Automatic pop-rivet drilling device for door plate

A door panel, drilling position technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of unguaranteed safety production, high manufacturing cost, low production efficiency, etc., and achieves excellent practicability and economy. Design flexibility and produce efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

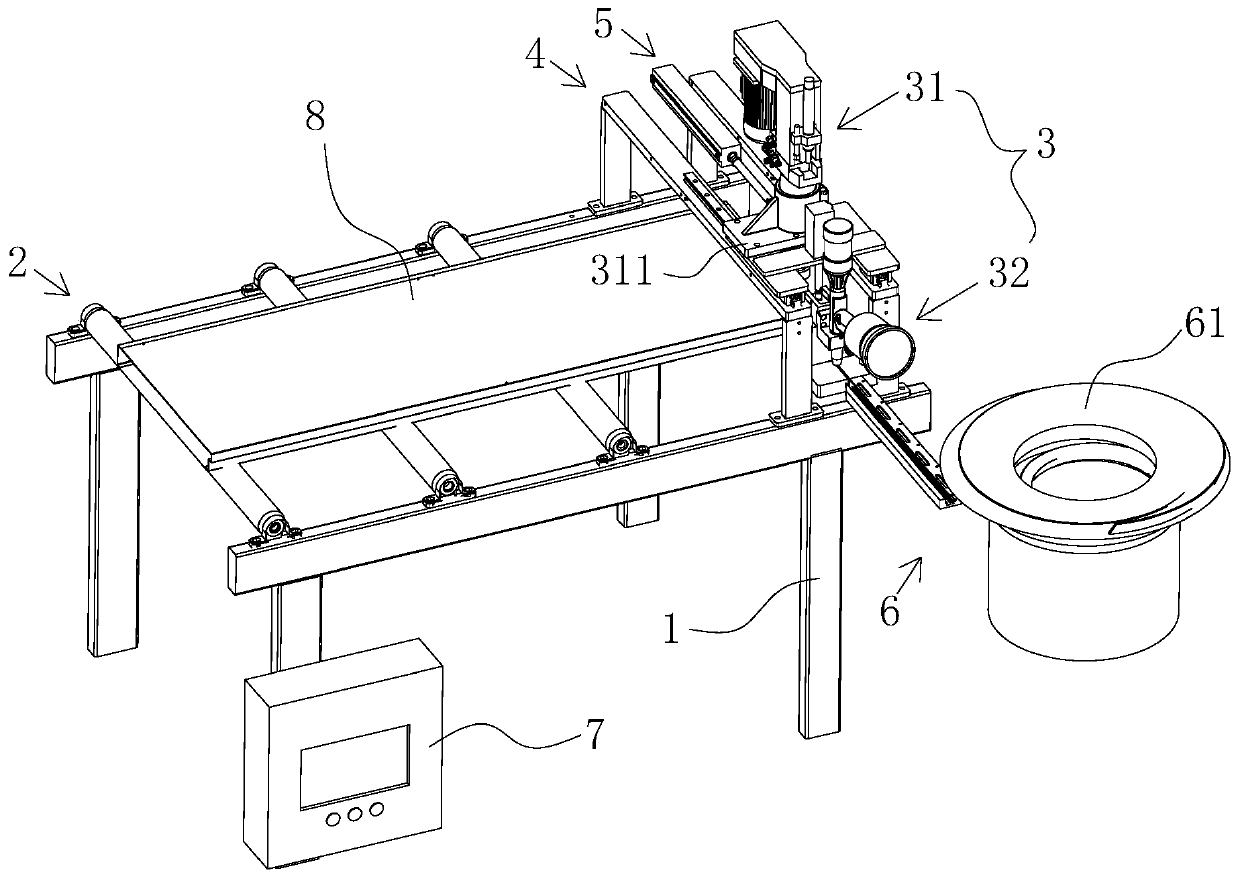

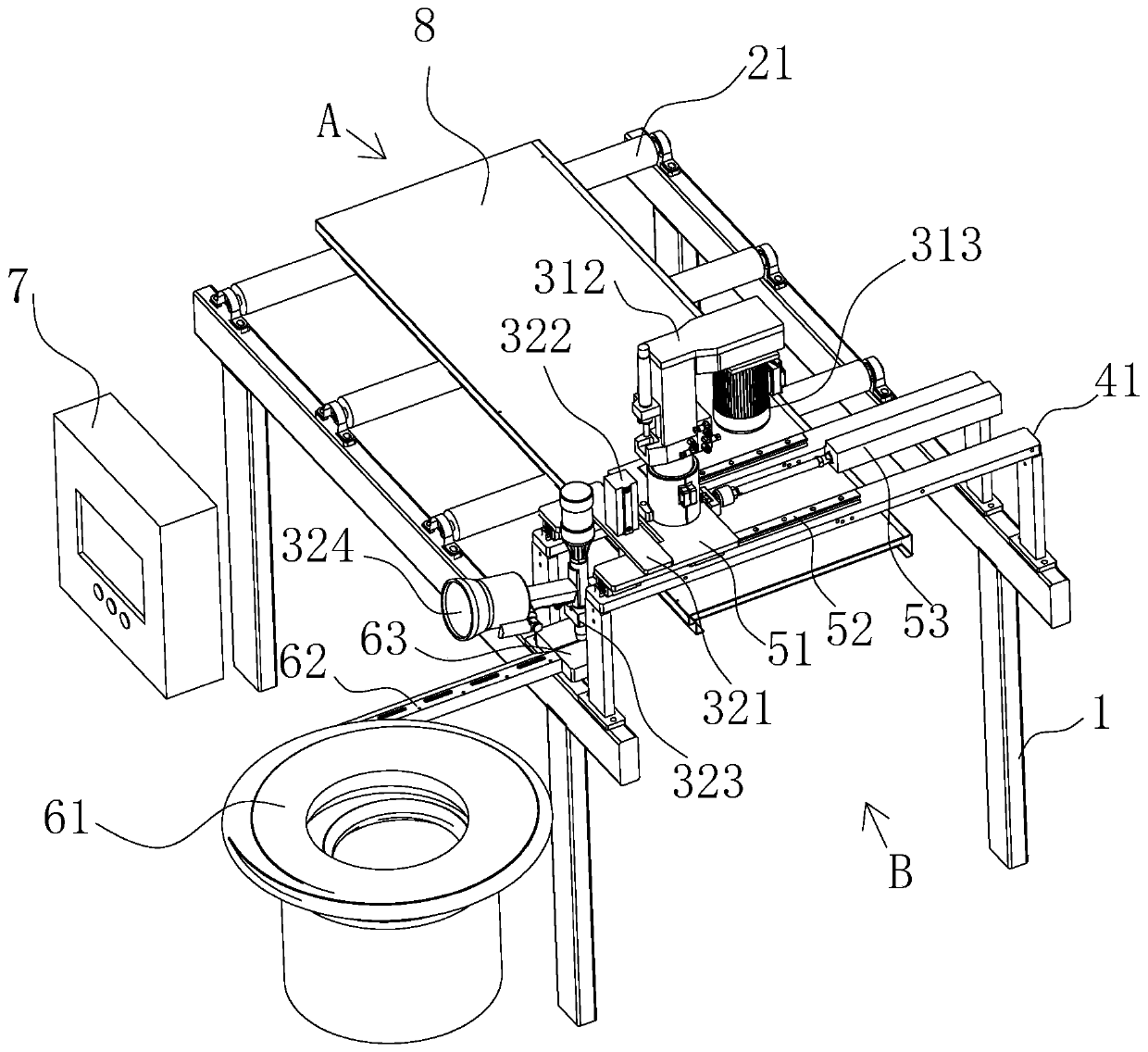

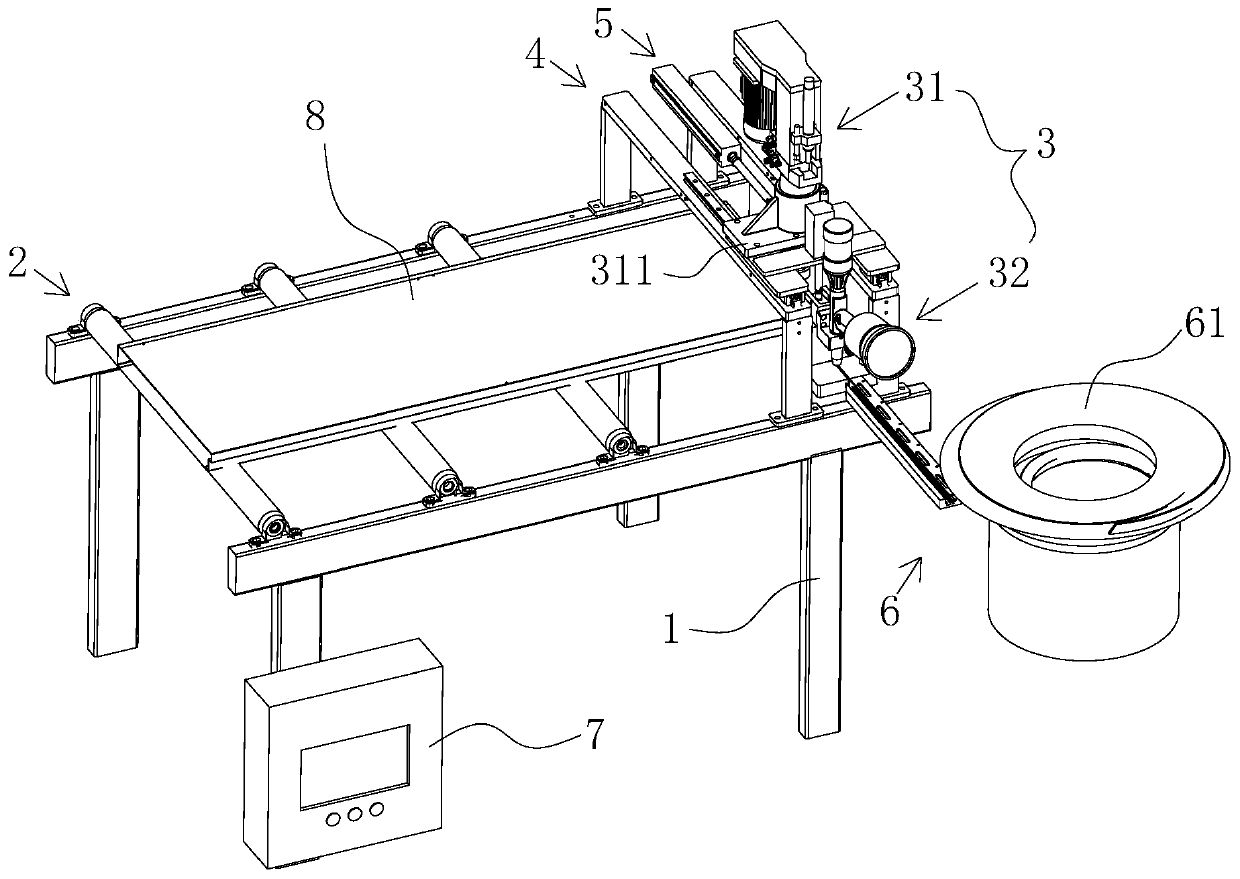

[0043] Such as Figure 1-2 As shown, the preferred automatic drilling and pulling nail device for door panels provided in this embodiment includes: the machine base 1 is provided with a conveying roller platform 2 which is driven by a roller 21 to transport the workpiece door panel, and one end of the machine base 1 is set on the conveying roller The upper end of the table 2 is the feed inlet A, the other end of the machine base 1 where the crossbeam installation mechanism 4 is set is the discharge outlet B, and the crossbeam installation mechanism 4 is provided with two crossbeam brackets 41 erected on the upper end of the machine base 1 side, so that the crossbeam Between the brackets 41, there is a working space arranged on the upper end of the machine base 1 to provide the drilling mechanism 31 and the nail pulling mechanism 32, and the pushing mechanism 5 cooperates to realize drilling and pulling the nails. In the action space set between the two beam brackets 41 , the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com