Intelligent atomizing method and system

A spray system and intelligent technology, applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve the problems of increasing pesticide usage, single spraying method, unreasonable mixing, etc., to reduce pesticide usage, The effect of crop absorption is sufficient and the control effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

[0020] It should be noted that, unless otherwise specified, the technical or scientific terms used in this application should have the usual meanings understood by those skilled in the art to which the present invention belongs.

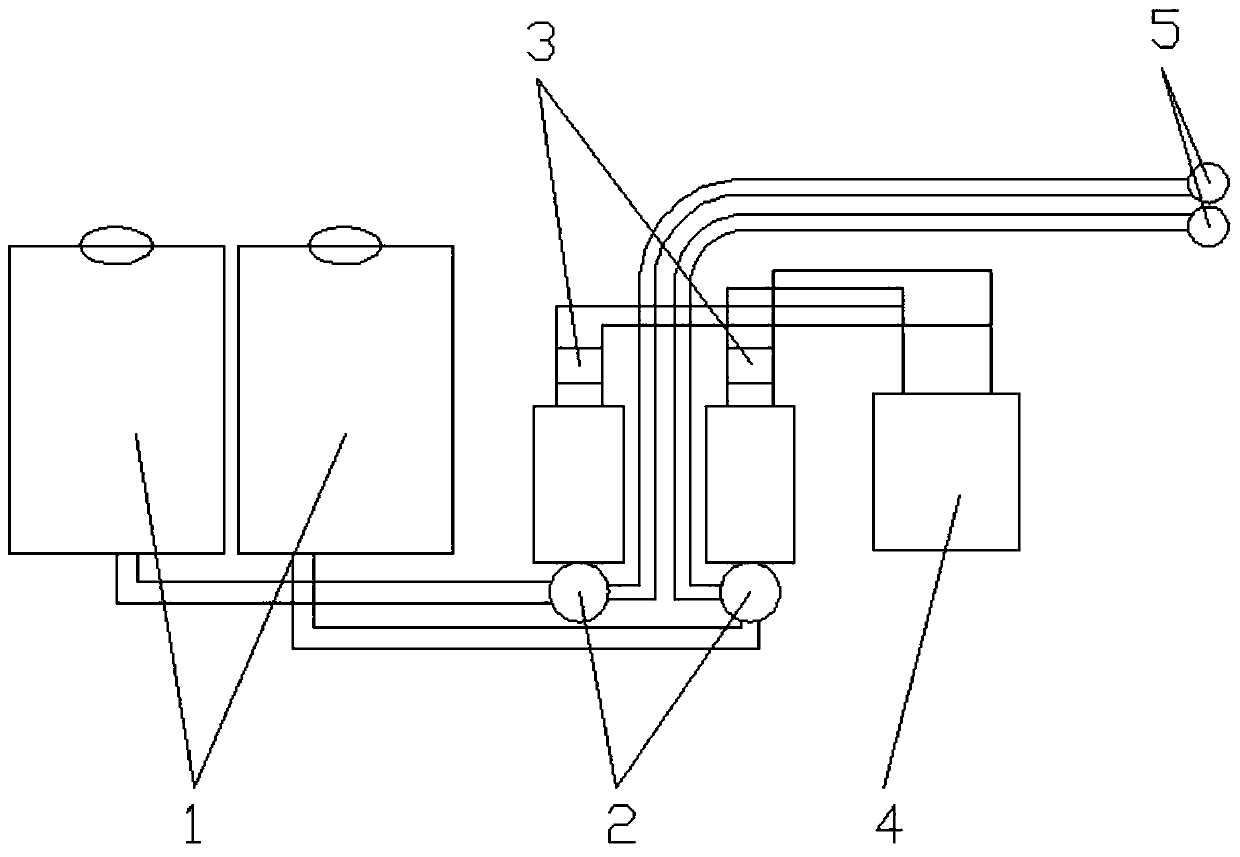

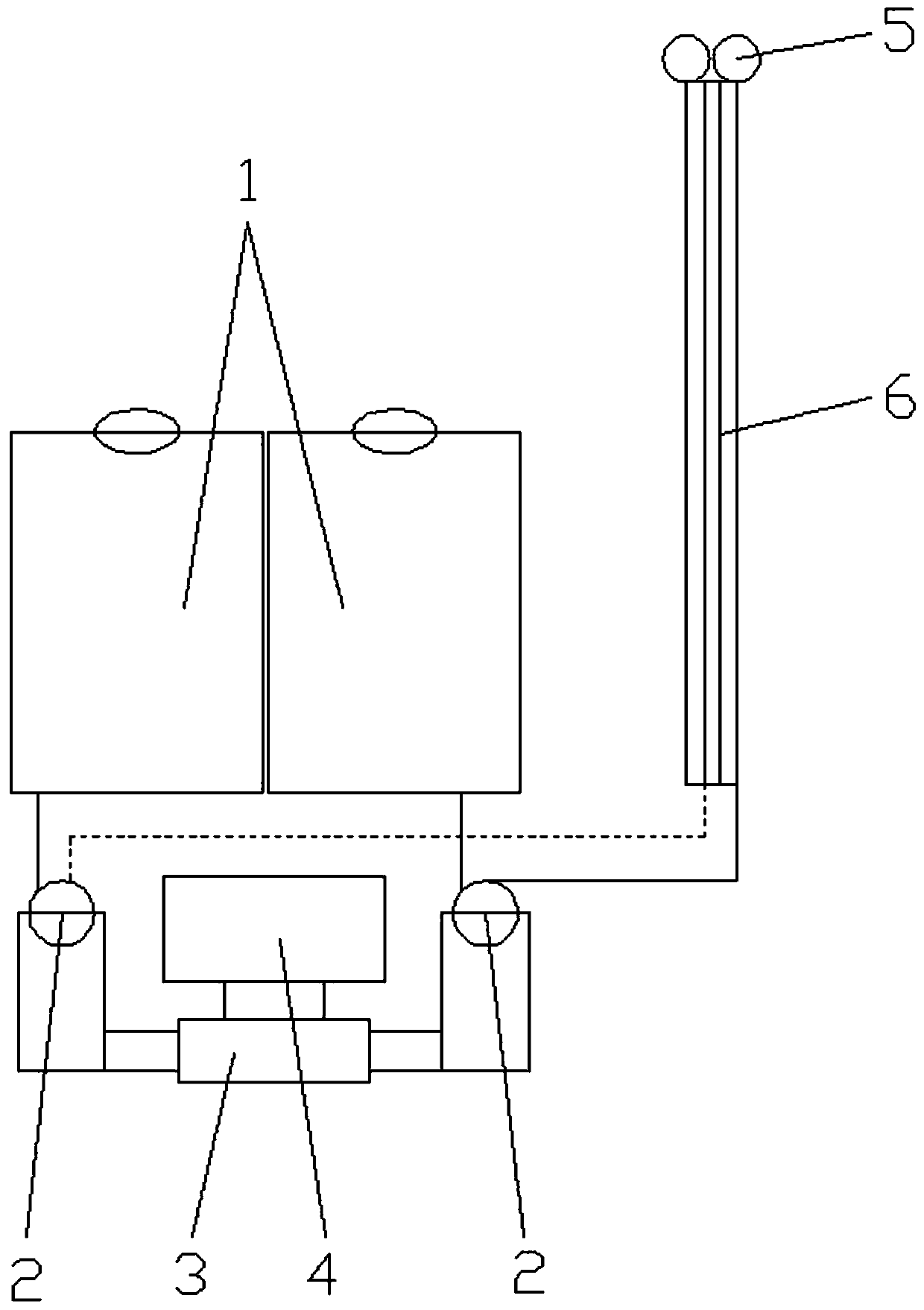

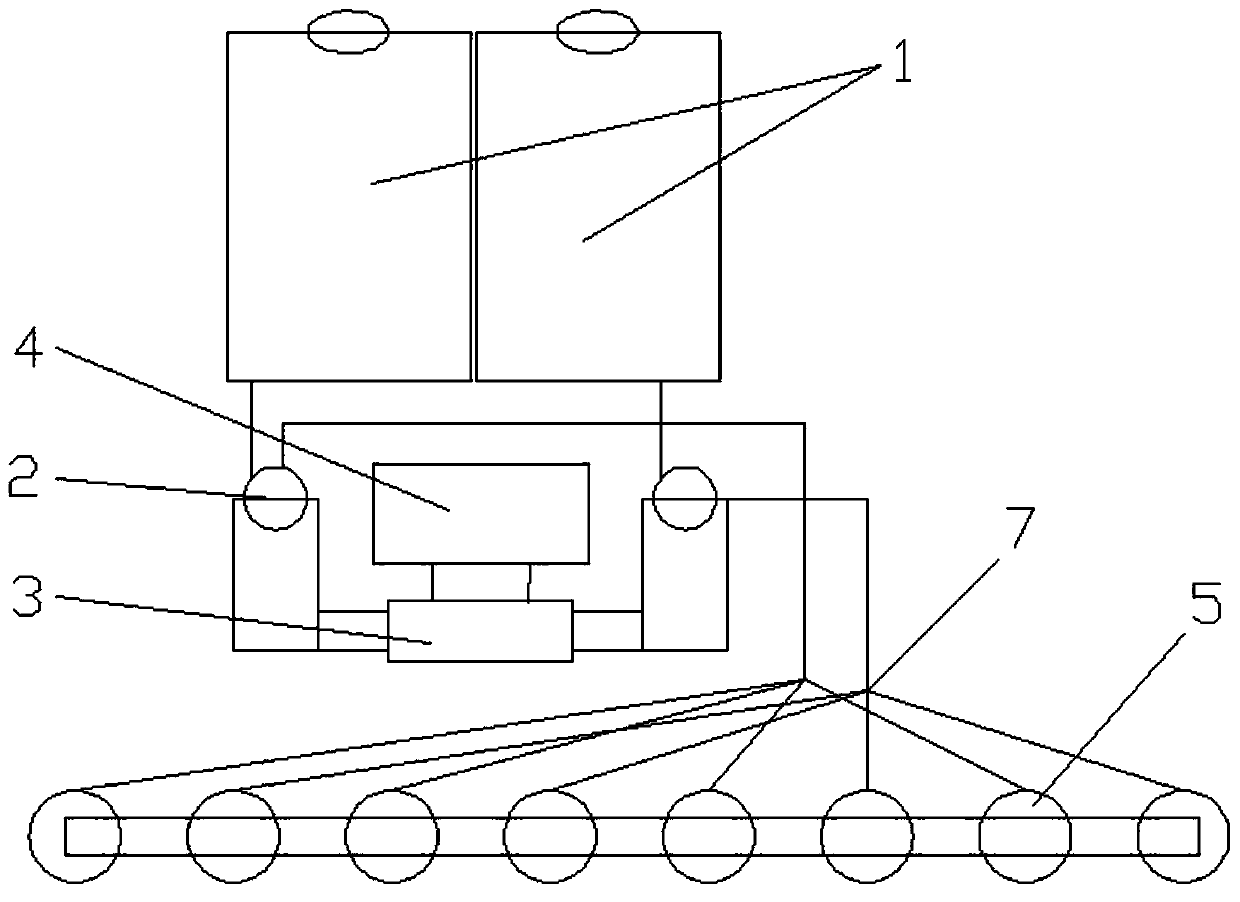

[0021] like Figure 1-5 Shown: an intelligent spraying system of this embodiment includes an energy source 4 and multiple groups of spraying components, each group of spraying components includes a medicine barrel 1, a pump group 2 and a spray head 5 connected in sequence, wherein the pump group 2 is on the An intelligent controller 3 or switch is installed and the flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com