Treatment device and treatment method of aviation kerosene VOCs (volatile organic compounds)

A technology for aviation kerosene and treatment device, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of secondary pollution, frequent replacement of absorbents and absorbents, and high operating costs, so as to ensure long-term stable operation. , to avoid the deterioration of the recycling effect, and the effect of novel and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

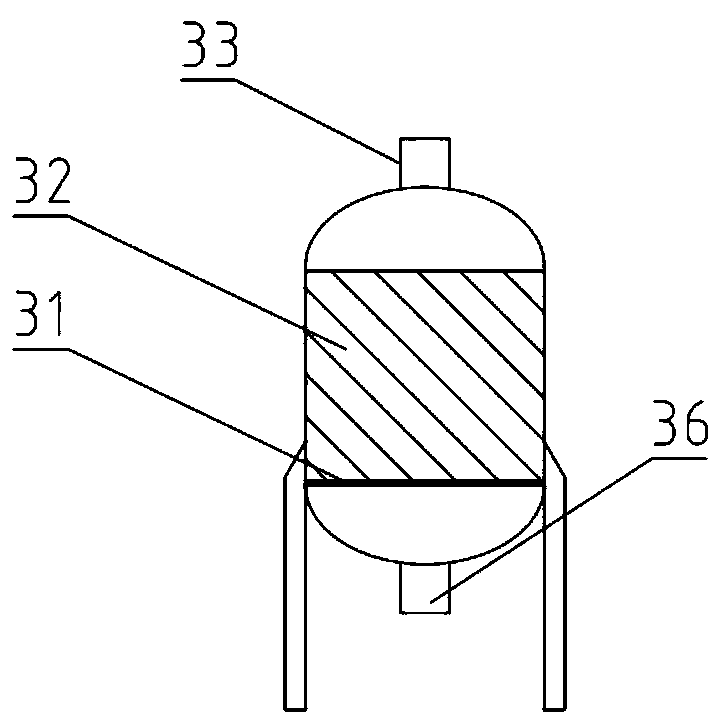

Image

Examples

Embodiment 1

[0038] In the following embodiment 1, the aviation kerosene VOCs containing non-methane total hydrocarbon concentration of 200g / m³, gas flow rate of 200Nm³ / h, and temperature of 30°C will be further described in detail as the intake example treatment source, but the present invention is also applicable It is a treatment device for aviation kerosene VOCs with different gas volumes, different concentrations, different components, and different temperatures.

[0039] Such as figure 1 As shown, the treatment device for aviation kerosene VOCs containing non-methane total hydrocarbon concentration of 200g / m³, gas flow rate of 200Nm³ / h, and temperature of 30°C includes:

[0040] Aviation kerosene VOCs collection system, the aviation kerosene VOCs collection system includes a pre-stage flame arrester 3, an induced draft fan 7, the inlet of the pre-stage flame arrester 3 is connected to the inlet of aviation kerosene VOCs 4 through a pipeline, and the inlet of the induced draft fan 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com