Medium-frequency power supply energy-saving control roll welding equipment and welding method thereof

An intermediate frequency power supply and rolling welding technology, which is applied in the direction of resistance welding equipment, welding equipment, roller electrode welding, etc., can solve the problem of how to save energy in welding equipment, and achieve the effects of stable current, low surface temperature and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

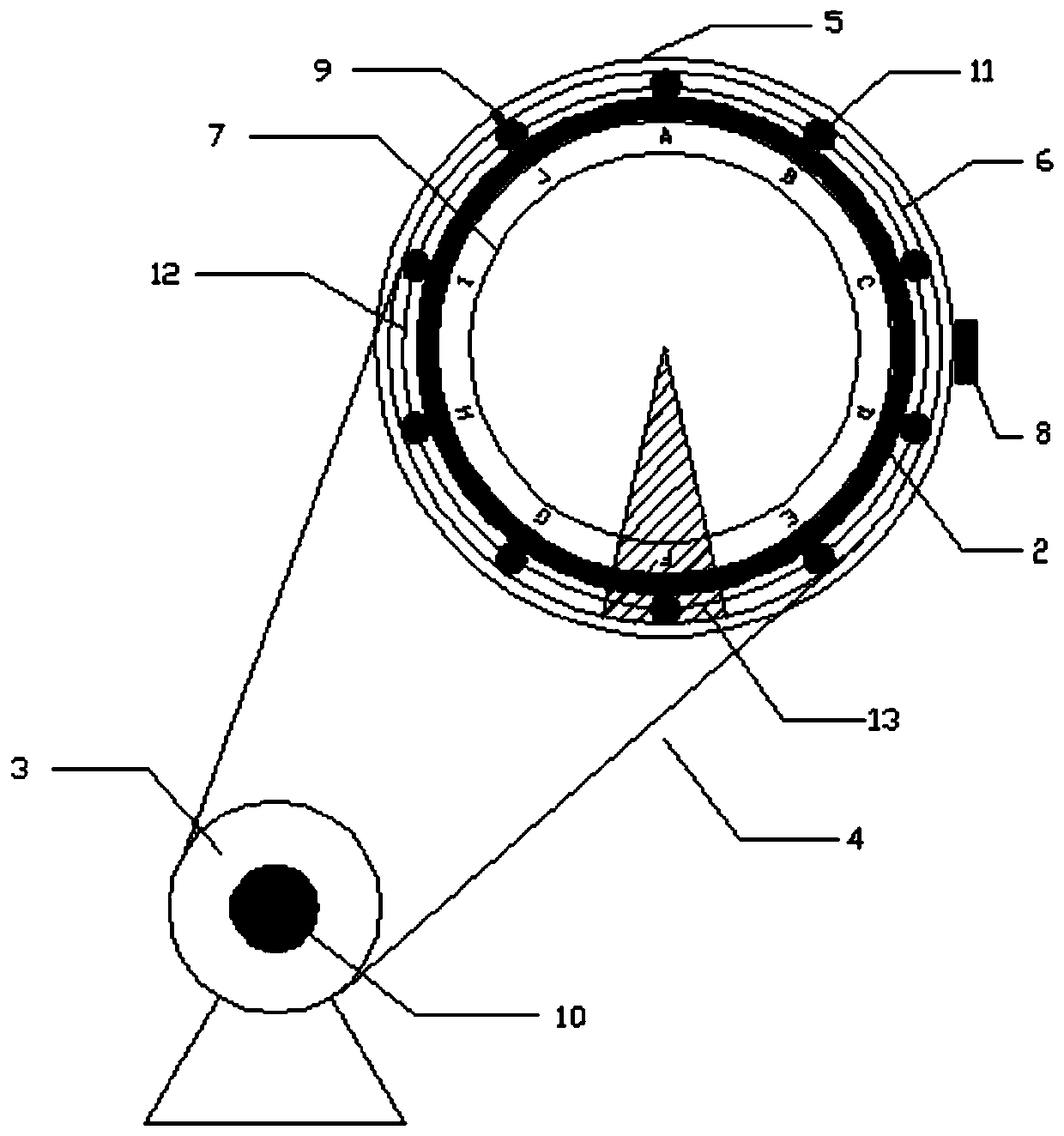

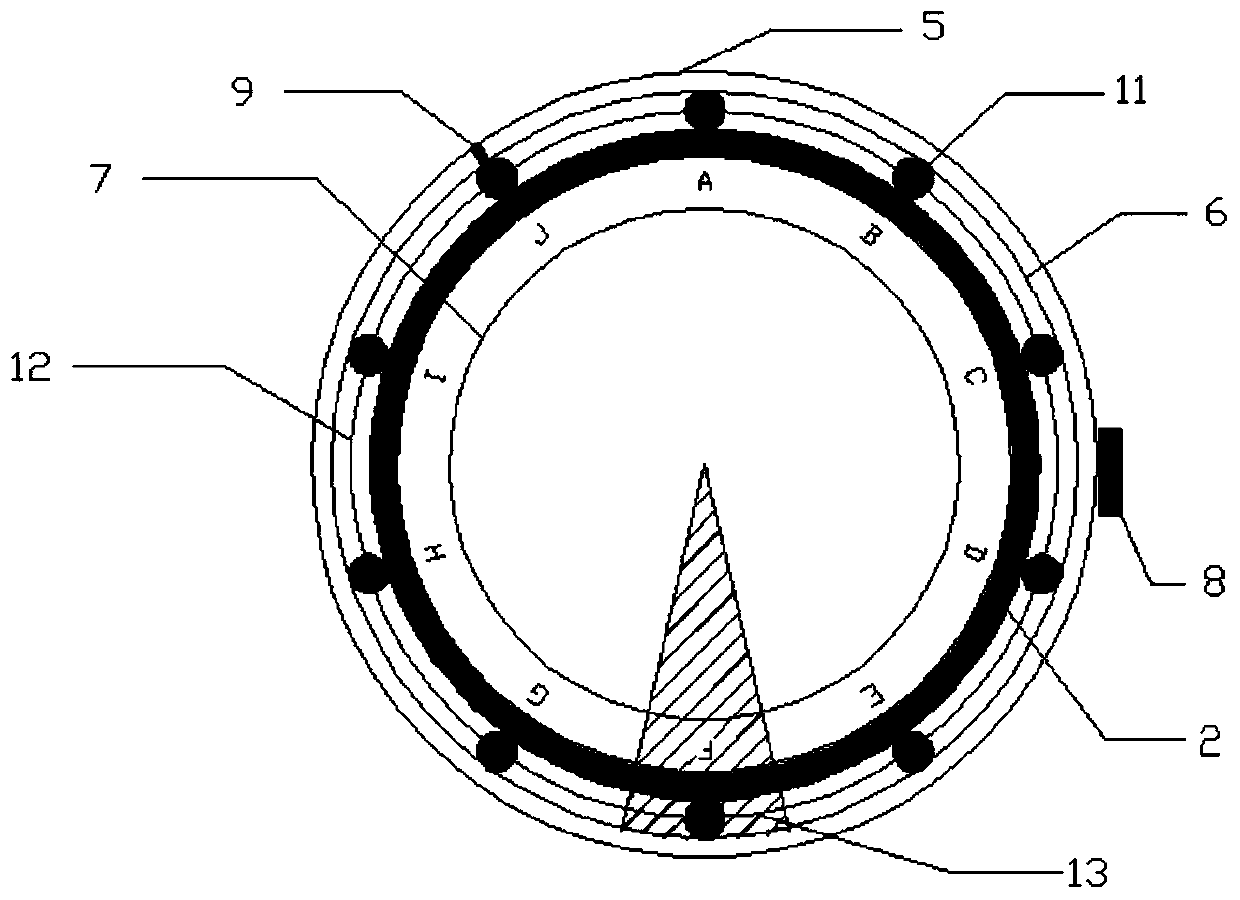

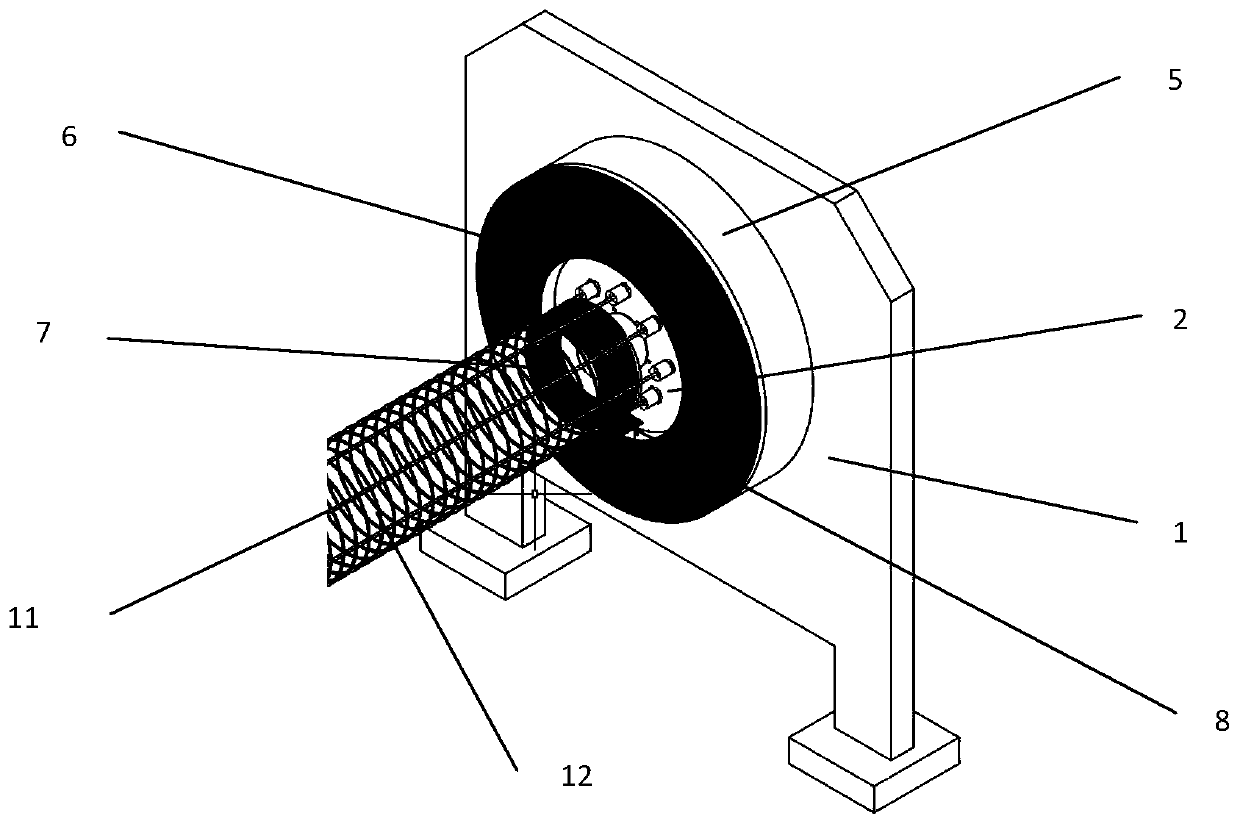

[0026] The preferred mechanism and motion realization method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] An intermediate frequency power supply energy-saving control roll welding equipment includes a calculation control system, an intermediate frequency DC power supply control system and an electromechanical system.

[0028] The operation control system of this embodiment is only described by taking the PLC control system as an example, but the operation control system may also be a single-chip microcomputer or other devices with similar functions.

[0029] The PLC control system has a high-speed data acquisition function. The interval allocation corresponding to the steel cage specification is set in the software program, and the pulse data collected by the rotary encoder 10 is collected in real time. Through calculation, the current position of the negative electrode 8 is judged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com