Segment lining grouting system and method based on outer-embedding-type channel and expandable bag

A grouting system and externally embedded technology, applied in tunnel lining, wellbore lining, tunnel, etc., can solve the problem of unfavorable tunnel structure stability and environmental safety protection, unfavorable engineering investment control, and can not meet the effective three-dimensional annular space of shield tail gap. Filling and other problems can be achieved to meet the requirements of formation stability, reduce the amount of grout grouting, and save project investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

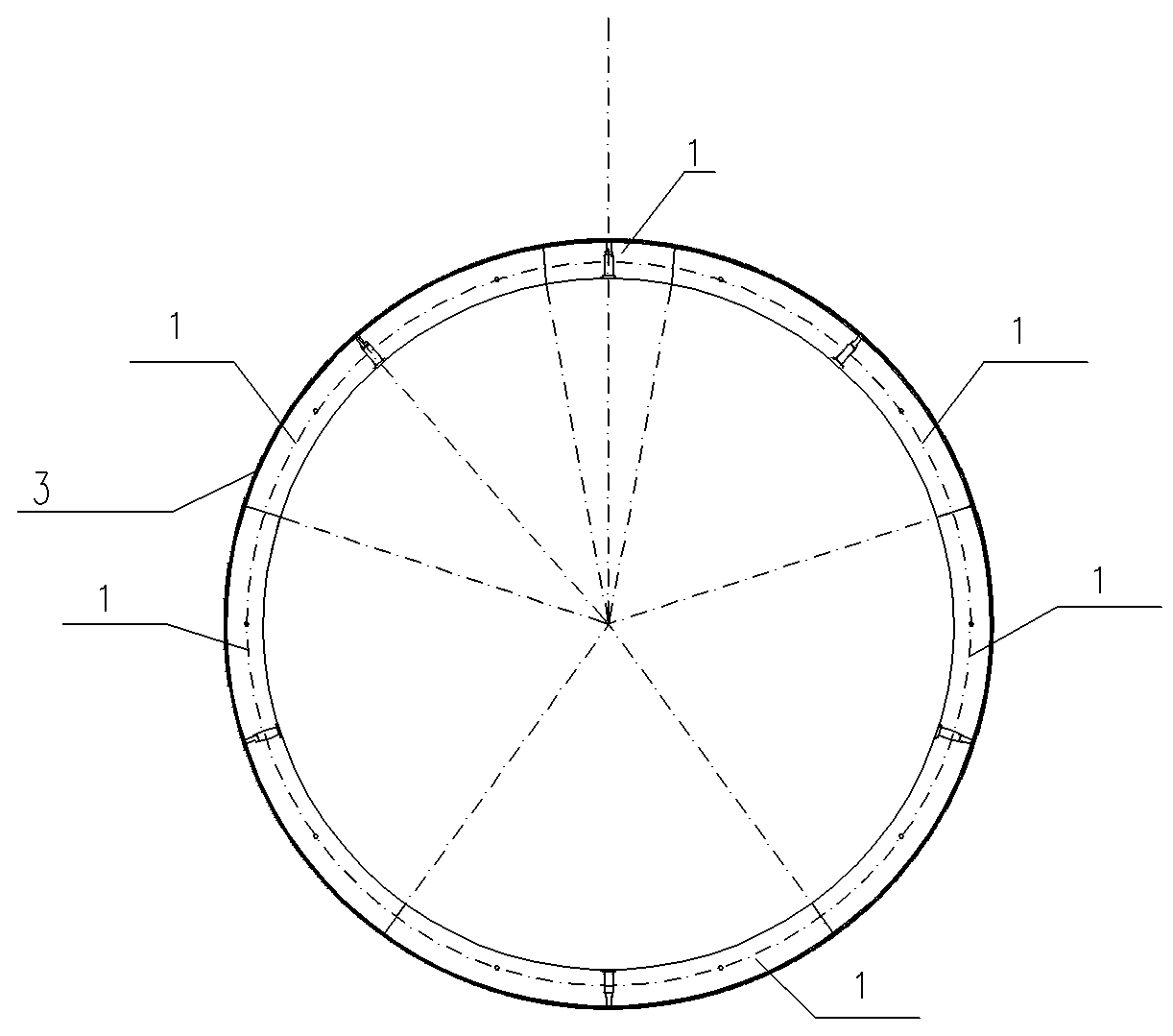

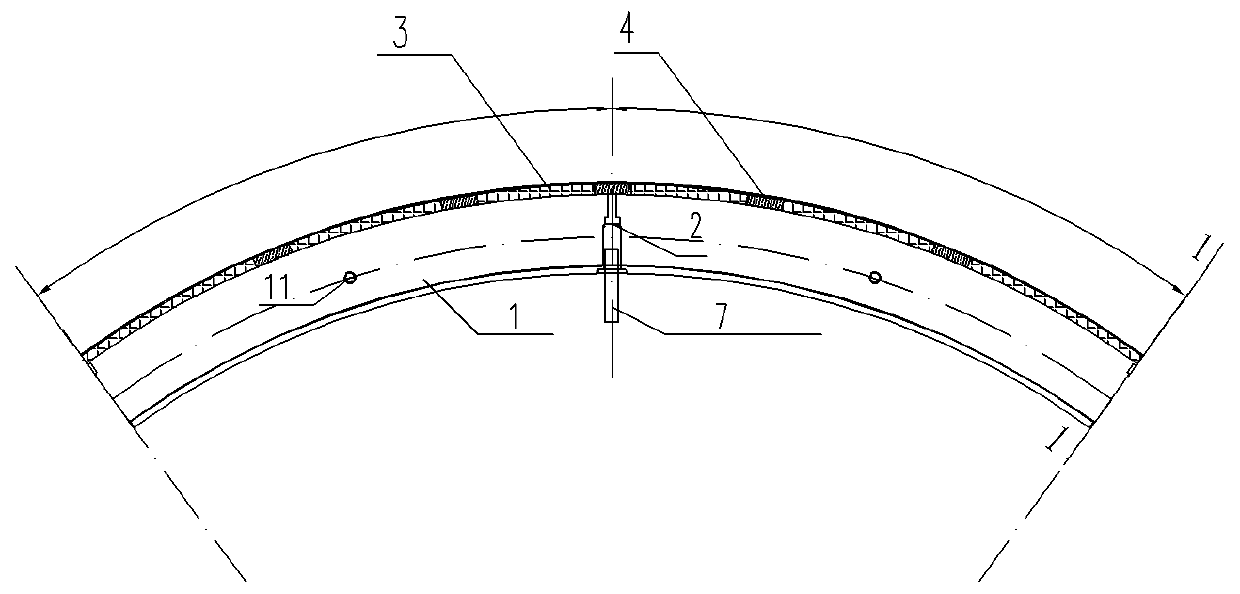

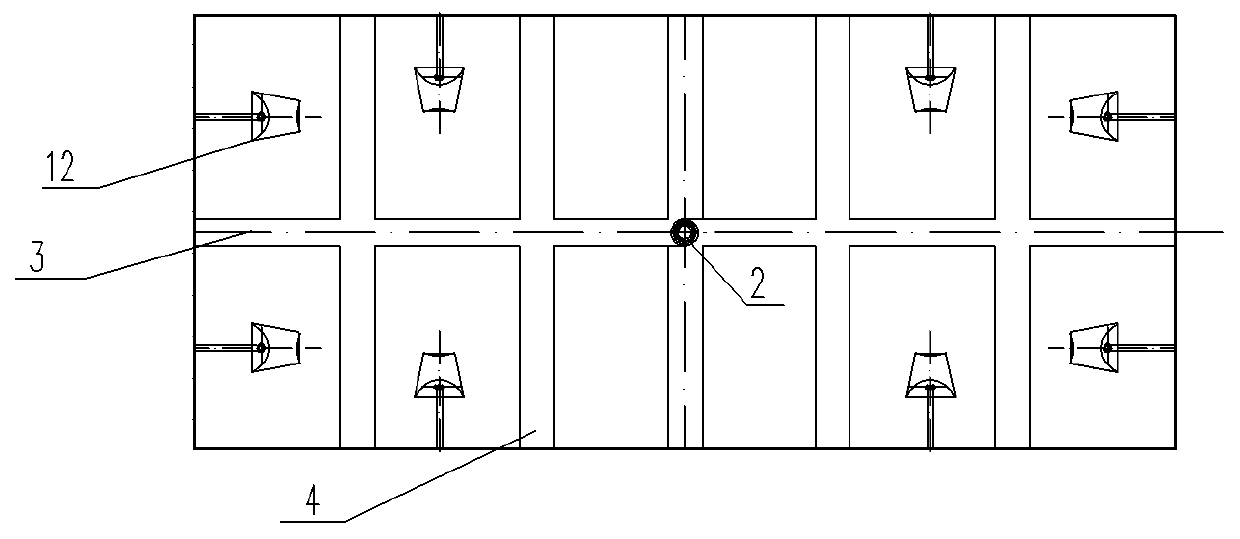

[0038] The invention relates to a segment lining grouting system based on an external channel and a stretchable bladder, which includes a tunnel structure composed of a segment lining 1, and a grouting hole serving as a hoisting hole is pre-embedded in the center of the segment lining 1 Hole 2, the outer arc surface of the segment lining 1 is provided with horizontal and vertical external embedded channels, the main channel 3 for slurry diffusion along the circumferential direction of the segment, and the secondary channel 4 for slurry diffusion along the longitudinal direction of the tunnel, the main channel 3 for slurry diffusion is connected with the injector The pulp holes 2 are connected. The segmental lining 1 of the tunnel structure includes the capping block, adjacent blocks on both sides of the capping block, and the rest of the standard blocks in the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com