Prefabricated combined wall of civil building

A civil building, prefabricated technology, applied in the direction of buildings, building components, building types, etc., can solve problems such as unclean environmental protection, inconvenient disassembly, complex structure, etc., and achieve simple structure, easy installation and disassembly, and good controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

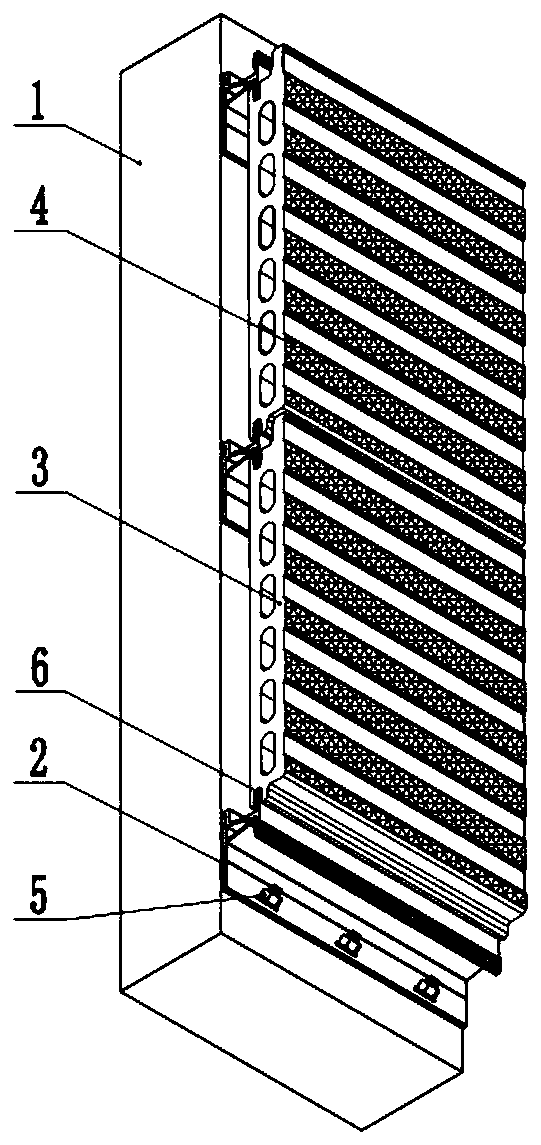

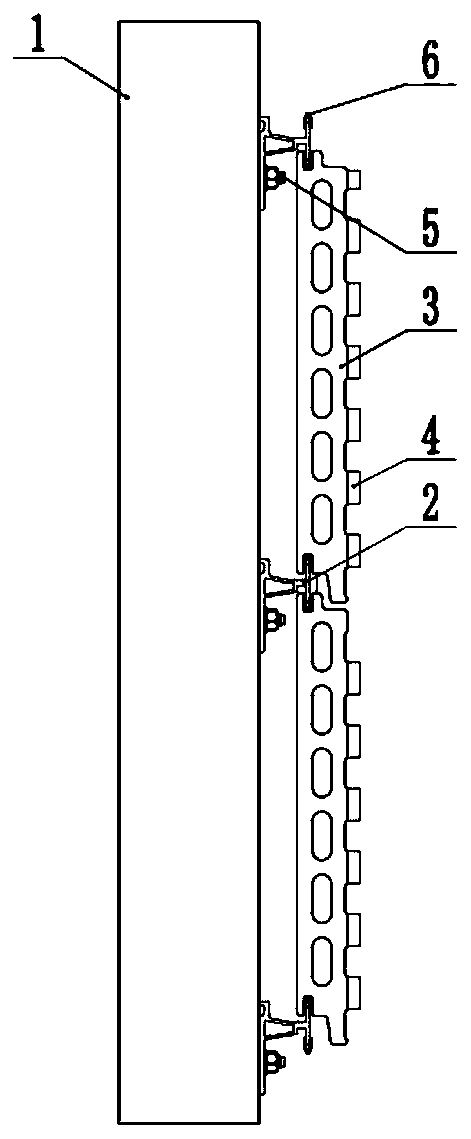

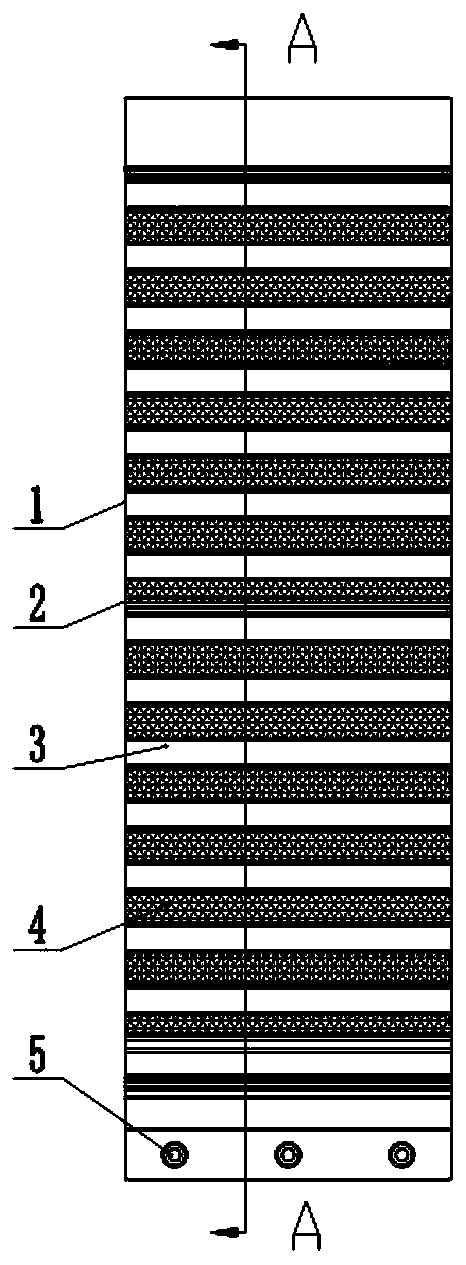

[0042] A kind of civil building prefabricated composite wall body, such as Figure 1-5 As shown, it includes a wall body 1 and several assemblies installed on one side of the outer wall of the wall body 1 . Among them, the fixed part 3 is used to fix the power generation part 4, the connecting part 2 is used to connect the fixed part 3 and the wall body 1, and the power generation part 4 is used to absorb and store the power generation equipment; the fixed parts 1 are vertically arranged in a single row on the wall body 1- side, and the adjacent fixing part 3 is fixed in series on the wall body 1 through the connecting part 2; one end of the connecting part 2 is fixedly connected with the wall body 1, and the other end of the connecting part 2 is fixedly connected with the fixing part 3; the shockproof part 6 is provided At the joint between the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com