Multi-stage liquid distributor

A technology of liquid distributor and distribution box, which is applied in fine chemical industry, petrochemical industry, coal chemical industry, and coking industry. It can solve the problems of uneven distribution, small opening ratio, and few liquid distribution points, so as to improve the efficiency of gas-liquid mass transfer. , Strong anti-clogging ability, uniform liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

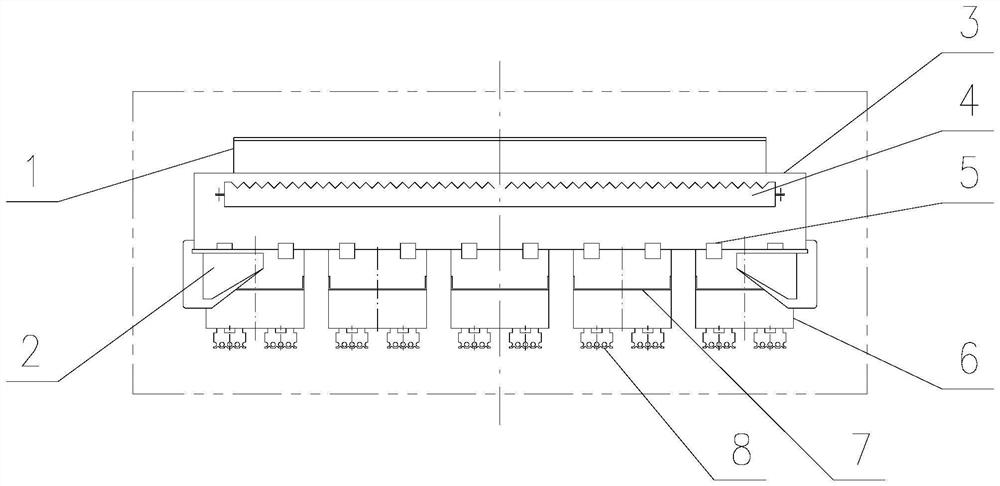

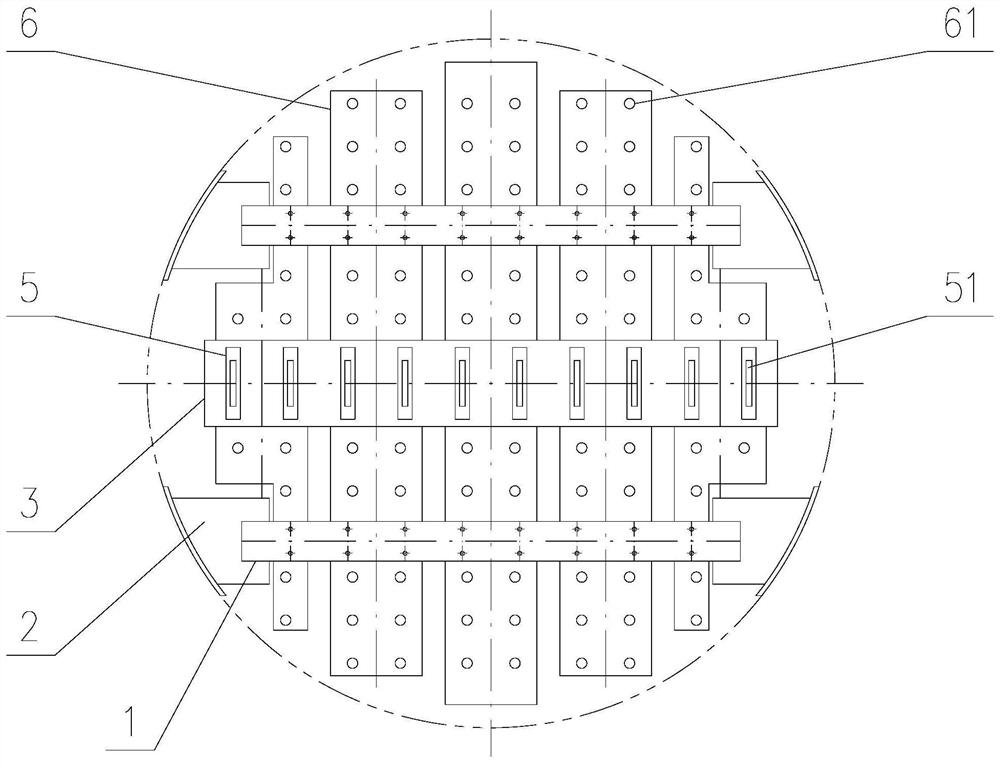

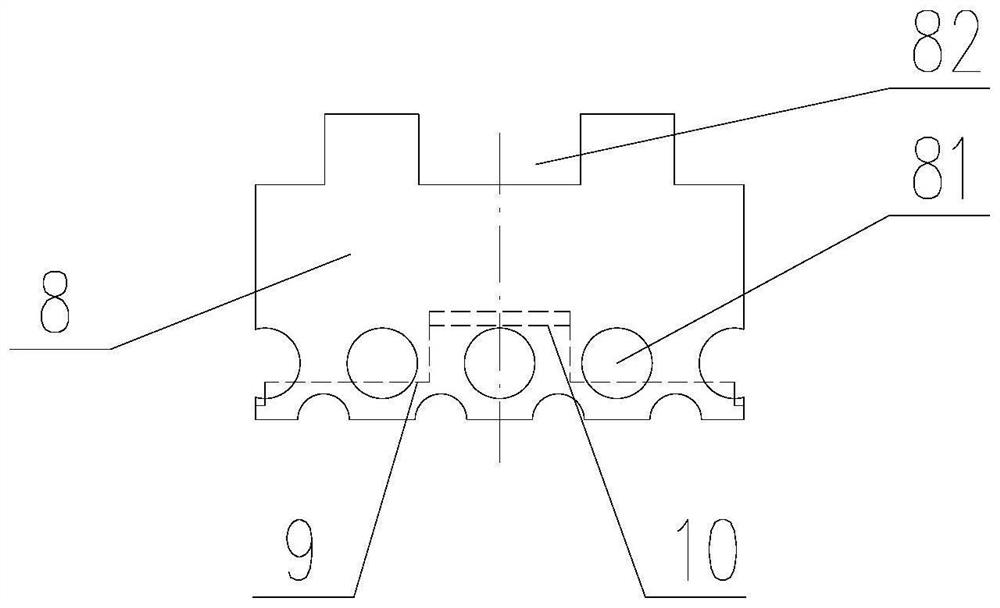

[0036] A multi-stage liquid distributor (distributor for short) is characterized in that, the distributor comprises a support beam 1, a support 2, a primary groove 3, a buffer groove 4, a distribution box 5, a secondary groove 6, a buffer plate 7 and assemblies;

[0037] The support 2 is welded and fixed on the inner side of the tower wall; the two ends of the support beam 1 are detachably fixed on their respective supports 2 through bolts and nuts, parallel to the horizontal plane (that is, the cross-section of the tower); along the cross-sectional direction of the tower , a number of secondary slots 6 are detachably mounted on the bottom of the support beam 1 through bolts and nuts;

[0038] Along the cross-sectional direction of the tower, at least one primary slot 3 is detachably fixed on the tops of all secondary slots 6 through bolts and nuts; each primary slot 3 is provided with a detachable buffer slot 4, located in the primary slot 3. The upper or middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com