Multifunctional paraffin-removal, descaling and cleaning assembly

A multi-functional, wax-removing technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as the difficulty of thoroughly cleaning wax deposits on polished rods, and achieve fast and convenient installation and replacement. Improve cleaning effect and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

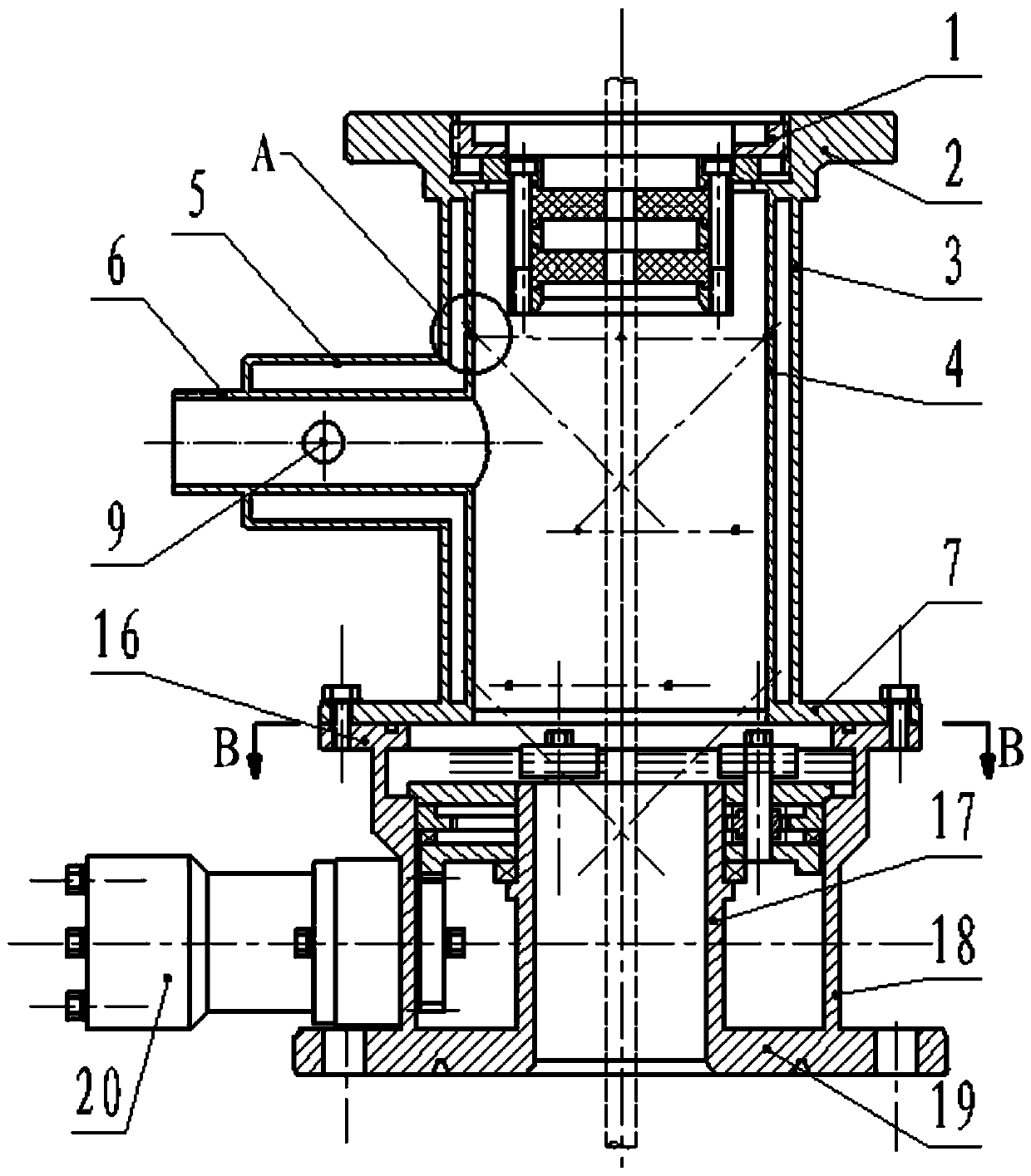

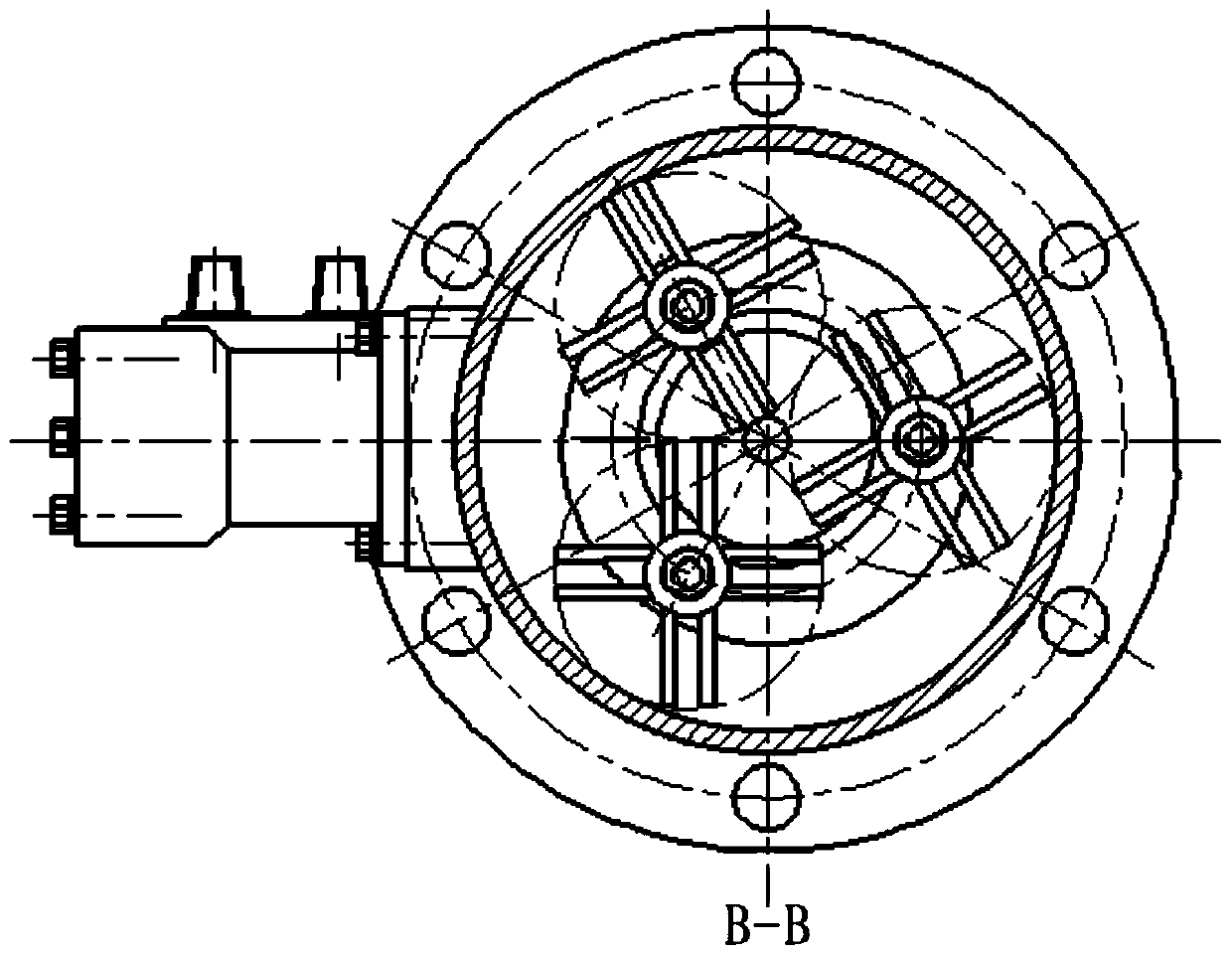

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] This embodiment includes a thermal insulation sealing steam jet cleaning device and a star compound movement wax breaking device.

[0030] The heat preservation and sealing steam jet cleaning device includes a floating self-sealing assembly, a cleaning device main body and a gland 1; the cleaning device main body includes a central cylinder 4, an outer cylinder 3, a lower connecting flange 7 and a floating self-sealing assembly carrier 2 , the outer cylinder 3 is set on the outside of the central cylinder 4 and is coaxial with the central cylinder 4, and there is an annular cavity for passing steam between the outer cylinder 3 and the central cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com