Module intelligent anti-seismic insulation integrated structure house

An assembly structure and integrated technology, which is applied in the direction of building components, building structures, and building materials processing, to achieve the effects of easy quality control, fast installation, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

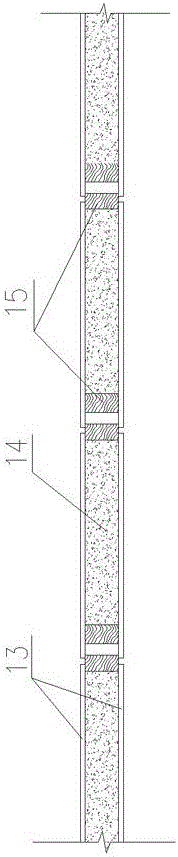

[0049] Embodiment 1. The board prepared in this embodiment has better thermal insulation performance and is mainly used as an exterior wall board.

[0050] In the first step, the unbroken whole dry (moisture content 15%~20%) plant straw (such as rice straw, wheat straw, grass straw and other long strips of plant straw) is stamped and formed on the equipment, And during the stamping process, the plant straw is treated with high temperature (180~200°C). The purpose of high temperature treatment is to kill insect eggs and bacteria in the straw, and further reduce the water content of the straw; stamping to a density of 200~350 kg / m 3 . The high temperature treatment can also dissolve the bonding components in the plant stalks, which can be used for bonding between the stalks. No adhesive is added during the preparation process to ensure that the finished board does not generate air pollution. Then wrap the stamped straw with one-way air-permeable paper (cloth) on the equipmen...

Embodiment 2

[0056] Embodiment 2, the board prepared in this embodiment is mainly used as an interior wall board.

[0057] In the first step, the unbroken whole dry (moisture content 15%~20%) plant straw (such as rice straw, wheat straw, grass straw and other long strips of plant straw) is stamped and formed on the equipment, And during the stamping process, the plant straw is treated with high temperature (180~200°C). The purpose of high temperature treatment is to kill insect eggs, bacteria, etc. in the straw, and further reduce the water content of the straw; stamping to a density of 200~350kkg / m 3 . The high temperature treatment can also dissolve the bonding components in the plant stalks, which can be used for bonding between the stalks. No adhesive is added during the preparation process to ensure that the finished board does not generate air pollution. Then wrap the stamped straw with one-way air-permeable paper (cloth) on the equipment, and cut it according to the designed size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com