Light source device for SMD wafer ultra-micro masked crack detection

A technology for crack detection and light source device, which is used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. Detection efficiency and detection accuracy, the effect of efficient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

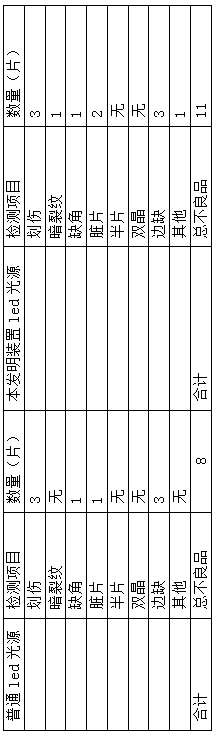

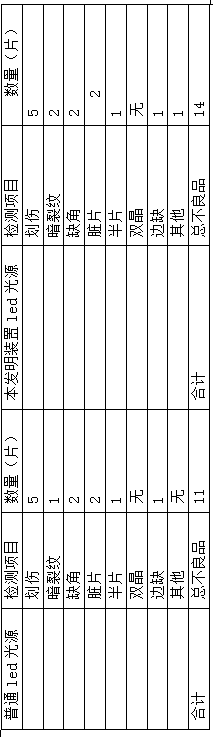

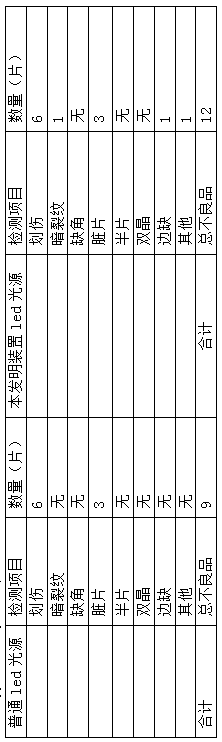

[0019] Combine below figure 1 , to further illustrate the present invention.

[0020] Such as figure 1 As shown, a light source device for detecting ultra-dark cracks in SMD wafers, including a light-condensing tube 1, the upper side of the light-condensing tube 1 is connected to the upper light source 4 through the light-condensing tube gland 2, and the light-condensing tube 1. The lower side is connected to the lower light source 5 through the lower rotating plate 3; the upper light source 4 is a vertical light source, and the lower light source 5 is an oblique light source with an inclination angle of 61-64°; the upper light source 4 is composed of 96 LEDs The electric beads are evenly distributed in two rows, and the inner diameter of the light source is 60-62 mm. The lower light source 5 is divided into three rows of 145 LED resistors, and the inner diameter of the light source is 64-65 mm.

[0021] Since SMD wafers not only have dark cracks below 0.009mm, but also have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com