Intelligent induction discoloring fabric used for household textile products and preparation method thereof

An intelligent and fabric technology, which is applied in the field of home textile fabrics, can solve the problems of not being easy to observe whether it is clean, and achieve the effect of low price, simple preparation process and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

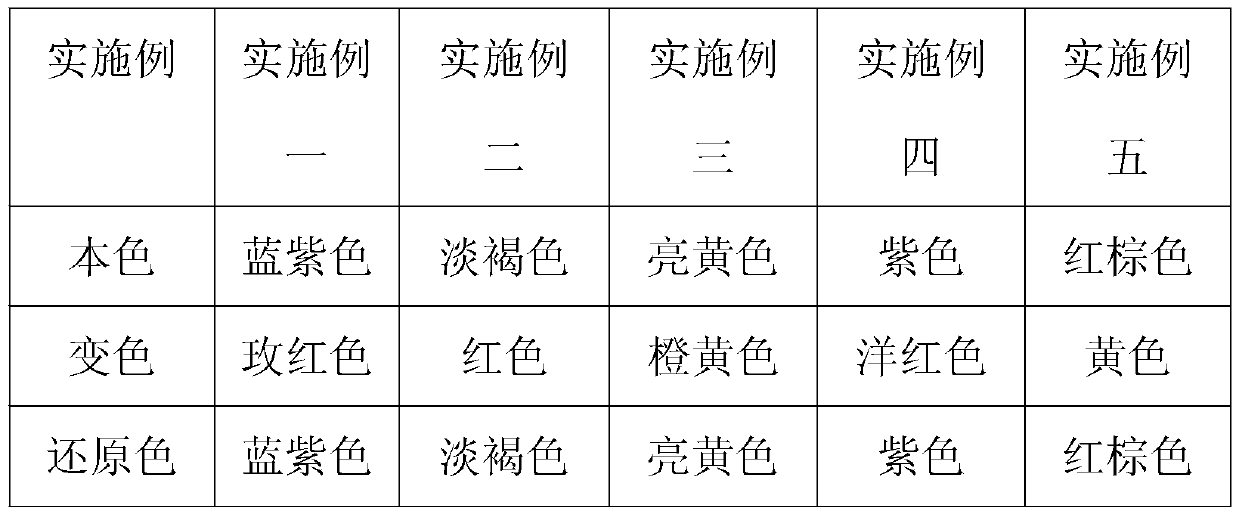

Embodiment 1

[0024] An intelligent sensing color-changing fabric for home textile products is produced by dyeing polyester-cotton blended fabrics with intelligent sensing dyes. The intelligent sensing dyes include the following raw materials in parts by weight: intelligent sensing pigment 3, printing adhesive 4.5, water 92.5, intelligent sensing dye The sensory pigment is litmus.

[0025] In this embodiment, the polyester-cotton blended fabric is woven from 93 parts by weight of cotton fibers and 7 parts by weight of polyester fibers, and the printing adhesive is HC-1040F.

[0026] A method for preparing an intelligent sensor color-changing fabric for home textile products, comprising the following steps:

[0027] S1. Mix 3 parts by weight of smart sensory pigment, 4.5 parts by weight of printing adhesive and 92.5 parts by weight of water to make smart sensory dyes for later use;

[0028] S2, singeing the polyester-cotton blended fabric to remove the fluff on the cloth surface;

[0029] ...

Embodiment 2

[0035] An intelligent sensing color-changing fabric for home textile products is produced by dyeing polyester-cotton blended fabrics with intelligent sensing dyes. The intelligent sensing dyes include the following raw materials in parts by weight: intelligent sensing pigment 3.5, printing adhesive 4.5, water 92, intelligent sensing dye The sensory pigment is red rice red.

[0036] In this embodiment, the polyester-cotton blended fabric is woven from 93 parts by weight of cotton fibers and 7 parts by weight of polyester fibers, and the printing adhesive is HC-1040F.

[0037] A method for preparing an intelligent sensor color-changing fabric for home textile products, comprising the following steps:

[0038] S1. Mix 3.5 parts by weight of smart sensory pigment, 4.5 parts by weight of printing adhesive and 92 parts by weight of water to make smart sensory dyes for later use;

[0039] S2, singeing the polyester-cotton blended fabric to remove the fluff on the cloth surface;

[...

Embodiment 3

[0046] An intelligent sensing color-changing fabric for home textile products is produced by dyeing polyester-cotton blended fabrics with intelligent sensing dyes. The intelligent sensing dyes include the following raw materials in parts by weight: intelligent sensing pigment 3.5, printing adhesive 4, water 92.5, intelligent sensing dye The sensory pigment is gardenia yellow pigment.

[0047] In this embodiment, the polyester-cotton blended fabric is woven from 93 parts by weight of cotton fibers and 7 parts by weight of polyester fibers, and the printing adhesive is HC-1040F.

[0048] A method for preparing an intelligent sensor color-changing fabric for home textile products, comprising the following steps:

[0049] S1. Mix 3.5 parts by weight of smart sensory pigment, 4 parts by weight of printing adhesive and 92.5 parts by weight of water to make smart sensory dyes for later use;

[0050] S2, singeing the polyester-cotton blended fabric to remove the fluff on the cloth su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com