Thermal fabric having spontaneous heating function

A self-heating, fabric technology, applied in the field of thermal fabrics, can solve the problems of low wearing comfort, insufficient wool feeling, and the sanding process is not properly optimized, and achieves good effects of improving thermal insulation, bacteriostatic and antibacterial effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A heat-retaining fabric with self-heating function includes a flame-retardant layer and a heat-retaining layer, and the heat-retaining layer is located on the lower end surface of the flame-resisting layer.

[0019] The flame retardant layer includes 70 parts by weight of flame retardant waste silk fiber, 10 parts by weight of antistatic fiber and 20 parts by weight of polyester fiber, and the thermal insulation layer includes 43 parts by weight of heating fiber material and 57 parts by weight of bamboo fiber, including the following preparation steps :

[0020] Step 1. Put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into distilled water for soaking and cleaning for 25 minutes, and then put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into the mixing tank Stir, the stirring speed is 300r / min, the temperature is 200°C, and the time is 55min, then the mixture is poured into the spinneret for spinning, the spinni...

Embodiment 2

[0028] A heat-retaining fabric with self-heating function includes a flame-retardant layer and a heat-retaining layer, and the heat-retaining layer is located on the lower end surface of the flame-resisting layer.

[0029] The flame-retardant layer includes 83 parts by weight of flame-retardant waste silk fibers, 10 parts by weight of antistatic fibers and 20 parts by weight of polyester fibers, and the thermal insulation layer includes 55 parts by weight of heating fiber materials and 45 parts by weight of bamboo fiber, including the following preparation steps :

[0030] Step 1. Put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into distilled water for soaking and cleaning for 35 minutes, and then put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into the mixing tank Stir, the stirring speed is 600r / min, the temperature is 60°C, and the time is 55-75min, then pour the mixture into the spinneret for spinning, the spinn...

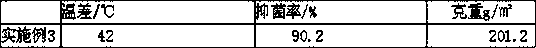

Embodiment 3

[0038] A heat-retaining fabric with self-heating function includes a flame-retardant layer and a heat-retaining layer, and the heat-retaining layer is located on the lower end surface of the flame-resisting layer.

[0039] The flame-retardant layer includes 70 parts by weight of flame-retardant waste silk fiber, 13 parts by weight of antistatic fiber and 17 parts by weight of polyester fiber, and the heat-retaining layer includes 46 parts by weight of heating fiber material and 54 parts by weight of bamboo fiber, including the following preparation steps :

[0040] Step 1. Put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into distilled water for soaking and cleaning for 28 minutes, and then put the flame-retardant waste silk fiber, antistatic fiber and polyester fiber into the mixing tank Stir, the stirring speed is 400r / min, the temperature is 220°C, and the time is 60min, then the mixture is poured into the spinneret for spinning, the spinneret ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com