Numerical control automatic winding equipment for door and window brush seal

A technology of sealing tops and automatic tape winding, which is applied in the direction of winding strips, measuring devices, instruments, etc., can solve the problems of staggered hairs and whiskers, weakened sealing effect, and poor winding quality, so as to reduce the staggered hairs and whiskers , reduce shaking and offset, improve the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

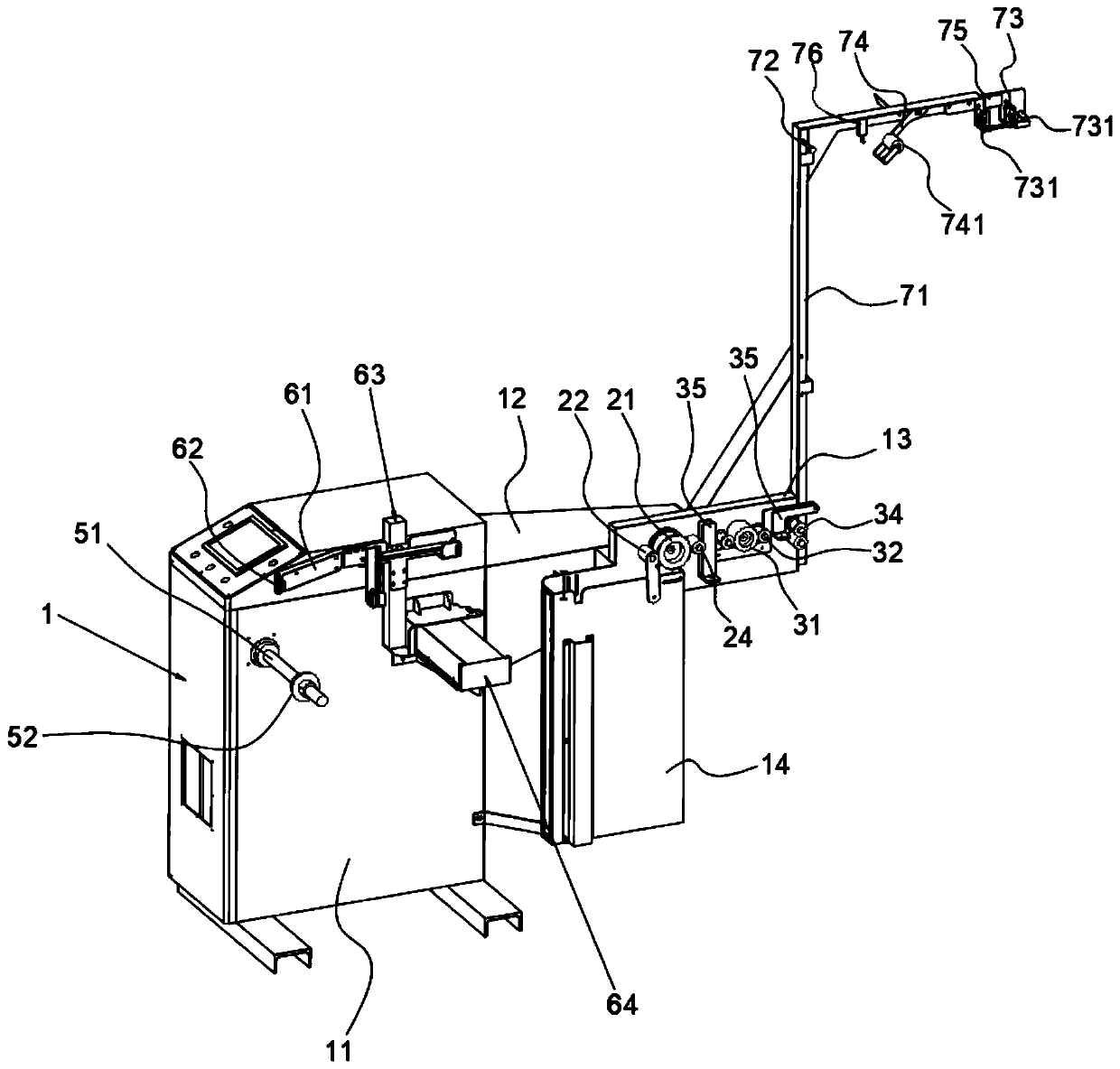

[0031] Such as figure 1 As shown, the door and window sealing wool top CNC automatic tape winding equipment includes a control cabinet 1, a feeding device for providing power for wool top conveying, a meter counting device for measuring the length of wool top conveying, a laser detection device for detecting the feeding state of wool tops, and It is used to adjust the whole material device for the top discharge, and the winding device for winding the top; specifically, the feeding device provides the power for the top transmission, and the top transportation passes through the meter counting device, the feeding device, the laser detection device, and the whole material in turn. device, and finally through the winding device for tape finishing and recycling.

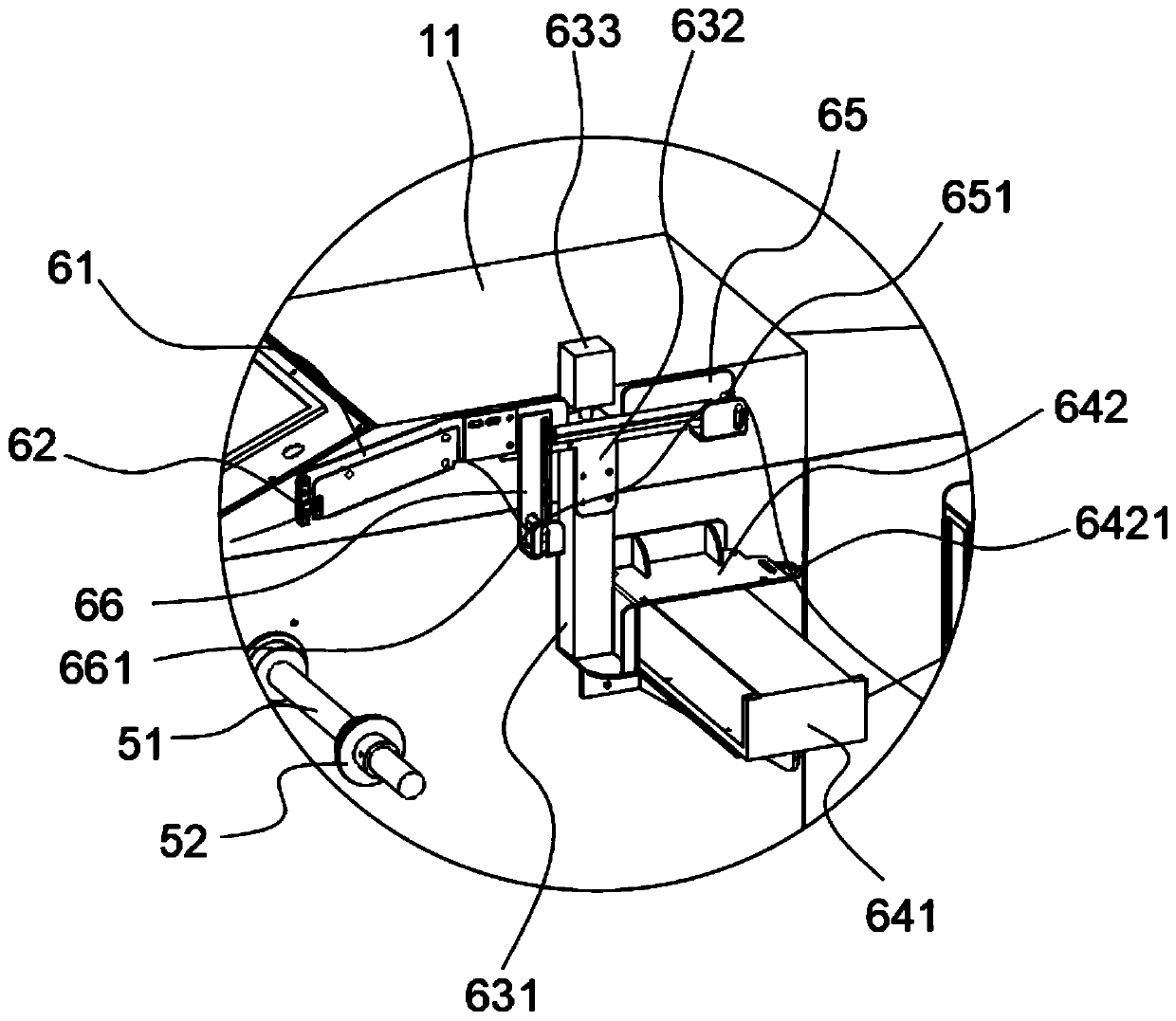

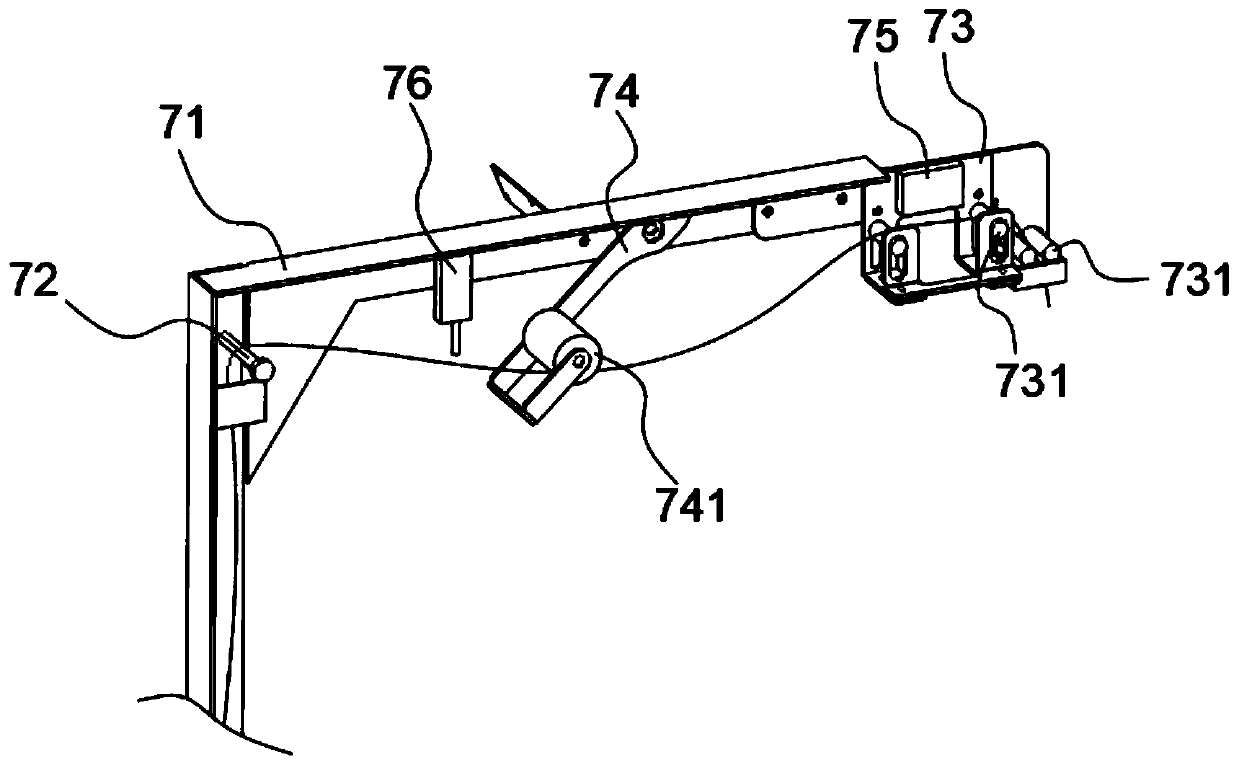

[0032] Such as figure 1 as well as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com