Biomass carbonization method and soil conditioner prepared by method

A biomass charcoal and carbonization technology, applied in chemical instruments and methods, biofuels, soil conditioning materials, etc., can solve the problems of high energy consumption of biomass carbonization, high liquid-phase straw oil yield, and unstable straw oil, etc. Achieve the effect of improving fertilizer utilization, reducing nutrient loss and improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

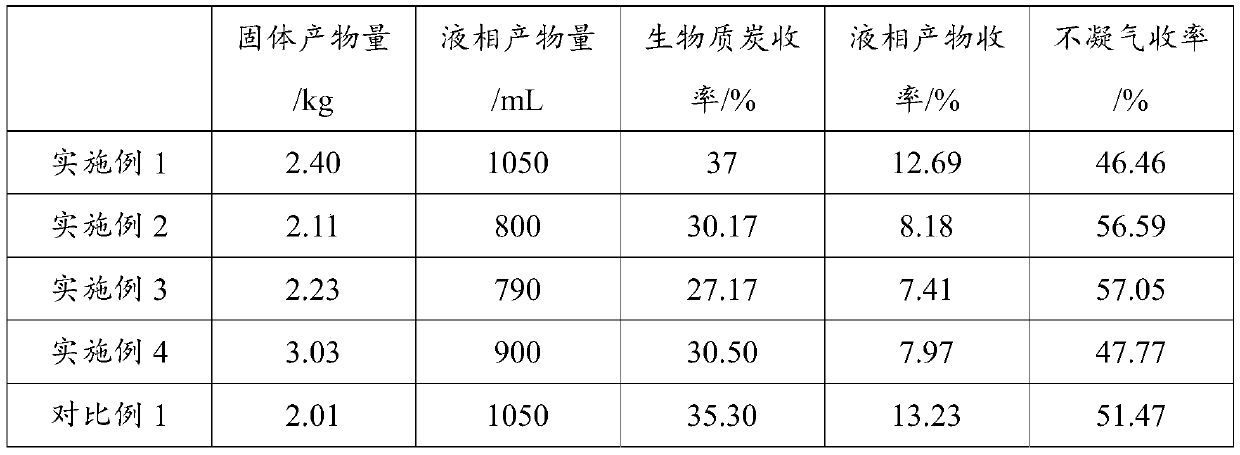

Embodiment 1

[0022] This embodiment provides a method for carbonizing biomass, comprising the steps of:

[0023] (1) Take by weighing 5.82kg of rice husk particles and 0.18kg of attapulgite respectively, mix uniformly, and dry to obtain mixture particles;

[0024] (2) Put the above-mentioned mixture particles in a carbonization furnace, feed nitrogen gas until the oxygen content in the carbonization furnace is no more than 3%, heat to 350° C., and carbonize the mixture particles at this temperature for 1.0 h to obtain solid matter and straw gas;

[0025] (3) Condensing the above-mentioned straw gas to obtain a liquid phase product and non-condensable gas, and the liquid phase product includes straw oil and wood vinegar.

Embodiment 2

[0027] This embodiment provides a method for carbonizing biomass, comprising the steps of:

[0028] (1) Take by weighing 5.7kg rice husk debris and 0.3kg attapulgite respectively, mix uniformly, and dry to obtain mixture granules;

[0029] (2) Put the above-mentioned mixture particles in a carbonization furnace, feed nitrogen gas until the oxygen content in the carbonization furnace is not more than 3%, heat to 450° C., and carbonize the mixture particles at this temperature for 1.0 h to obtain solid matter and straw gas;

[0030] (3) Condensing the above-mentioned straw gas to obtain a liquid phase product and non-condensable gas, and the liquid phase product includes straw oil and wood vinegar.

Embodiment 3

[0032] This embodiment provides a method for carbonizing biomass, comprising the steps of:

[0033] (1) Take by weighing 5.4kg rice husk particles and 0.6kg attapulgite respectively, mix uniformly, and dry to obtain mixture particles;

[0034] (2) Put the above-mentioned mixture particles in a carbonization furnace, feed nitrogen gas until the oxygen content in the carbonization furnace is no more than 3%, heat to 430° C., and carbonize the mixture particles at this temperature for 1.0 h to obtain solid matter and straw gas;

[0035] (3) Condensing the above-mentioned straw gas to obtain a liquid phase product and non-condensable gas, and the liquid phase product includes straw oil and wood vinegar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com