Water-based paint composition and coating formed by water-based paint composition

A kind of technology of water-based paint and composition, applied in directions such as coating, can solve the problems such as formaldehyde purification efficiency cannot reach Class I formaldehyde purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0109] The preparation of the water-based coating composition of the present invention can be realized by any suitable mixing method known to those of ordinary skill in the art. For example, a waterborne coating composition can be prepared by adding the waterborne latex, filler and additives to a container, and then stirring the resulting mixture until homogeneous. Alternatively, the waterborne coating composition can be prepared by mixing some of the additional additives with the filler, and then adding the waterborne latex and the remainder of the additional additives to form a homogeneous mixture. Additional water can be added during preparation of the aqueous coating composition, if desired. Additional water should be added to the total weight of the aqueous latex.

[0110] The aqueous coating composition of the present invention can be applied by conventional methods known to those of ordinary skill in the art. For example, aqueous coating compositions can be applied by...

Embodiment 1-3

[0128] The aqueous coating compositions of Examples 1-3 were prepared as follows.

[0129] The amount listed in the following table 2, under the low-speed stirring of 350-450rpm, add deionized water and thickener Natrosol Plus 330, dispersant, wetting agent, defoamer, pH regulator to the stirrer, and stir 5-10 minutes, thus evenly. The filler is then added to the mixture and stirred at high speed at 800-1250 rpm for 20-30 minutes to form a homogeneous slurry. Finally, under medium-speed stirring at 500-700rpm, add defoamer, water-based latex, silane coupling agent, tank preservative, antifungal agent, film-forming aid, thickener TT935 and the remaining Partially deionized water until homogeneous, thereby forming an aqueous coating composition.

Embodiment 1

[0130] The water-based coating composition of embodiment 1 is used as interior wall primer; The water-based coating composition of embodiment 2 and 3 is used as interior wall finish paint.

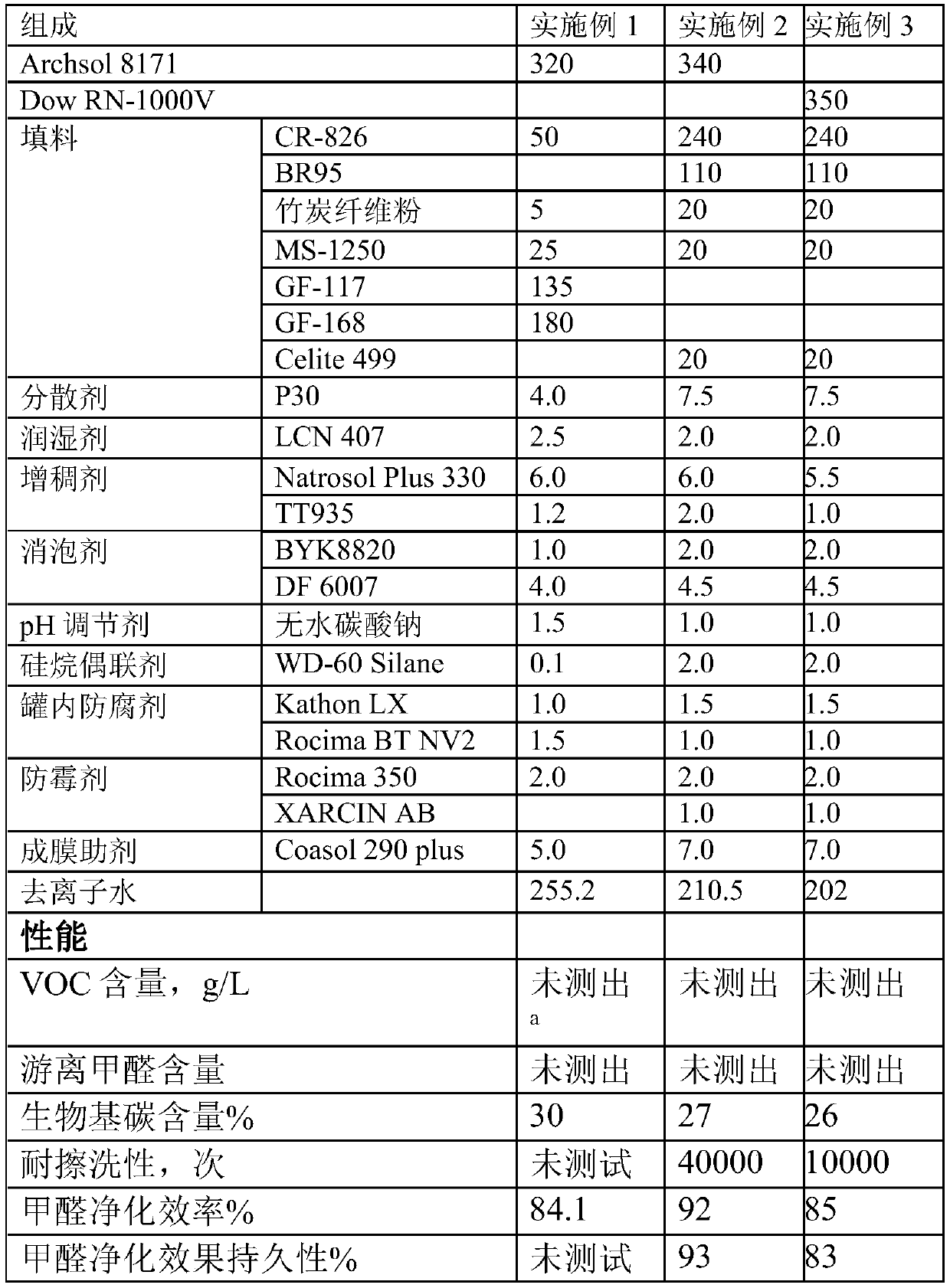

[0131] The consumption of each component in the water-based paint composition of Examples 1-3 and the properties of the water-based paint composition and the coating formed therefrom are listed in Table 2.

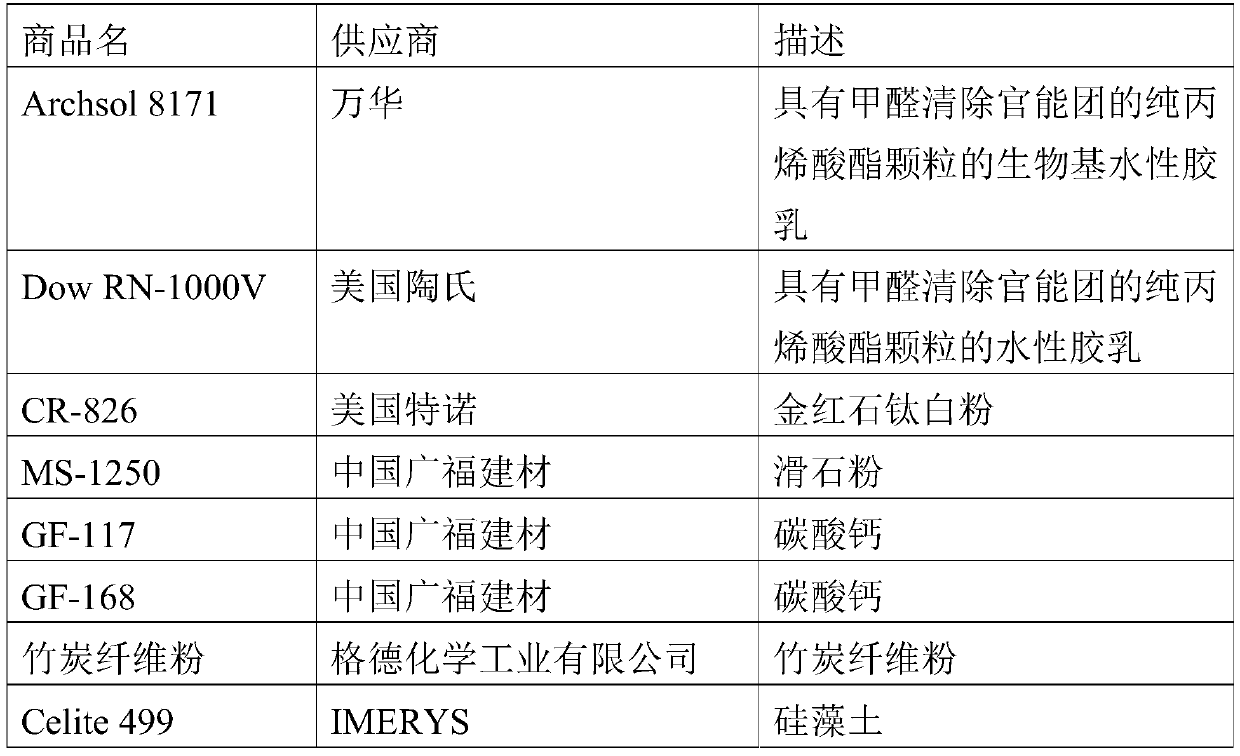

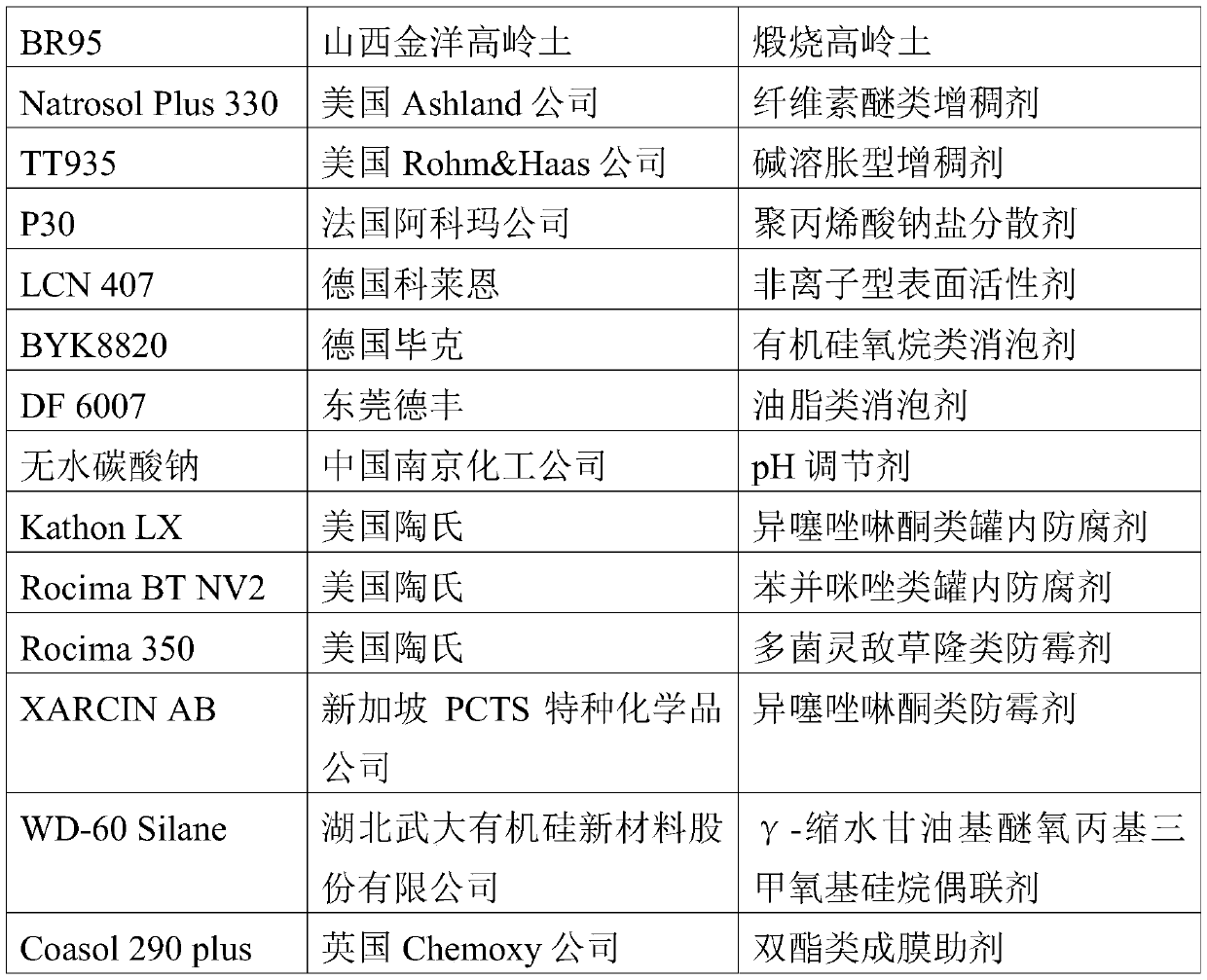

[0132] Table 2: Composition and properties of waterborne coating composition

[0133]

[0134] a Indicates that the VOC content is below the detection limit.

[0135] From the results in Table 2 above, it can be clearly seen that the bio-based carbon content of the water-based coating compositions of Examples 1-3 is at least 26% by weight, and can obtain the Biobased certification of the United States Department of Agriculture, and the raw materials for preparation are partially derived from renewable organisms. Basic resources, with the advantages of green environmental protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com