Production technology of labyrinth-crepe-appearance pure-cotton yarn-dyed fabric

A production process, pure cotton technology, applied in the processing of textile materials, weaving, fabrics, etc., can solve the problems of poor shape stability, large dimensional change rate, etc., and achieve the effect of fluffy fabric, three-dimensional appearance, and full hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

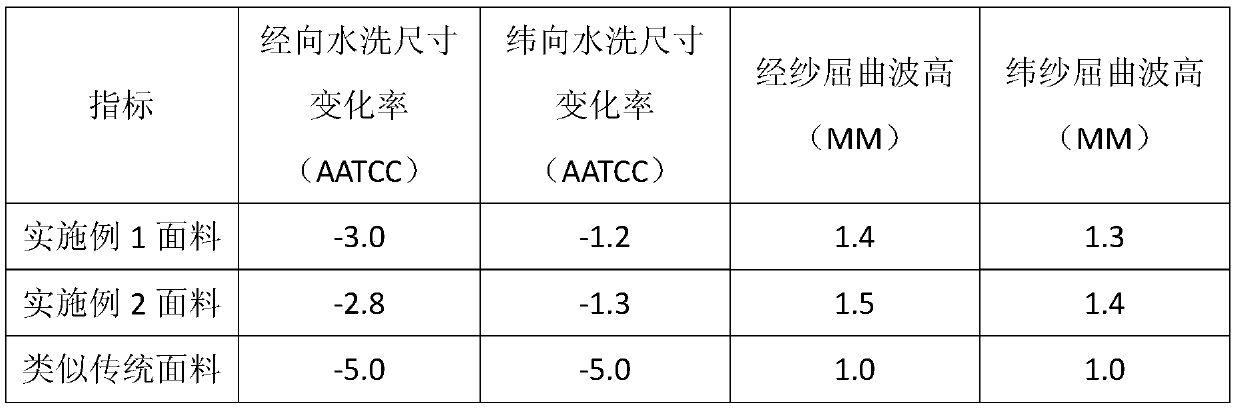

Examples

Embodiment 1

[0015] 60-count labyrinth crepe-appearance pure cotton yarn-dyed fabric, the technological process is: pattern weave specification design → warp and weft yarn processing → weaving → finishing. in:

[0016] In the pattern design process, the warp yarn is made of pure cotton bleached and then twisted and twisted with a strong twist of 60 lbs. The initial twist is 26 twists / inch, and the twist is increased by 20 twists / inch in the secondary twisting process. The weft yarn adopts a twisted strong twisted yarn with a twist of 37 twists / inch. The weave is plain weave, the warp density is 100 threads / inch, and the weft density is 100 threads / inch.

[0017] The process flow of warp yarn treatment is as follows: loose winding → cheese bleaching → rewinding → secondary twisting → steamed yarn fixing twist → warping → sizing → weaving, among which, loose winding, cheese bleaching, rewinding , warping, and sizing process parameters are the same as the conventional process; the steamed y...

Embodiment 2

[0024] 40-count labyrinth crepe-appearance pure cotton yarn-dyed fabric, the technological process is: pattern weave specification design → warp and weft yarn processing → weaving → finishing. in:

[0025] In the design process of pattern weave specifications, the warp yarn is made of pure cotton whitened and then twisted and strongly twisted yarn of 40 lbs. The initial twist is 24 twists / inch, and the twist is increased by 16 twists / inch in the secondary twisting process. The weft yarn adopts a strong twisted yarn twisted once, and the twist is 35 twists / inch. The weave is plain weave, the warp density is 80 threads / inch, and the weft density is 80 threads / inch.

[0026] The process flow of warp yarn treatment is as follows: loose winding → cheese bleaching → rewinding → secondary twisting → steamed yarn fixing twist → warping → sizing → weaving, among which, loose winding, cheese bleaching, rewinding , warping, and sizing process parameters are the same as the conventional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com