Method for repairing performance of retired lithium ion battery

A lithium-ion battery and performance technology, which is applied in the field of repairing the performance of decommissioned lithium-ion batteries, can solve the problems of insufficient improvement in battery cycle life and service performance, insufficient uniformity, and compactness, and achieve good battery consistency, battery capacity and Improved cycle performance and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

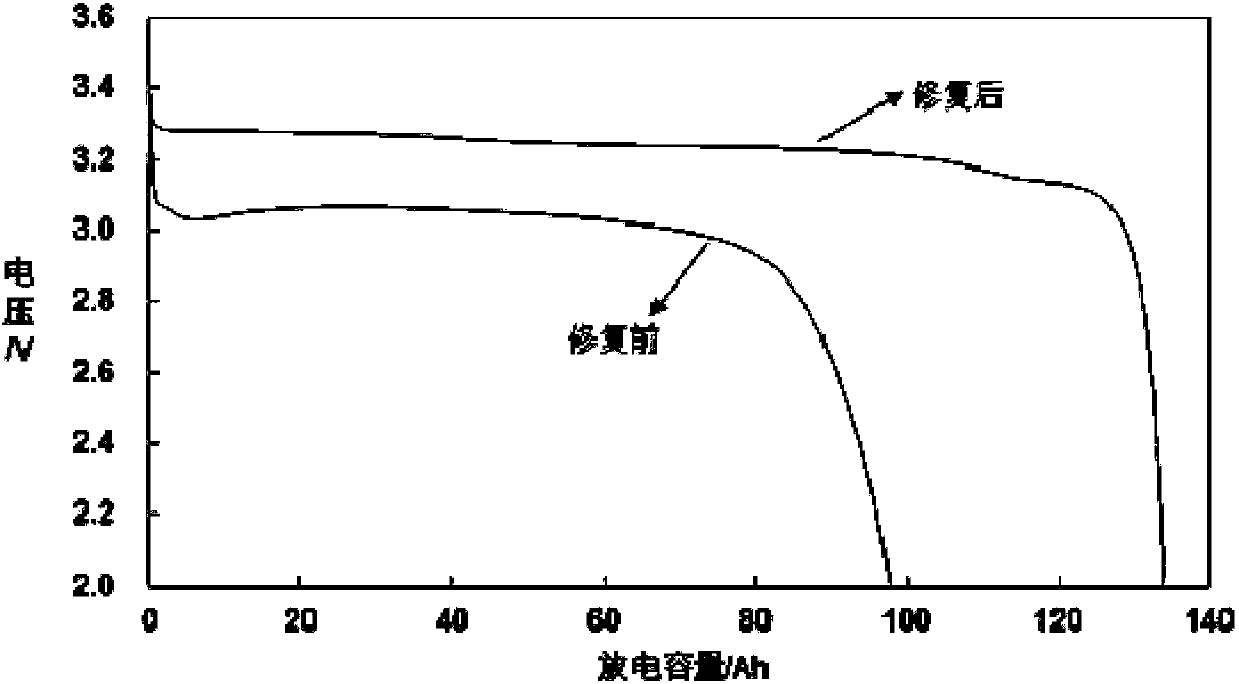

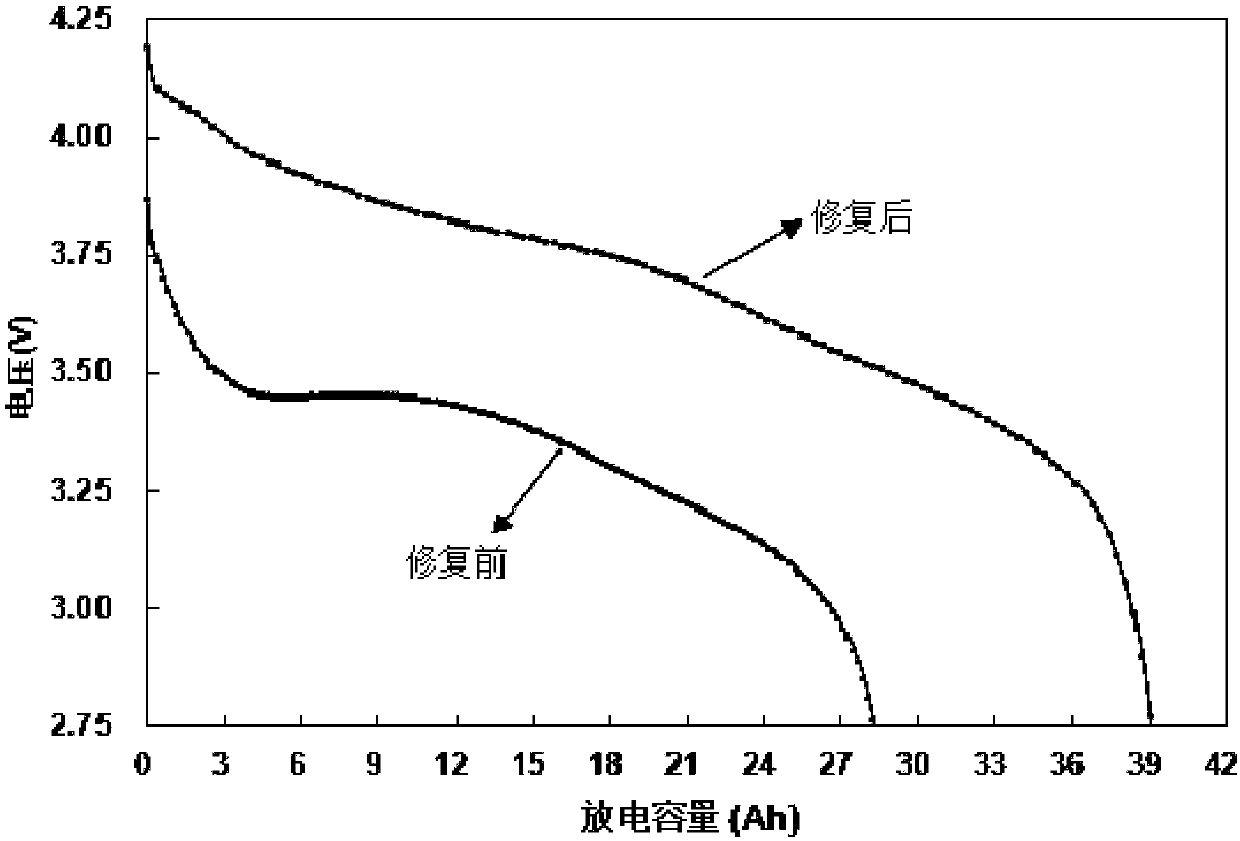

[0043] Example 7: After sample F was used, the battery was discharged to 2.75V at a constant current of 21A, and the battery capacity C0 decayed to 29Ah, which was 69.0% of the initial rated capacity C (42Ah). Then, in a constant 45°C aging room, the battery was charged at a constant current and constant voltage of 8.4A (0.2C) for 500 minutes, the cut-off current was 0.84A, and the charging upper limit voltage was 4.2V; then, in an aging room at the same temperature, Discharge at a constant current of 8.4A (0.2C) to 2.75V; repeat this, charge and discharge cycle 3 times, and the repair is complete.

[0044] In a normal temperature environment, charge the repaired battery to 4.2V with a constant current of 21A and a cut-off current of 0.84A, and then discharge it to 2.75V with a constant current of 21A. The discharge capacity C1 of the battery is 39Ah, and the capacity C1 recovers to 92.9% of the initial rated capacity C after restoration, which is an increase of 23.9%. For th...

Embodiment 8

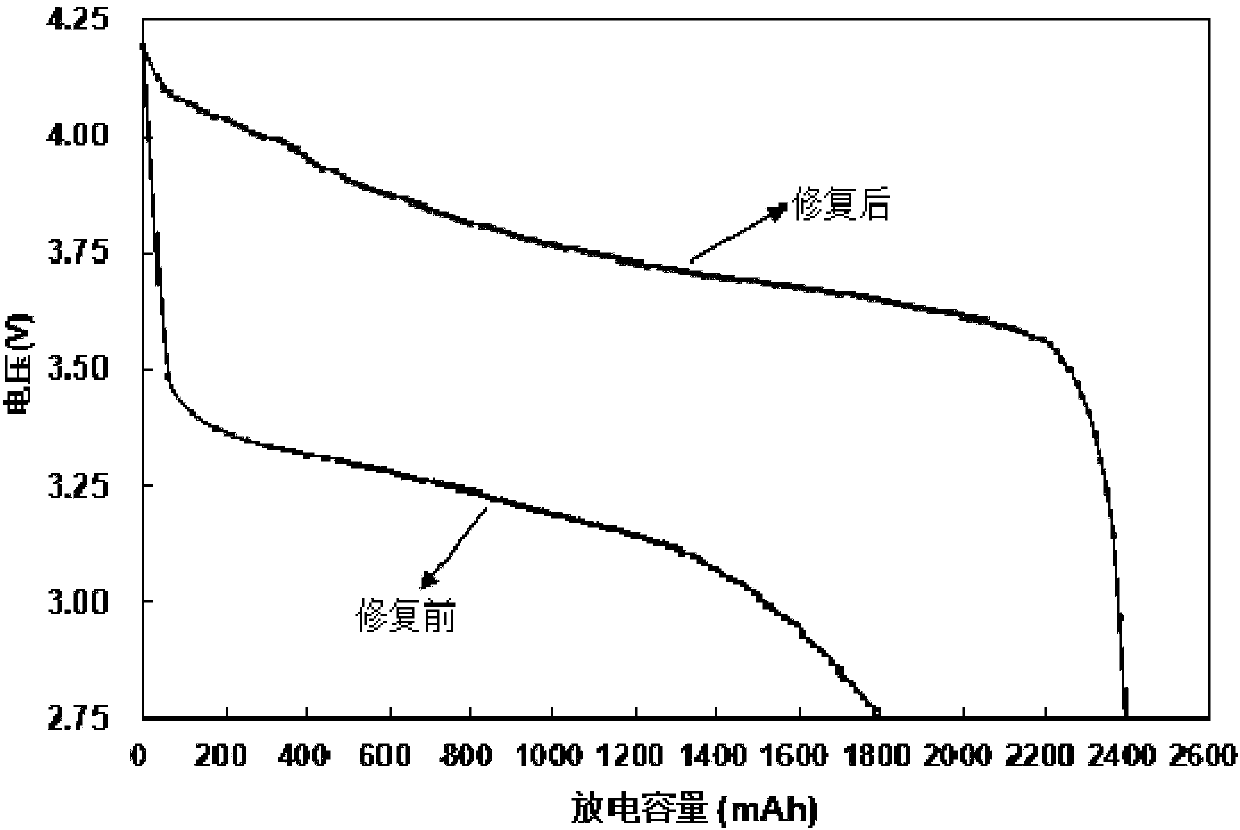

[0046] Example 8: After sample L was used, the battery was discharged to 2.75V at a constant current of 1.3A, and the battery capacity C0 decayed to 1.8Ah, which was 69.2% of the initial rated capacity C (2.6Ah). Then, in a constant 45°C aging room, the battery is charged at a constant current and constant voltage of 0.52A (0.2C) for 500 minutes, the cut-off current is 0.052A, and the charging upper limit voltage is 4.2V; then, in an aging room at the same temperature, Discharge at a constant current of 0.52A (0.2C) to 2.75V; repeat this, charge and discharge cycle 3 times, and the repair is complete.

[0047] In a normal temperature environment, charge the repaired battery to 4.2V with a constant current of 1.3A and a cut-off current of 0.052A, and then discharge it to 2.75V with a constant current of 1.3A. The discharge capacity C1 of the battery is 2.4Ah, and the capacity recovers to 92.3% of the initial rated capacity C after restoration, an increase of 23.1%. For the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com