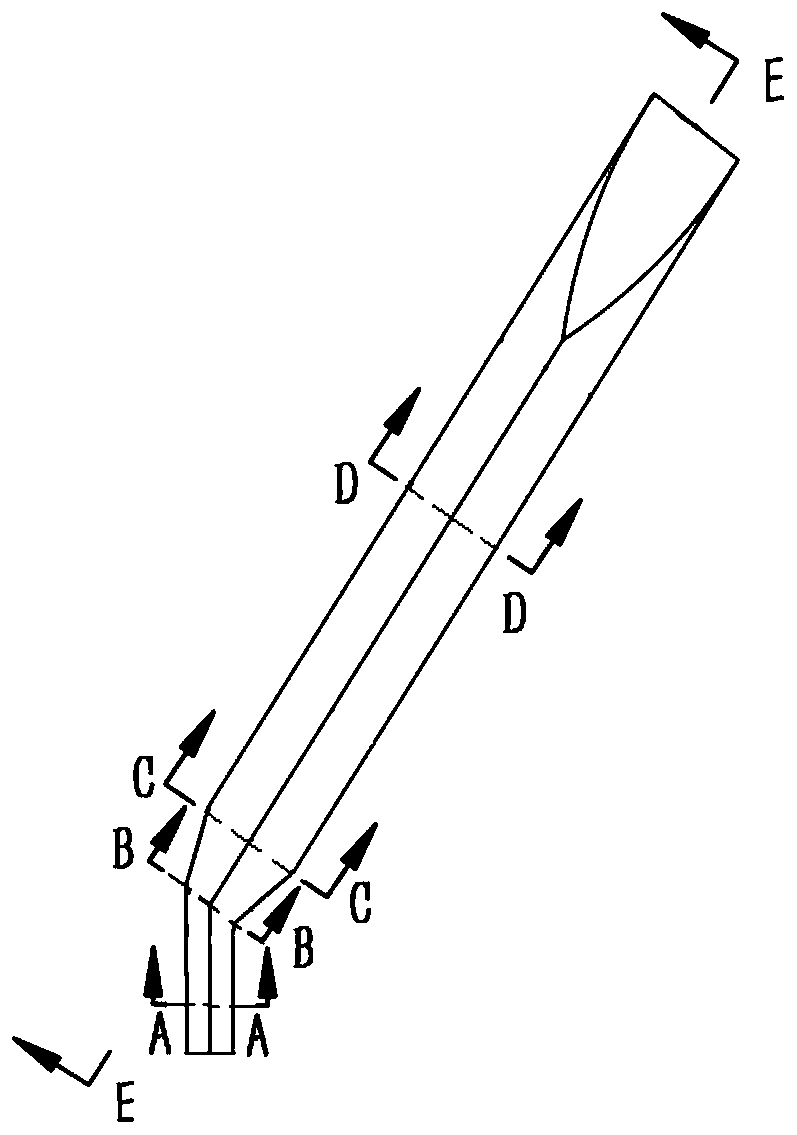

[0025] The specific names of each number in the attached drawings are as follows: 1-pillar shell; 2-front-end cavitator; 3-front-end vent; 4-middle cavitator; Groove; 8-pillar internal framework; 9-pillar internal wire groove connected to the submerged body; 10-cavitation generated by ventilation.

[0026] The present invention provides a ventilation strut structure that can achieve a further drag reduction effect compared with the prior art, by arranging vent holes and cavitators on both sides of the strut, and performing auxiliary ventilation to generate cavities to further reduce the frictional resistance on the strut surface . Because the underwater submerged body of the supercavitating surface boat produces cavitation, and considering that the cavitation of the pillar cavitation and the cavitation of the underwater submerged bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com