Cold application patch and production device thereof

A production device and cold compress technology, applied in lamination devices, layered products, and other household appliances, can solve the problems of cumbersome processing and high production costs, and achieve the effect of reducing operation process, reducing processing flow, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

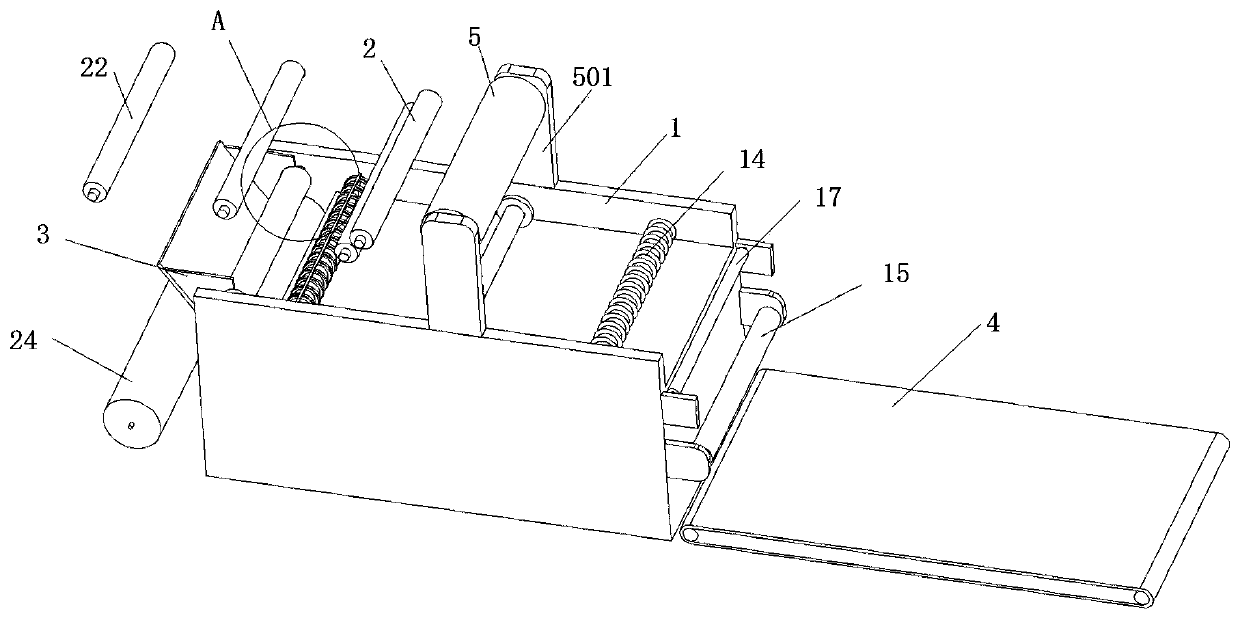

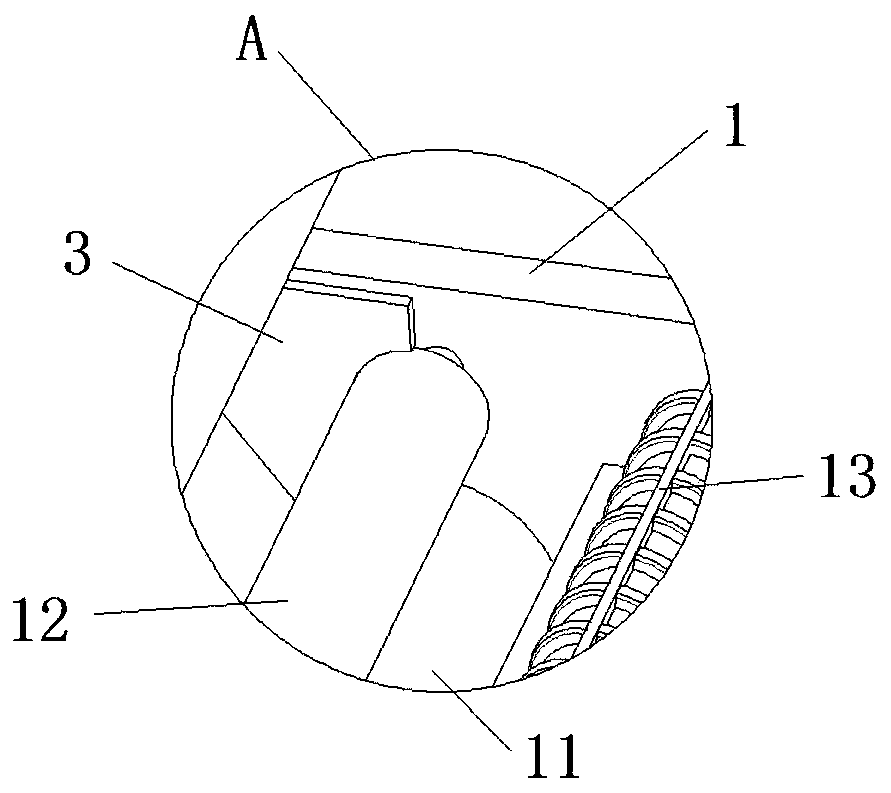

[0048] like figure 1 As shown, this embodiment provides a production device for cold compresses, including a machine base body 1 , a separation mechanism 2 , and a feeding mechanism 3 ; the left side of the machine base body 1 is provided with a transmission mechanism 6 .

[0049] Supports 501 are arranged on both sides of the frame body 1, and an unwinder 5 is fixed on the upper part of the support 501. The unwinder 5 rolls the backing tape into the separation mechanism 2, and the separation mechanism 2 separates the backing tape. There are two parts: the upper non-woven glue coating layer 901 and the lower isolation layer 902.

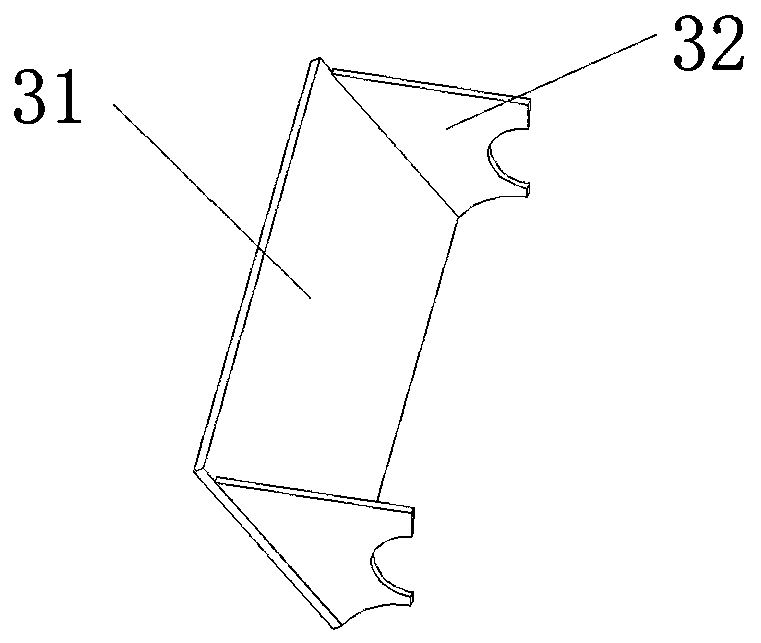

[0050] like figure 2 As shown, one end of the base body 1 is provided with a feeding mechanism 3, including a baffle plate 31 and a support plate 32. The bottom of the support plate 32 fits with the surface where the driving roller 11 and the pressure roller 12 are located, and is arranged on both sides. Side position, the baffle plate 31 is obli...

Embodiment 2

[0060] like Figure 8-9 As shown, this embodiment provides a production device for cold compresses, including a machine base body 1, a separation mechanism 2, and a feeding mechanism 3. The structure and working principle of its components are the same as those in Embodiment 1. The upper part of the machine base body 1 is fixed by There is a first unwinding machine 51, a second unwinding machine 52 is fixed on the side, and an unwinding roller 24 is arranged at the bottom of the machine base body 1; the first unwinding machine 51 rolls the backing adhesive tape into the separation mechanism 2, And the backing tape is separated into two parts, the lower isolation layer 902 and the upper non-woven adhesive layer 901.

[0061] One end of the base body 1 is provided with a feeding mechanism 3, the bottom is provided with a pressure roller 12, and the bottom of the pressure roller 12 is provided with a driving roller 11, and the upper end surface of the base body 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com