Node deviation measuring instrument, manufacturing method thereof and method for measuring node deviation

A technology of deviation measurement and manufacturing method, which is applied in the field of shipbuilding and can solve the problems of poor generality of node deviation measuring instruments, inability of nodal deviation measuring instruments to measure the continuous state cross joints of intermediate plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

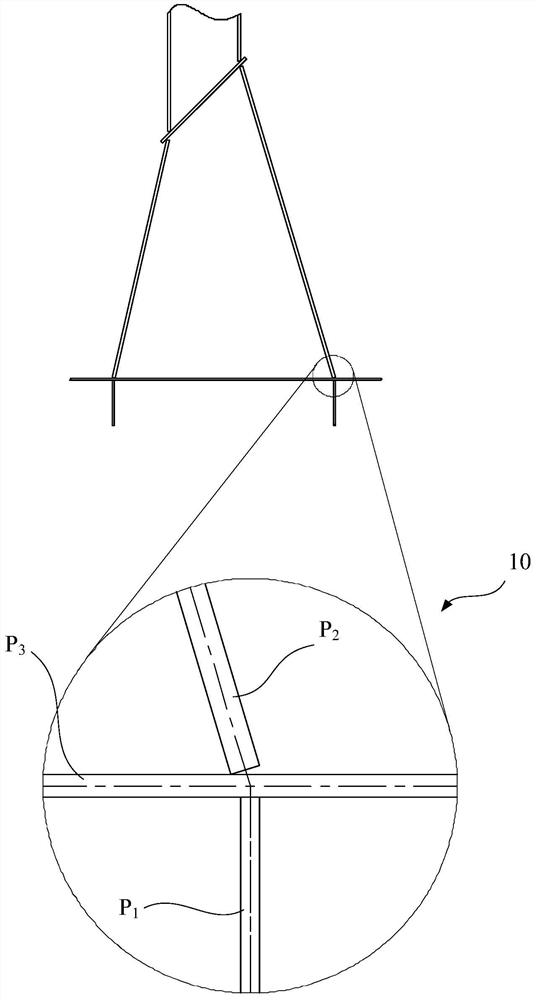

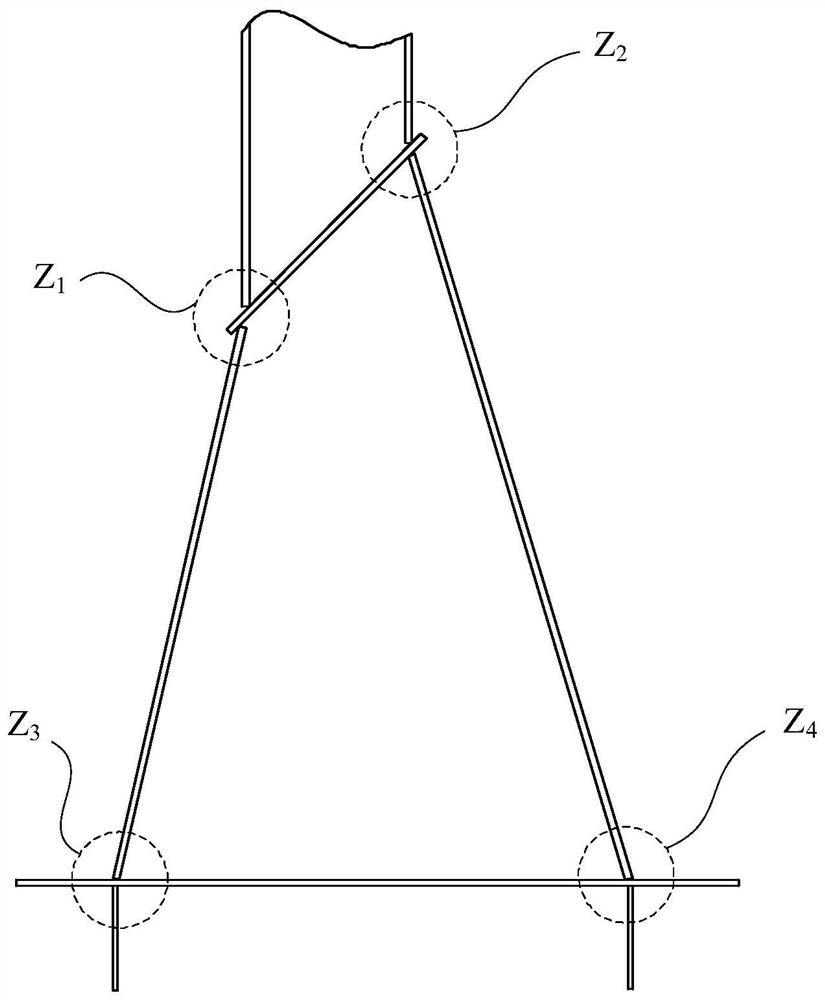

[0075] Such as image 3 As shown in the figure below, multiple cross joints (Z 1 ,Z 2 ,Z 3 ,Z 4 ) as an example, in this embodiment, first take the discontinuous cross joint Z of the middle plate (the third plate) 1 As research target.

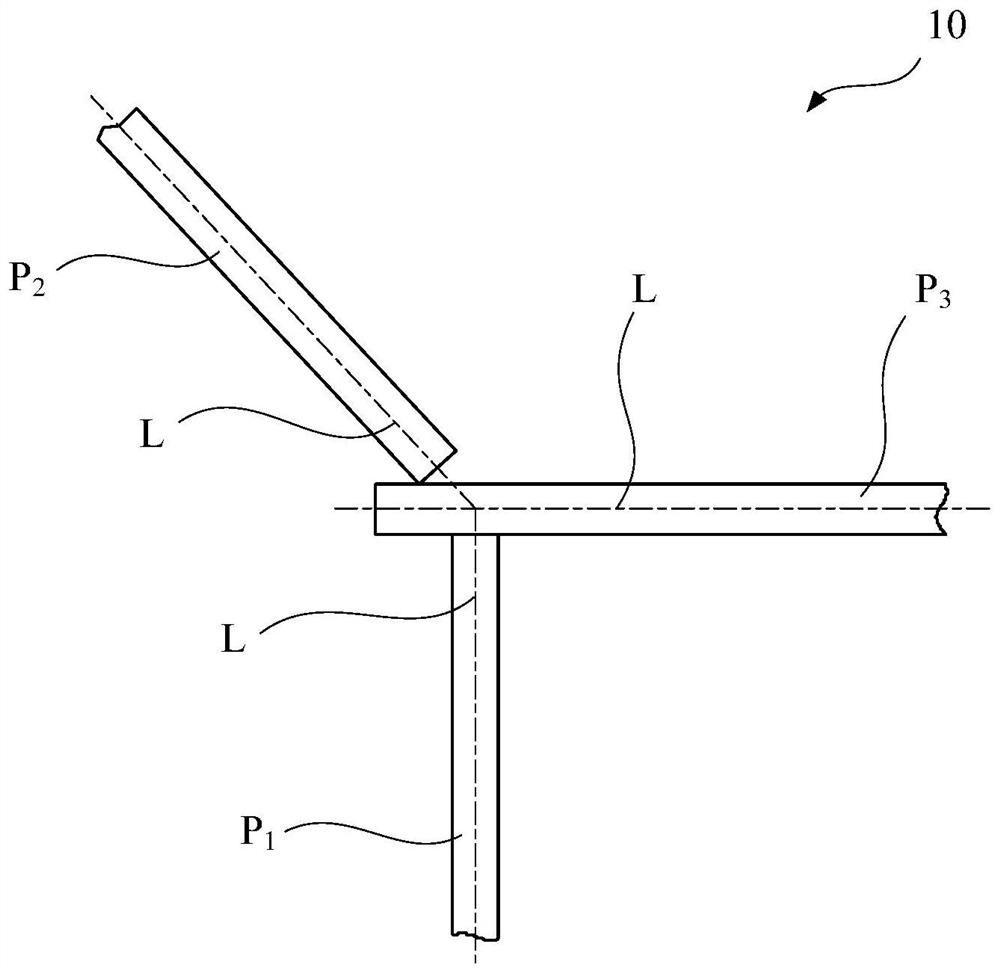

[0076] Step 1: For the convenience of observation, the node Z 1 Zoom in, and mark the centerlines of the first plate, the second plate and the third plate and the angle between them on the same side, that is, the angle β between the first plate and the third plate, and the angle between the second plate and the third plate angle θ, assuming that their center lines intersect at a point, see Figure 4 .

[0077] Step 2: Based on the state when the centerlines of the three boards intersect at one point, take their intersection point as the base point, and synchronize their centerlines as a whole along the centerline L of the first board 1 move down and make the centerline of the third plate L 3 coincides with its lower edge, see Figure...

Embodiment 2

[0095] for image 3 Cross fitting Z shown in 3 and Z 4 , since its third plate (middle plate) is continuous, it cannot be reused as Figure 8 The right edge of the first plate and the lower edge of the third plate of the illustrated cross joint hold the node deflection gauge 20 .

[0096] Such as Figure 10 As shown, in this embodiment, the cross joint Z 4 as an example. In this case, the upper surface of the third plate (middle plate) can be used for measurement. However, only the positioning condition of the upper surface of the third plate cannot completely position the node deviation measuring instrument 20, therefore, a positioning condition must also be found.

[0097] In this embodiment, for such a node, an initial reference point D can be drawn on the lower surface of the third plate with a certain set distance E from the intersection point of the surfaces of the first plate and the third plate 0 , the preferred range of the set distance E is between 50 mm and 2...

Embodiment 3

[0120] In the fore and aft cargo holds of bulk carriers, the key joints formed by the sloping plate of the hopper tank, the bracket at the lower end of the shell frame and the ribs in the hopper tank are more special, such as Figure 12 . The third plate (middle plate) of this critical cross joint is also continuous, but the centerline L of the first plate 1 and the centerline L of the second plate 2 coincides exactly, but with the centerline L of the third plate 3 All are skewed. For this critical cross joint, it is also necessary to use the reference line for deviation measurement.

[0121] Make the nodal deviation measuring instrument 20 with datum point 22 earlier at this, its manufacturing method and embodiment 2 provide roughly the same:

[0122] First, assuming that the central planes of the three plates of the cross joint intersect on a line, a plane perpendicular to the line is used to cut the three plates of the cross joint, and the obtained section is used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com