Catalyst for preparing propylene by propane dehydrogenation and preparation method of catalyst

A propane dehydrogenation and catalyst technology, applied in catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of poor propylene selectivity, large pore diameter, poor hydrothermal stability, etc., and achieve long mission life, wide application prospects, excellent The effect of anti-carbon properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

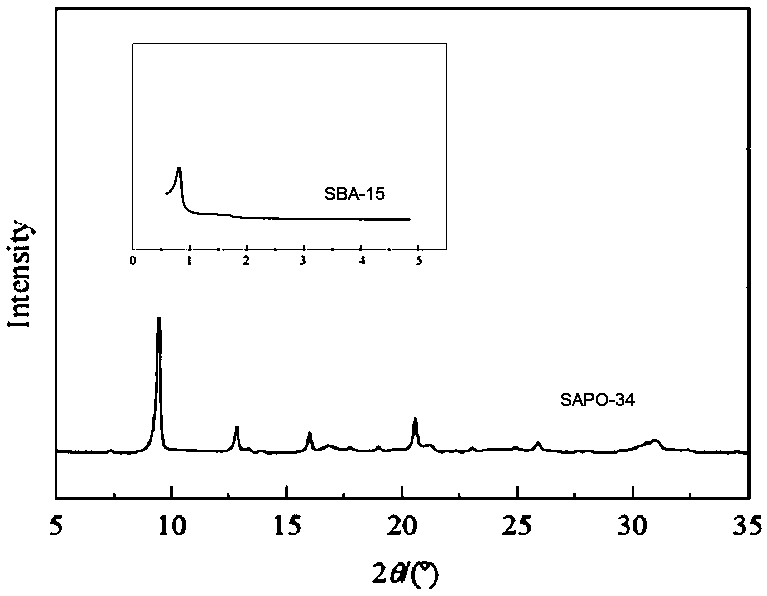

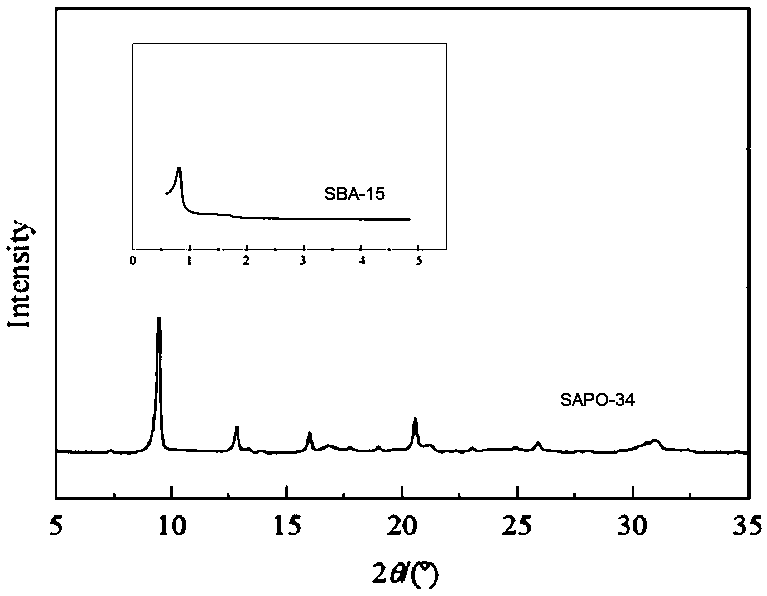

[0025] (1) Pseudo-boehmite, orthophosphoric acid, silica sol and triethylamine are proportioned to Al 2 O 3 :P 2 O 5 :SiO 2 :R:H 2 O=1:1:0.6:2.2:55 Stir the reaction at room temperature to form a gel, age for 18h, transfer it into a hydrothermal reaction kettle with a Teflon lining, and pre-crystallize at 200°C for 12h to obtain a reaction slurry ( 1); Dissolve a certain amount of P123 in the HCl aqueous solution with a concentration of 2mol / L, add tetraethyl orthosilicate TEOS, the mass ratio of P123 and TEOS is 0.6, stir for 10h, and the mixture is transferred into the lining with polytetrafluoroethylene In the hydrothermal reaction kettle, pre-crystallized at 100 ℃ for 12h to obtain slurry (2); the obtained slurry (1) and slurry (2) were mixed at a mass ratio of 1:0.3, and transferred into a PTFE-lined In a hydrothermal reaction kettle, crystallize at 200°C for 12h, and the obtained precipitate is washed with deionized water and absolute ethanol, suction filtered, drie...

Embodiment 2

[0029] In addition to impregnating Pt and Sn, the catalyst was also impregnated in alkali metal K solution, and the specific preparation process was the same as that in Example 1. The catalyst is denoted as CAT-2, and the composition is: Pt0.02wt%, Sn0.5wt%, K1wt%, and the rest is carrier Al-SBA-15-SAPO-34; the carrier composition is the same as that of Example 1.

Embodiment 3

[0031] The main composition of the catalyst is the same as that of Example 1, but SBA-15 accounts for 25% and SAPO-34 accounts for 75% by weight in the eutectic micro-mesoporous molecular sieve, which is recorded as CAT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com