CFD-based simulation analysis method for thermal sterilization process of liquid canned food

A canned food, simulation analysis technology, applied in the field of simulation analysis of the thermal sterilization process of liquid canned food, can solve the problems of ignoring the influence of heat transfer in the headspace, not considering the phenomenon of liquid evaporation and condensation, and inaccurate calculation of the minimum sterilization value, etc. To achieve the effect of optimizing the sterilization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

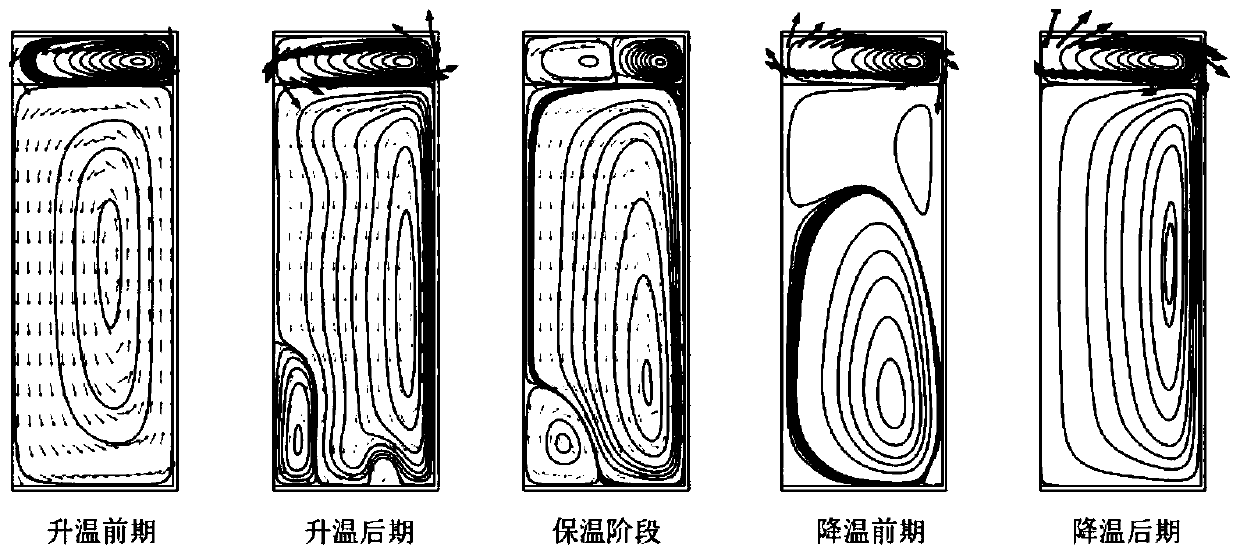

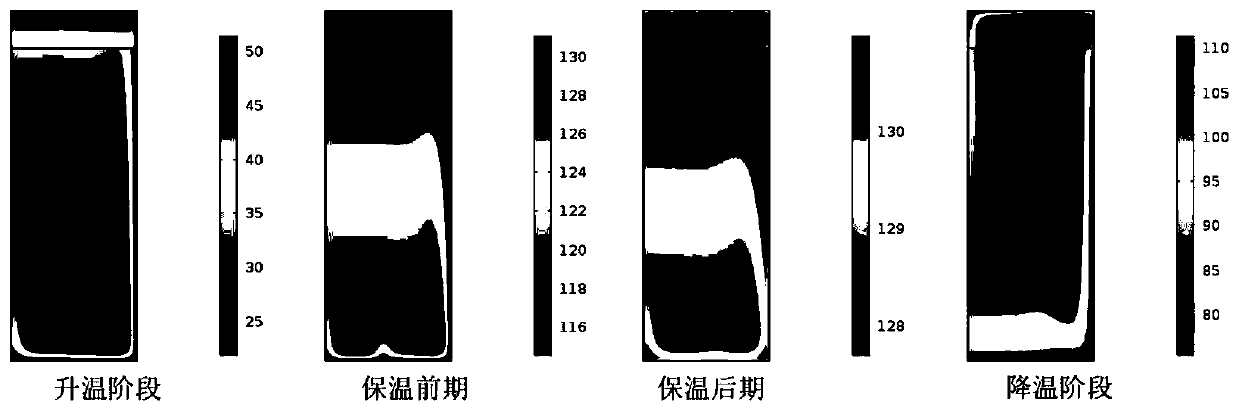

[0024] The technical scheme adopted in the present invention is a simulation analysis method based on CFD technology to analyze the thermal sterilization process of liquid canned food, and the specific steps include:

[0025] a. Based on the liquid canned food to be analyzed and the thermal sterilization process to be analyzed, collect data, simplify the processing, and establish a canned heat transfer model; specifically:

[0026] The canned food to be analyzed is a 1.0% CMC solution that can be used to simulate the thermal sterilization process of liquid canned food. It is packed in canned food with can number 7113, and the density, dynamic viscosity, heat capacity at constant pressure, and thermal conductivity are obtained through measurement and parameter fitting. The coefficients as a function of temperature are shown in Table 1.

[0027] Table 1 Thermophysical parameter characteristics of 1.0% CMC solution

[0028]

[0029] The geometric dimensions of the can are: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com