Heat conduction comb tooth device of electric heating hair straightening comb

A comb tooth and hair straightening technology, applied in the field of hair care equipment, can solve the problems of small contact area between comb teeth and a heating plate, small contact area between comb teeth and hair, simple installation structure of comb teeth, etc. The effect of improving the efficiency of straight hair and improving the efficiency of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

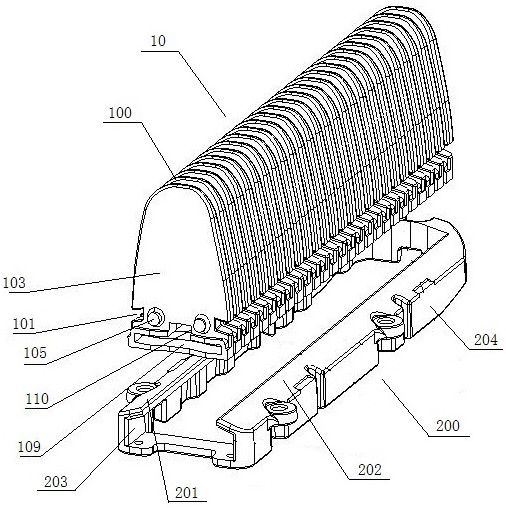

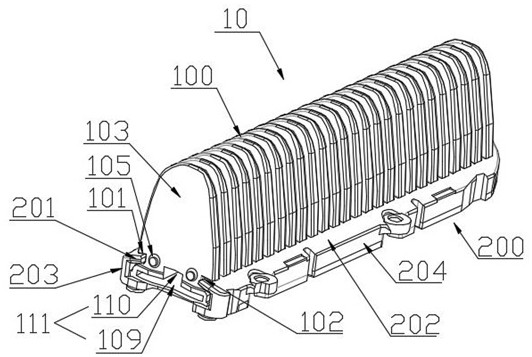

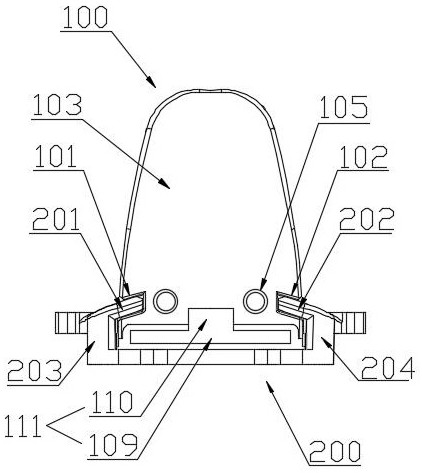

[0035] Please refer to Figure 1 to Figure 6 , figure 1 It is a disassembled structure diagram of a heat-conducting comb device of an electric hair straightening comb according to Embodiment 1 of the present invention; figure 2 It is a perspective view of a heat-conducting comb device of an electric heating hair straightening comb according to Embodiment 1 of the present invention; image 3 It is a front view of a heat-conducting comb device of an electric heating hair straightening comb according to Embodiment 1 of the present invention; Figure 4 It is a schematic diagram of the structure corresponding to the first side of the comb in the thermally conductive comb device of an electric hair straightening comb according to Embodiment 1 of the present invention; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com