Packaging structure and packaging method of image sensor

An image sensor and packaging structure technology, which is applied to electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve the problems of difficulty in ensuring the yield of packaging products, reducing the yield of packaging products, and degrading sensing performance, etc., to improve efficiency. , the effect of easy packaging and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

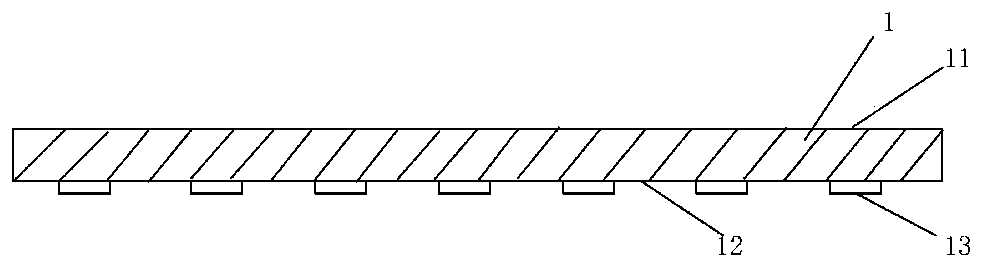

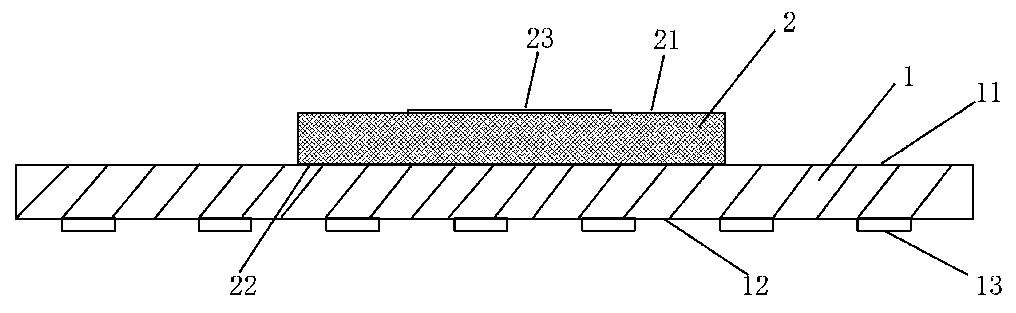

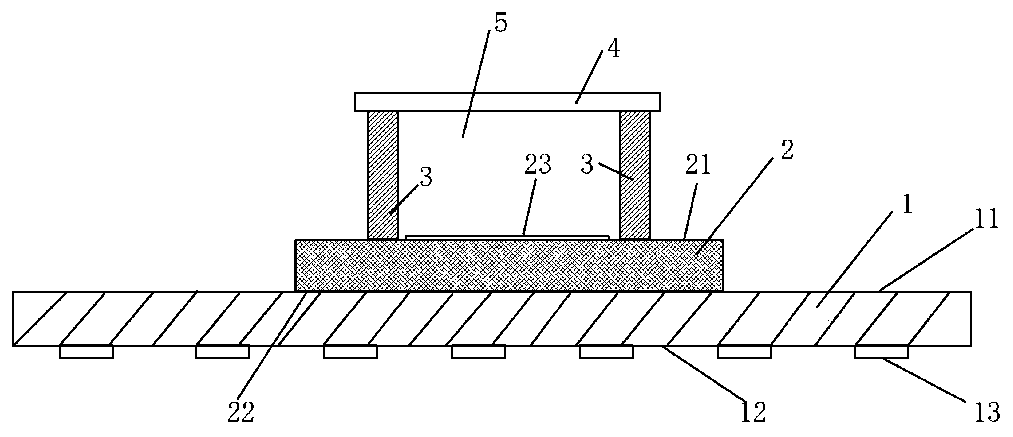

[0048] refer to Figure 1A-1F As shown, the image sensor packaging structure provided by Embodiment 1 of the present invention includes:

[0049] A substrate 1, the substrate 1 comprising a first surface 11 and a second surface 12, the second surface 12 is opposite to the first surface 11;

[0050] Image sensor 2, the image sensor 2 is fixed on the substrate 1, the image sensor 2 includes a photosensitive area 23, and the side on which the photosensitive area 23 is set on the image sensor 2 is the upper surface of the image sensor 2 21. The side opposite to the upper surface 21 is the lower surface 22 of the image sensor 2;

[0051] A transparent cover plate 4 is bonded above the image sensor 2, and the image sensor 2 receives sensing signals through the transparent cover plate 4, and the side bonded on the transparent cover plate 4 is the transparent cover The bottom surface of the plate 4, the side opposite to the bottom surface of the transparent cover plate 4 is the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com