Forest-fruit branch extruding, slicing and smashing machine

A pulverizer and fruit branch technology, applied in the field of agricultural machinery, can solve the problems that the branches cannot be effectively sliced and pulverized, the pulverized raw materials are not completely pulverized, and the effective contact between the fermentation bacteria and the pulverized branches is affected, and the effect of improving the utilization rate and speeding up the processing efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific examples are given below.

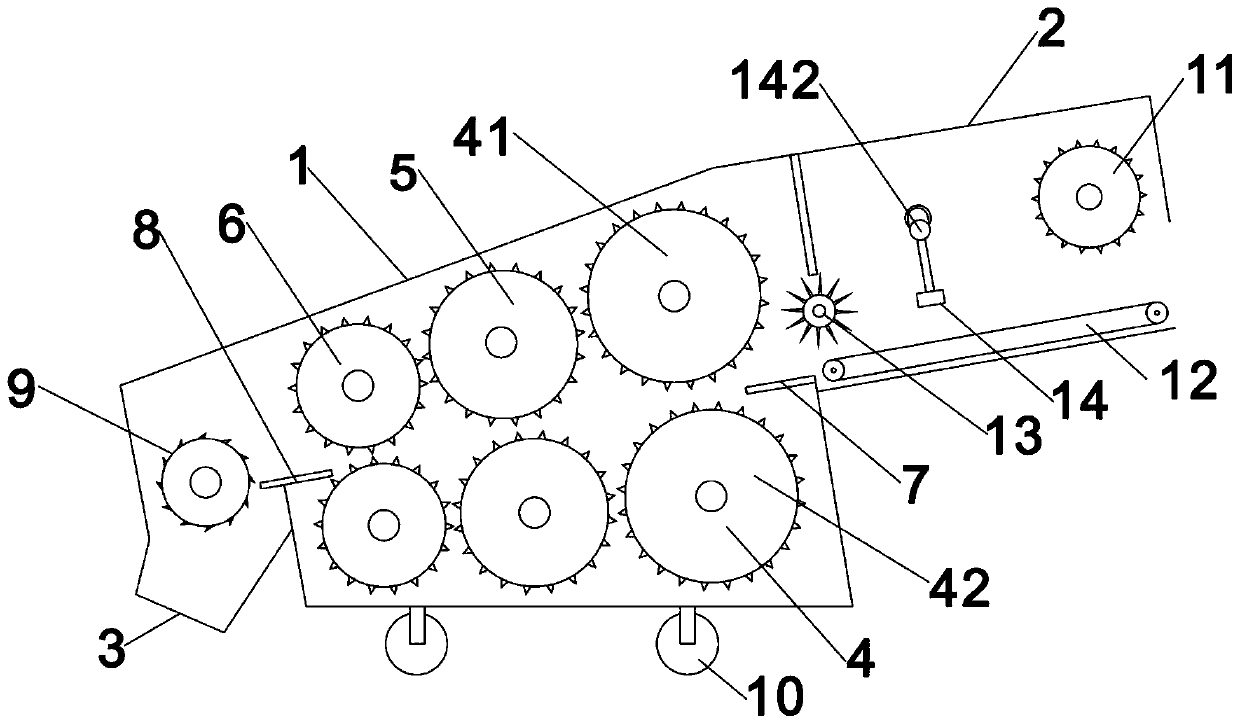

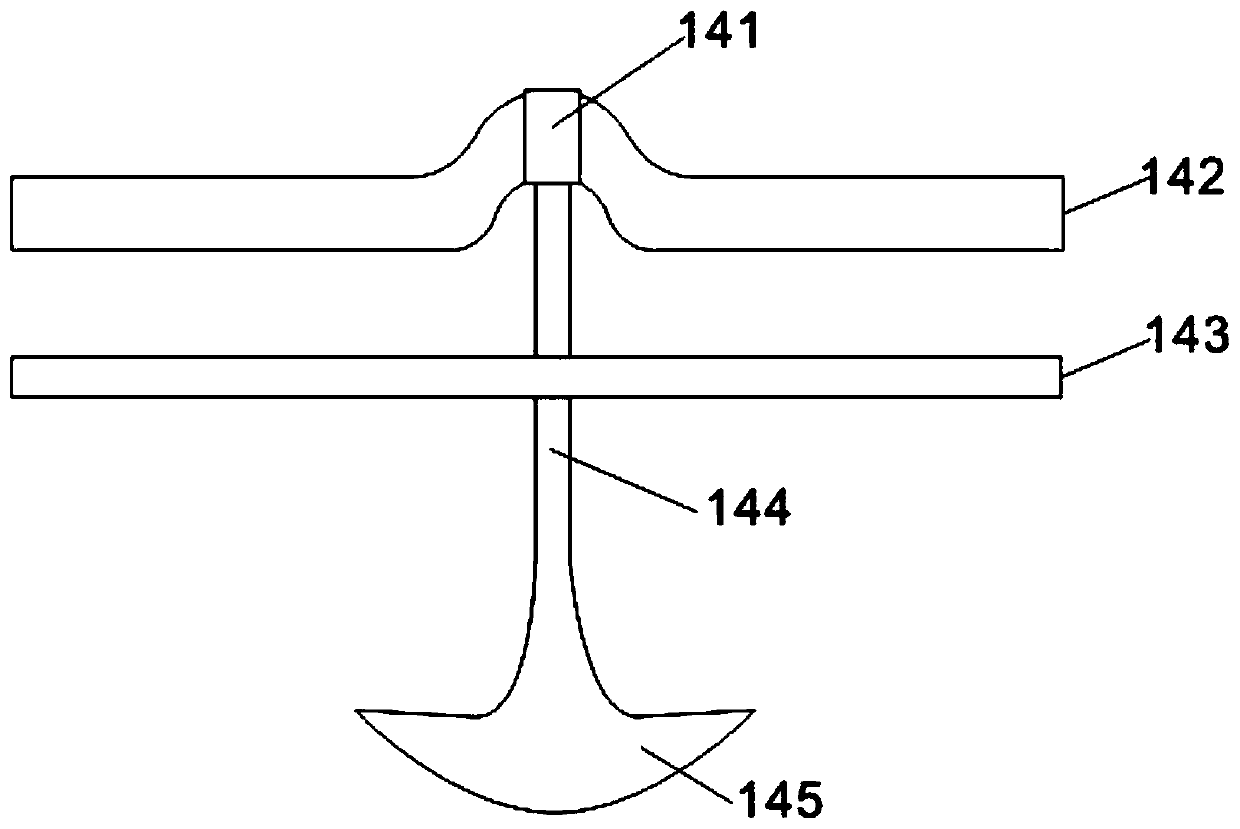

[0022] Such as figure 1 As shown, a forest fruit branch extrusion slicer comprises a shell 1, and the first-stage roller shaft group 4 with a rolling gap is arranged inside the shell 1, and the roller shaft of the first-stage roller shaft group 4 is provided with sharp points on the circumference. Thorn, the primary roller shaft group 4 is connected with the drive assembly that drives the primary roller shaft group 4 to work; wherein the primary roller shaft group 4 includes the first roller shaft 41 and the second roller shaft 42, the first roller shaft 41 and the second roller shaft group The two roller shafts 42 are connected in the housing 1 by bearings, the first roller shaft 41 and the second roller shaft 42 have the same size and structure and are parallel to each other, and the two ends of the first roller shaft 41 and the second roller shaft 42 extend out of the housing 1, the two ends of the first roller shaft 41 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com