Hair straightener and work process thereof

A technology of hair straighteners and hair straightening parts, which is applied in the direction of curling irons, hairdressing equipment, curling or perm devices, etc., and can solve problems such as poor straightening effect, reduction of high-temperature water vapor, and insufficient market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

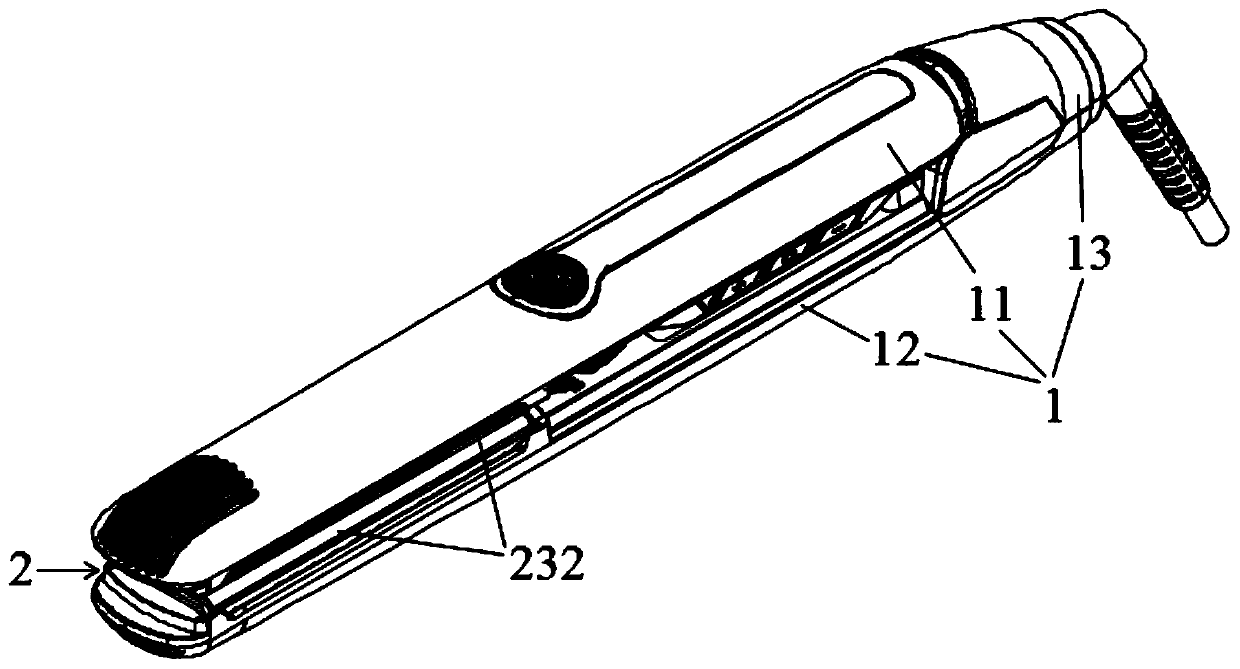

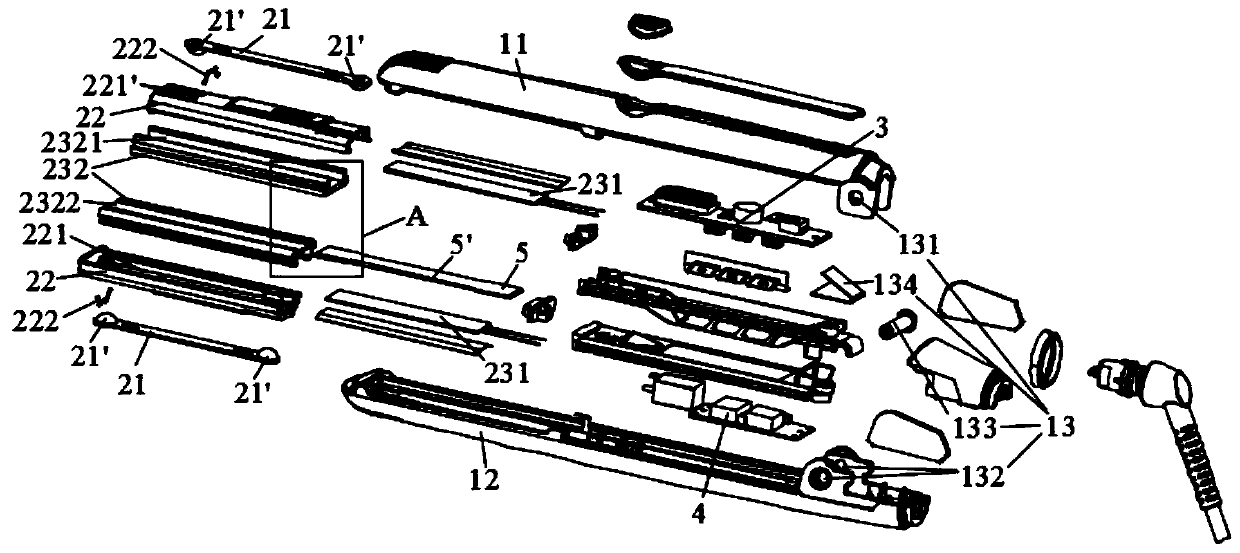

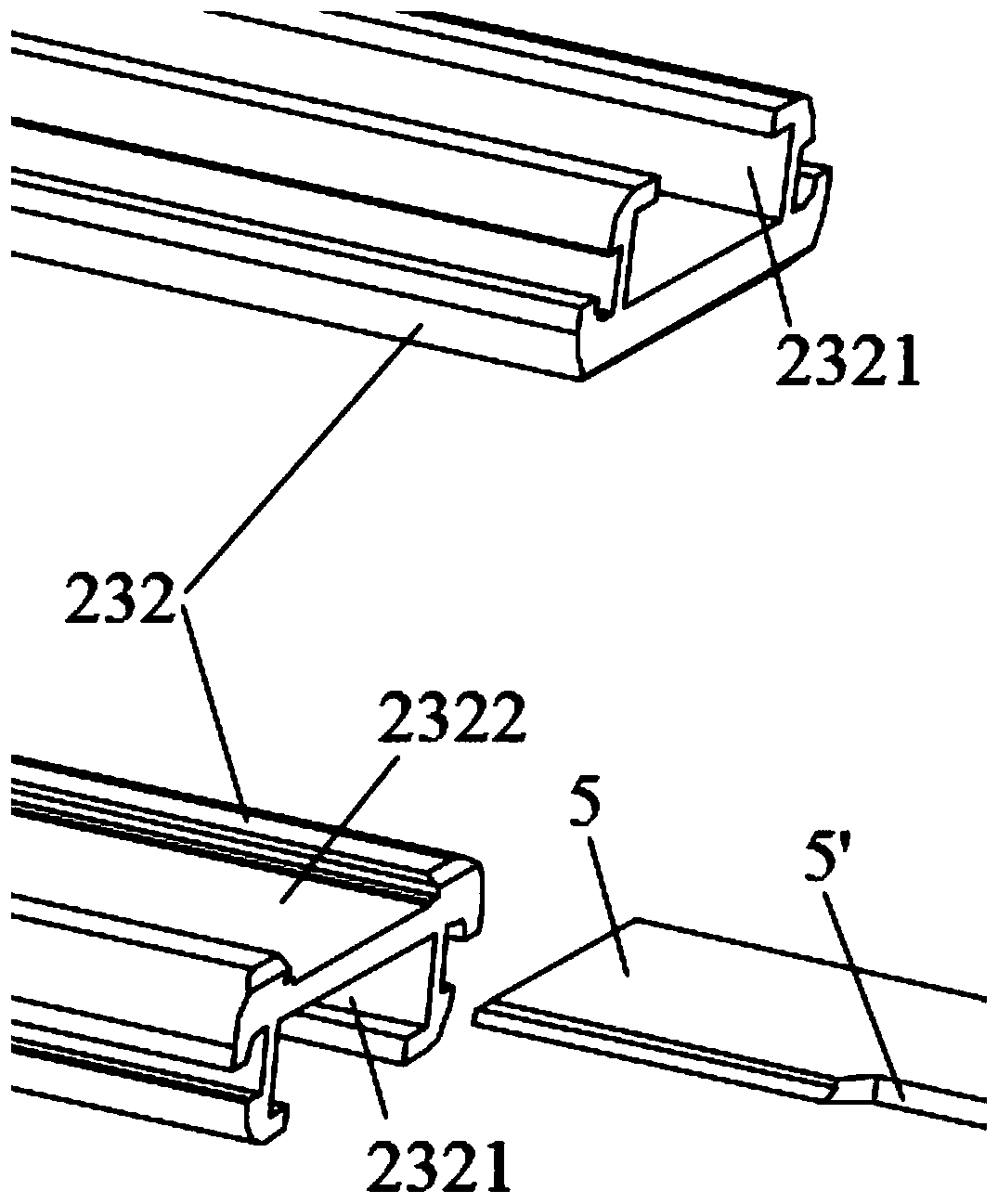

[0040] like Figure 1-5 As shown, a hair straightener includes a housing 1, two hair straightening parts 2 and a liquid storage tank 2322, the housing 1 is open, and the two hair straightening parts 2 are symmetrically accommodated in the housing 1, straight The hair part 2 includes a first elastic structure 21, a clamping structure 22, and a heating structure 23. The clamping structure 22 is connected to the housing 1 through the first elastic structure 21. The clamping structure 22 includes a receiving groove 221 and a clamp 222 for accommodating The bottom of the slot 221 is correspondingly provided with two through holes 221', and the two ends of the clamp 222 respectively pass through the two through holes 221'. The heating structure 23 includes a heating element 231 and a heat conducting sheet 232. The heat conducting sheet 232 and the heating element 231 corresponds to the contact setting, the heating element 231 is accommodated in the accommodating groove 221, the heat...

Embodiment 2

[0051] like Figure 6-7 As shown, the difference from Embodiment 1 is that there are two liquid storage tanks 2322 , and the liquid storage tanks 2322 on the two heat conducting sheets 232 are arranged correspondingly. This structural design is conducive to storing more water, thereby increasing the hair straightening effect; in practical applications, correspondingly, the two liquid storage tanks 2322 can be clamped with the liquid storage plate 5 to increase the liquid storage effect, according to the actual situation. Flexible settings.

[0052] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] like Figure 1-7 Shown, a kind of workflow of embodiment 1 or embodiment 2 hair straighteners, comprises the following steps:

[0055] S1, the control device 3 controls the heating element 231 and the negative ion generator 4 to start work, and preheats the heat conducting sheet 232;

[0056] S2. Place the wet hair between the two heat conducting sheets 232;

[0057] S3. Simultaneously press the first shell body 11 and the second shell body 12, so that the two heat conducting sheets 232 clamp the hair;

[0058] S4. Slowly push the first shell body 11 and the second shell body 12 to move toward the end of the hair;

[0059] S5. Part of the moisture on the hair flows into the liquid storage tank 2322 and is stored;

[0060] S6. Steps S3 and S4 are repeated in sequence. In step S5, the water in the liquid storage tank 2322 is heated and evaporated again, and the hair is heated with high-temperature water vapor;

[0061] Wherein, steps S3, S4, S5, S6 are executed repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com