HIFU sound field detection system based on finite element model method

A detection system and finite element technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, using electromagnetic means, etc., can solve problems such as single power index, unsuitable multi-parameter measurement, and staying in the stage of large-scale laboratory testing. To achieve the effect of avoiding the impact of accuracy and the integrity of the measured data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

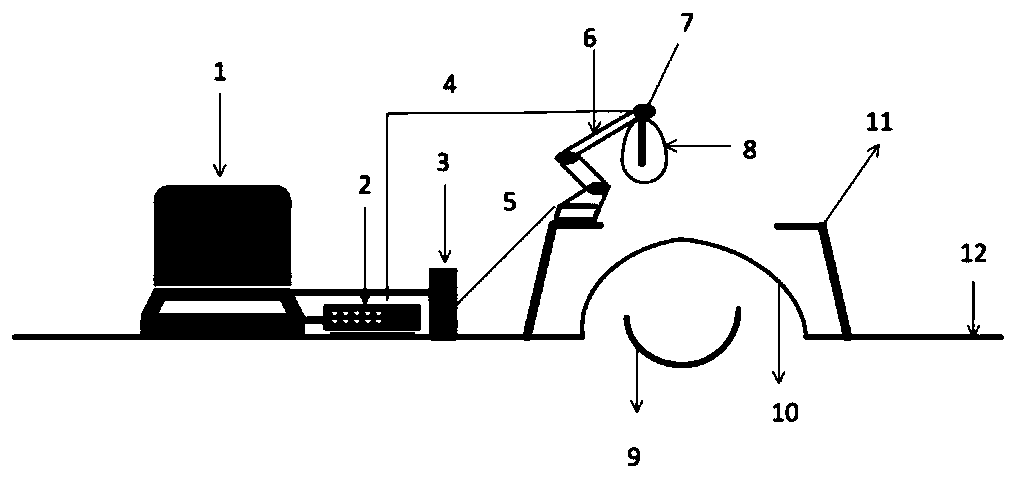

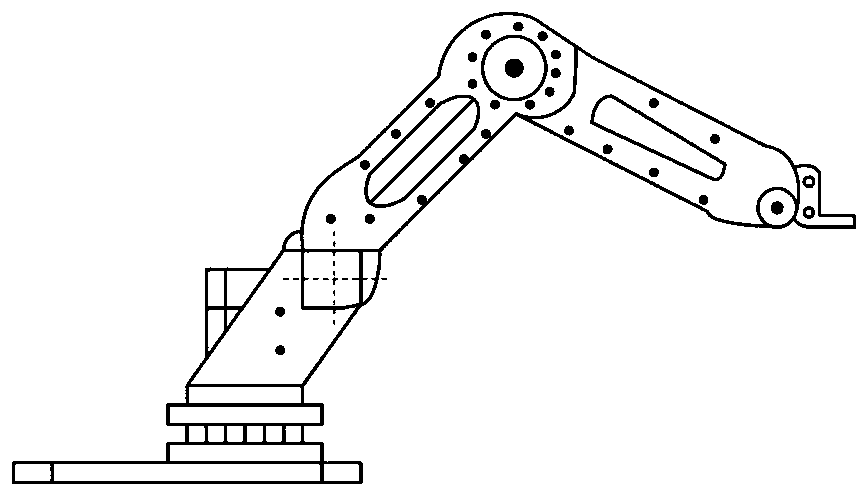

[0026] The practical invention is based on the finite model method, by establishing a model, analyzing the characteristics of the sound field of the transducer, and realizing the measurement of the sound field by controlling the mechanical arm to scan the three-dimensional space at the focal point of the high-intensity focused sound field. Fix the hydrophone fixture on the manipulator of the mechanical arm, fix the measuring hydrophone on the fixture, wrap the hydrophone with a sound-transmitting water bag and seal it with a hoop, the purpose is to prevent degassing in the sound-transmitting water bag Water leaks. Control the mechanical arm to couple the sound-transmitting water bladder with the water bladder that comes with the HIFU. The material of the sound-transmitting water bladder is selected to be consistent with the density of the water bladder that comes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com