Semiconductor device

A semiconductor and bipolar transistor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve problems such as difficulty in manufacturing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

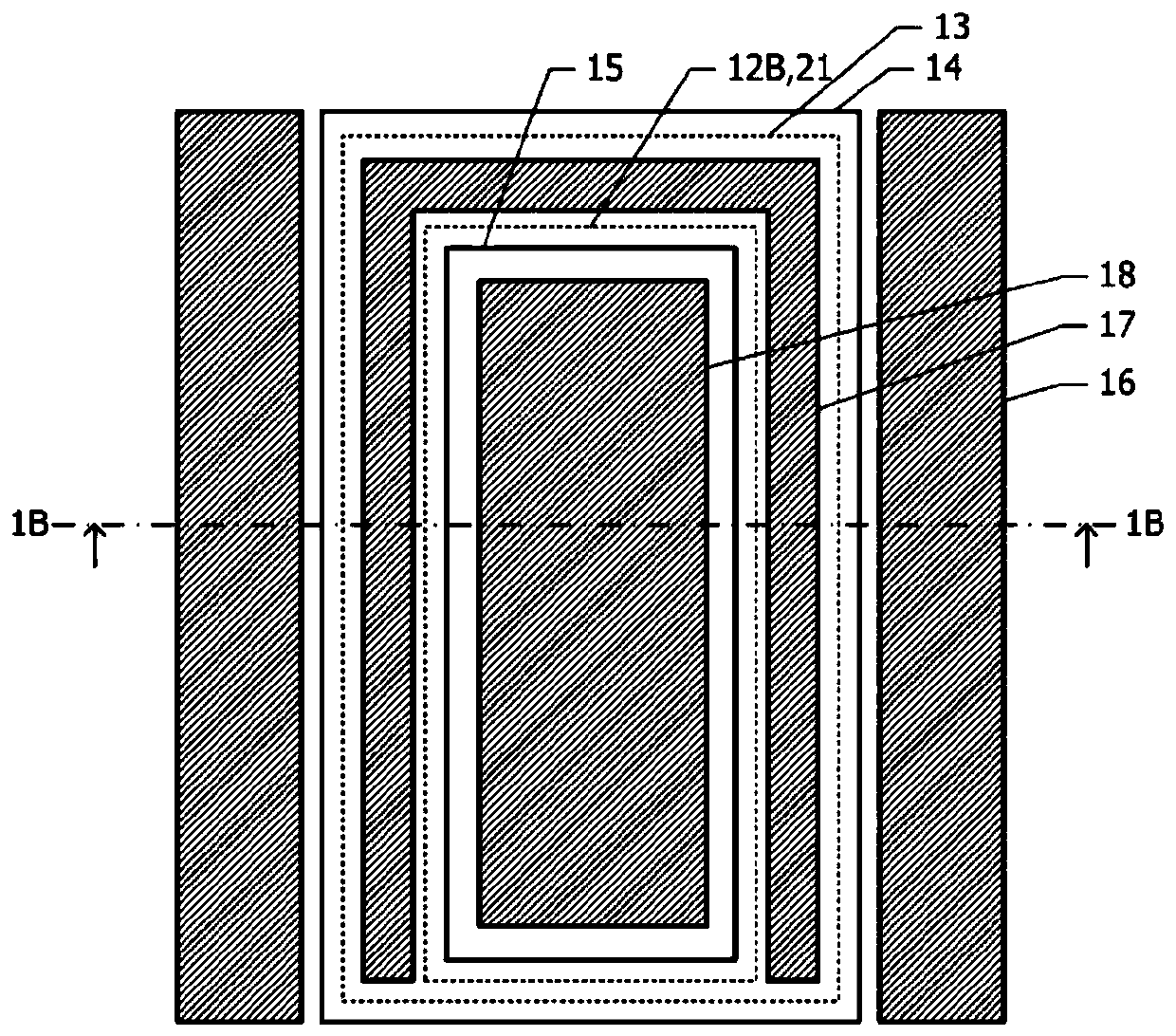

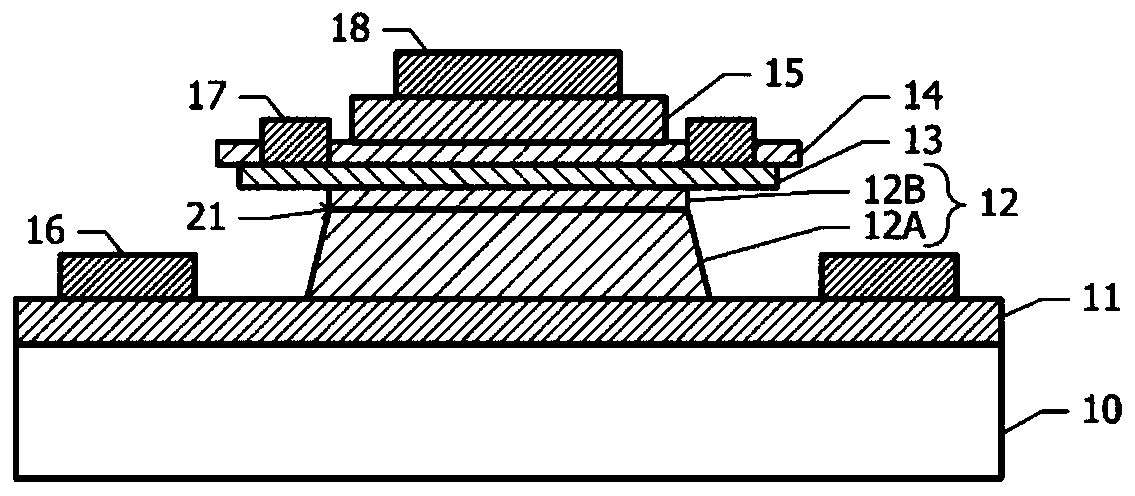

[0092] Next, refer to Figure 1A as well as Figure 1B , the semiconductor device of the first embodiment will be described.

[0093] Figure 1A is a plan view of the semiconductor device of the first embodiment, Figure 1B Yes Figure 1A The sectional view of the dotted line 1B-1B.

[0094] On a substrate 10 made of a semiconductor, a sub-collector layer 11 made of an n-type semiconductor is epitaxially grown. On the sub-collector layer 11, the collector layer 12 made of n-type semiconductor, the base layer 13 made of p-type semiconductor, the emitter layer 14 made of n-type semiconductor, and the Emitter contact layer 15. The collector layer 12 is arranged on a part of the sub-collector layer 11 .

[0095] The collector layer 12 includes a first collector layer 12A on the substrate side and a second collector layer 12B thereon. The composition of the first collector layer 12A is different from that of the second collector layer 12B, and the etching characteristics of th...

no. 2 example

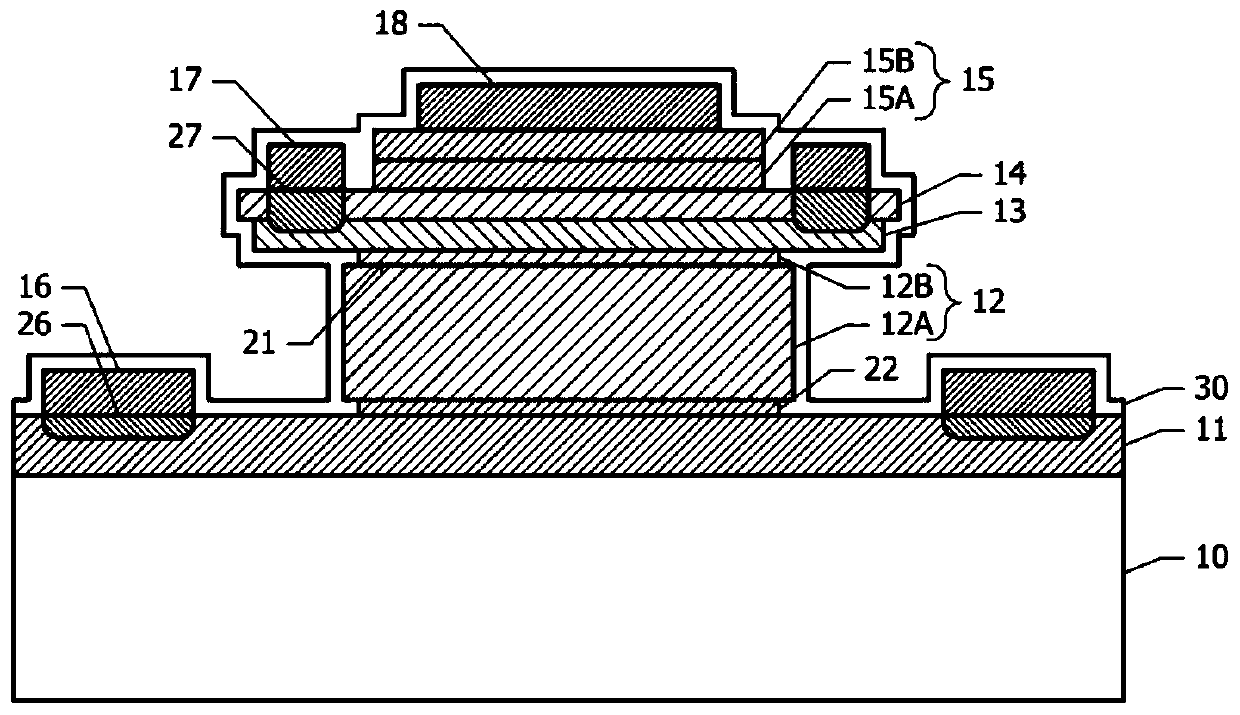

[0110] Next, refer to Figure 2 ~ Figure 3J The accompanying drawings describe the semiconductor device of the second embodiment. Below, for the first embodiment ( Figure 1A , Figure 1B ) The description of the same configuration as the semiconductor device is omitted.

[0111] figure 2 is a cross-sectional view of the semiconductor device of the second embodiment. In the second embodiment, an etching stopper layer 22 is disposed between the sub-collector layer 11 and the first collector layer 12A. Etching stopper layer 22 has an etching characteristic different from those of first collector layer 12A and sub-collector layer 11 . In a plan view, the edge of the upper surface of the etching stopper layer 22 is arranged on the inner side than the edge of the lower surface of the first collector layer 12A.

[0112] The conductivity type of the etching stopper layer 22 is the same as that of the sub-collector layer 11 , and the doping concentration of the etching stopper l...

no. 3 example

[0148] Next, refer to Figure 4A as well as Figure 4B , the semiconductor device of the third embodiment will be described. Hereinafter, for the semiconductor device of the second embodiment ( figure 2 ) with the same configuration is omitted.

[0149] In the second embodiment, the second collector layer 12B ( figure 2 ) uses InGaP, but in the third embodiment, InGaPN is used. The molar ratio of In to Ga is 0.528:0.472, and the molar ratio of P to N is 0.995:0.005. At this time, the electron affinity of the second collector layer 12B is almost equal to the electron affinity of the base layer 13 made of GaAs. In the third embodiment, the doping concentration of the second collector layer 12B is also the same as that of the second collector layer 12B of the semiconductor device of the second embodiment.

[0150] Figure 4A as well as Figure 4B are the semiconductor devices of the third embodiment and the second embodiment ( figure 2 ) energy band diagrams of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com