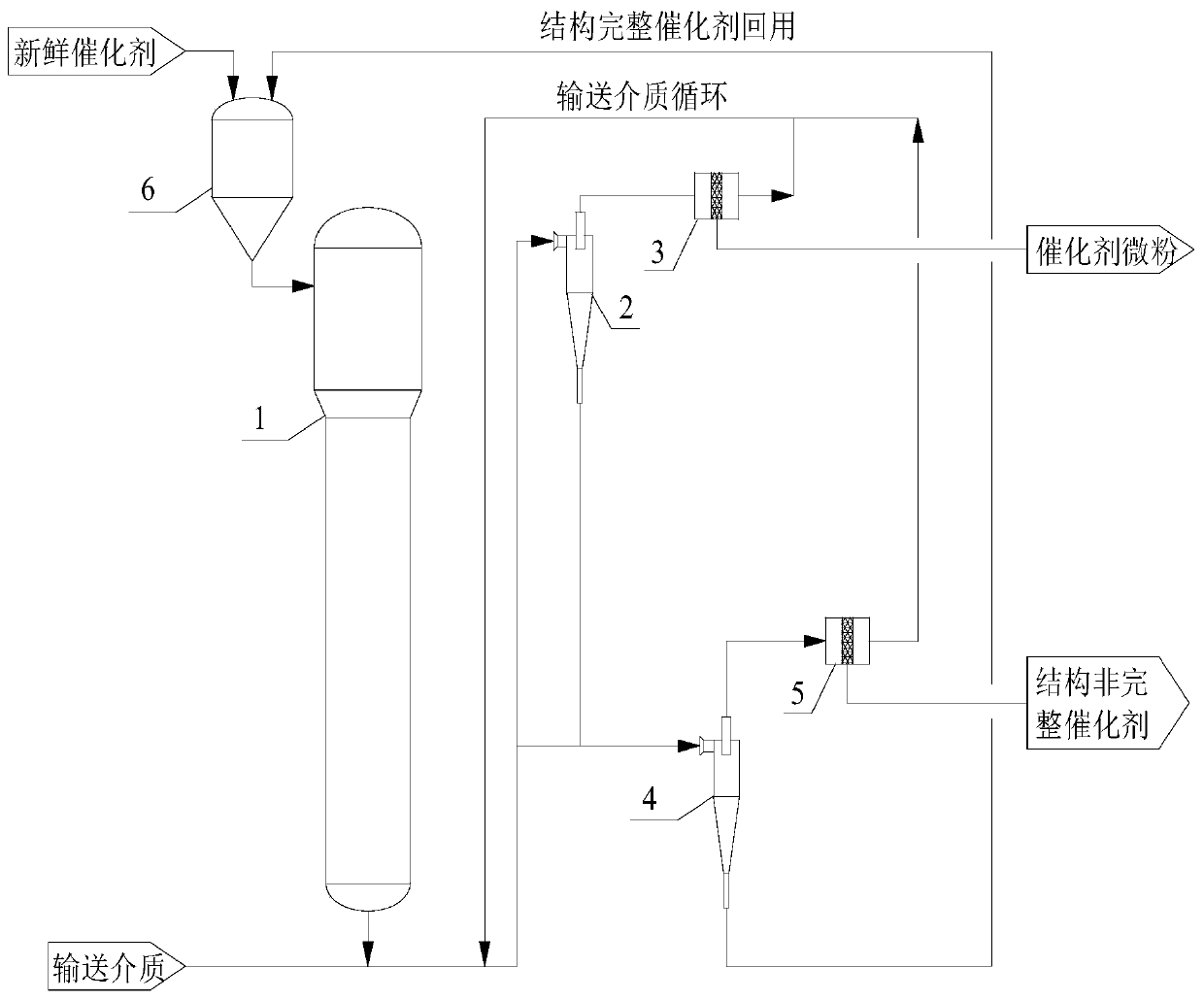

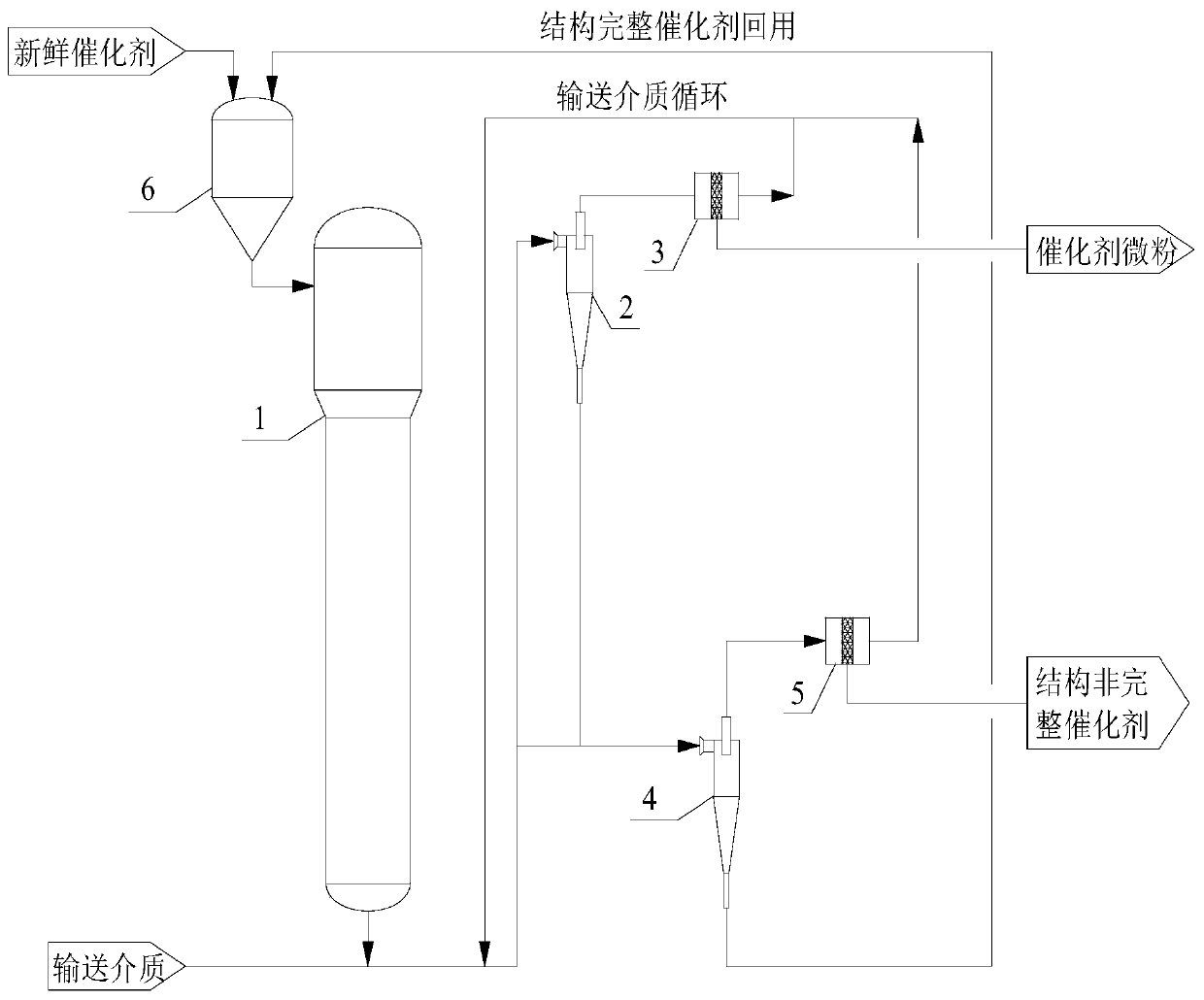

Method and device for removing particles in biomass pyrolysis liquid fluidized bed reactor

A technology of ebullated bed reactor and biomass pyrolysis, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of inability to achieve catalyst particle classification, complex process, and inability to achieve catalyst drying reduction to reduce the risk of coking, protect the environment and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The present invention is further described below in conjunction with specific examples. For the experimental methods without specific conditions indicated in the following examples, the conventional conditions or the conditions suggested by the manufacturer are usually followed. All percentages and parts are by weight unless otherwise indicated.

[0040] 30,000 tons / year biomass pyrolysis fluid ebullating bed hydrogenation unit discharges 30kg / h of oil-containing catalyst online, including 15kg / h of oil, about 1kg / h of catalyst powder, about 2kg / h of structurally incomplete catalyst, and about 12kg of structurally complete catalyst / h. According to the method and device of the present invention, the particles in the ebullated bed reactor of biomass pyrolysis liquid are removed, and its specific operation process and effect are described as follows:

[0041] 1) Implementation process

[0042] Implement with reference to the method of the present invention, specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com