A lining structure suitable for tunnels crossing active faults and its construction method

A technology for active faults and tunnels, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of affecting the self-weight of lining structures, increasing rigidity, and small applicability, so as to facilitate rapid clearance, strengthen integrity and stability, The effect of shifting energy is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a lining structure suitable for tunnels crossing active faults, and optimizes the tunnel lining structure during tunnel construction to reduce earthquake damage to the tunnel.

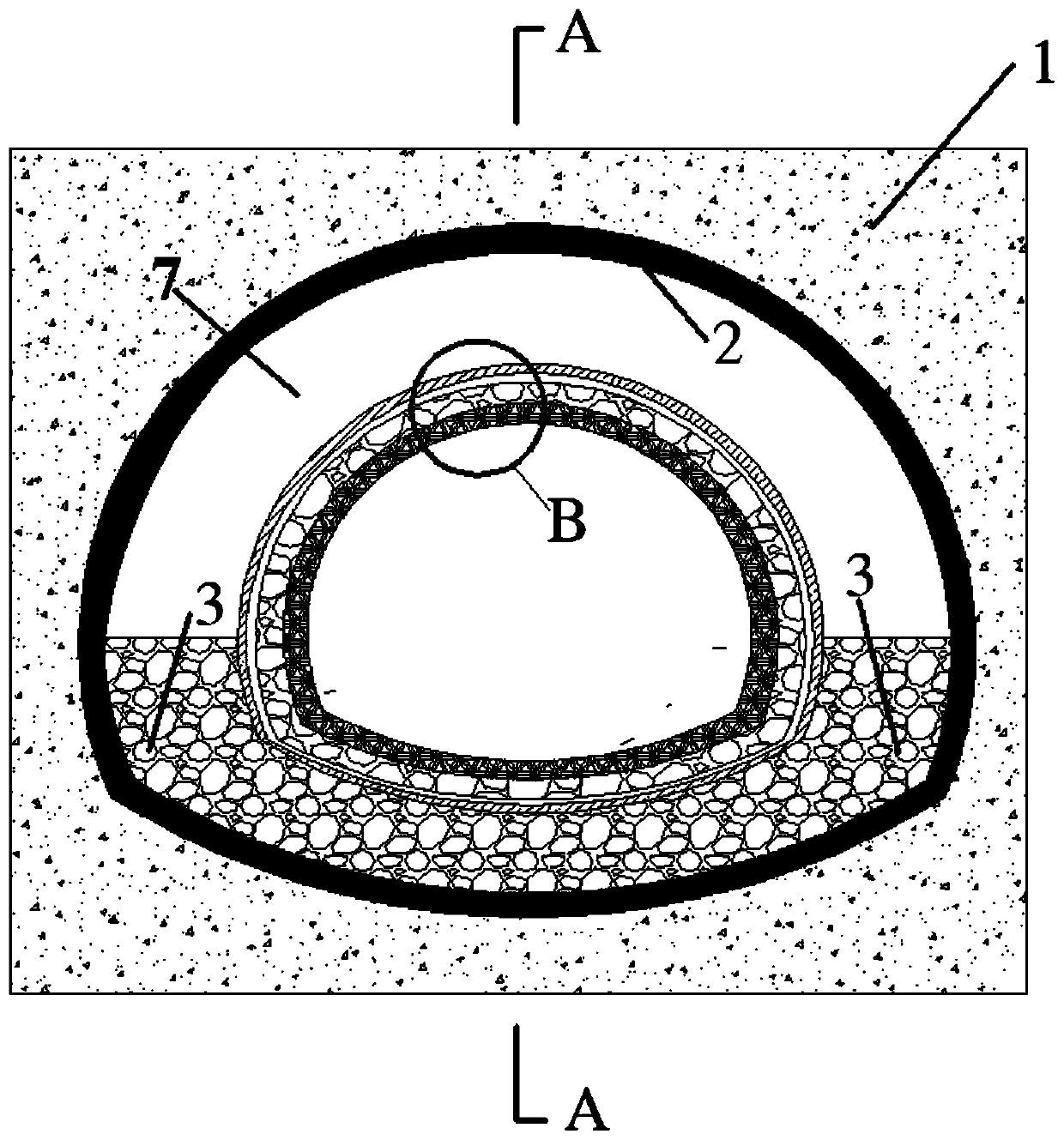

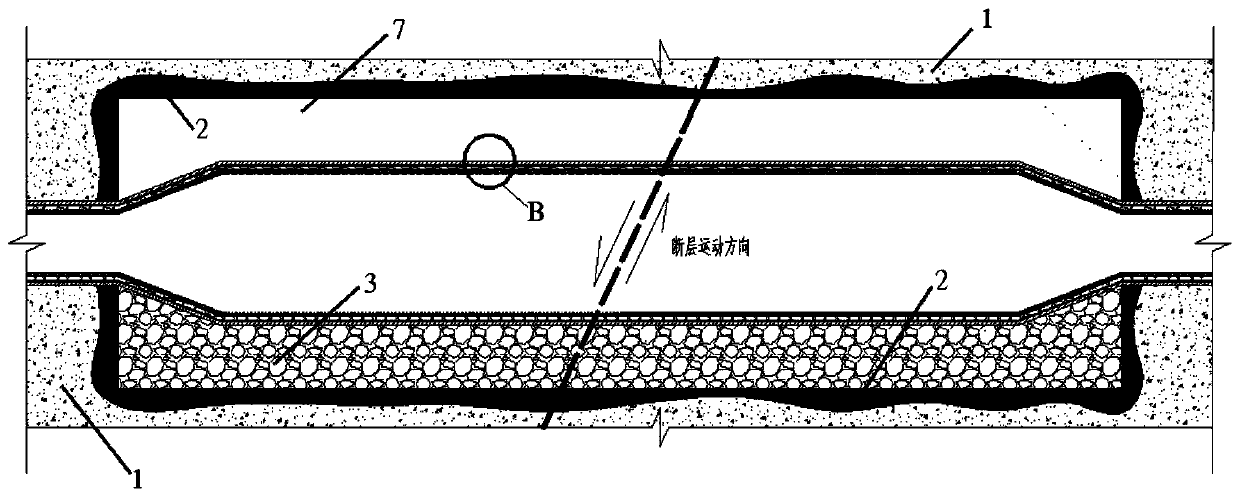

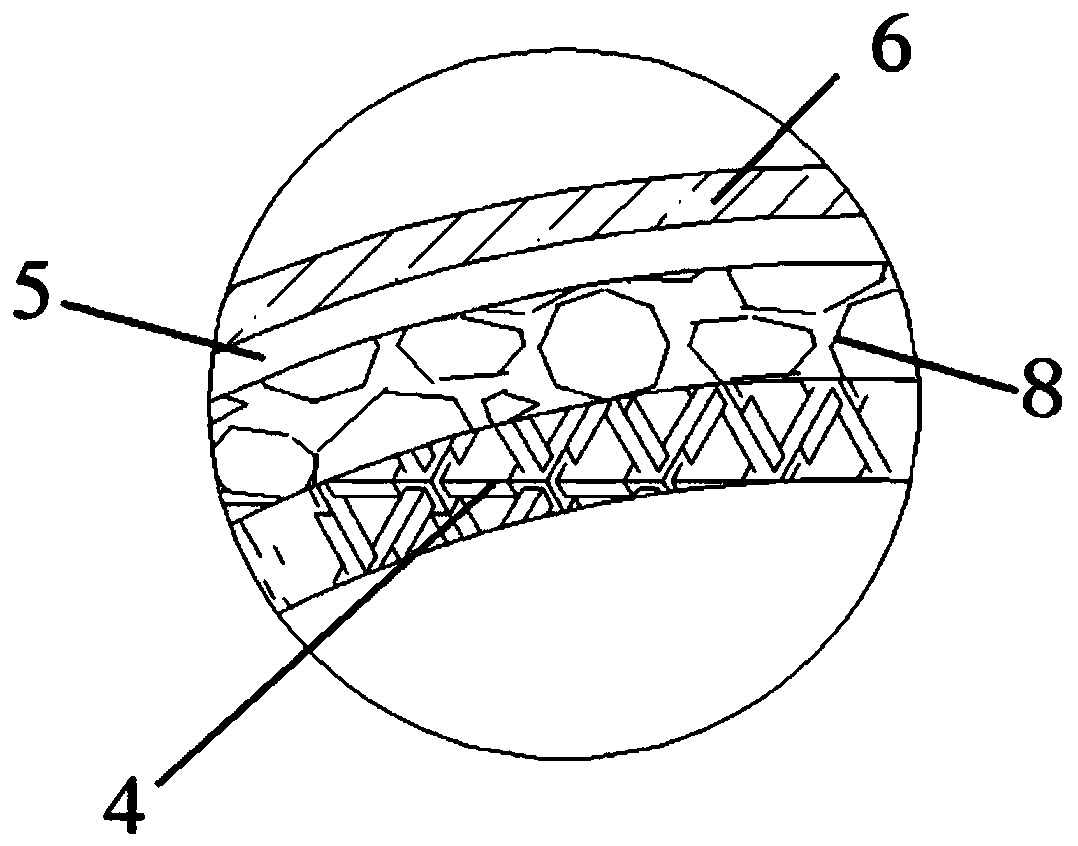

[0034] Please refer to the attached figure 1 with 2 , the lining structure suitable for tunnels crossing active faults proposed in this implementation includes a grouting reinforcement layer 2 and a tunnel support structure, the grouting reinforcement layer 2 is arranged on the excavation surface of the tunnel surrounding rock 1, and the tunnel support structure Set on the inner side of the grouting reinforcement layer 2, a clearance deformation layer 7 is reserved between the grouting reinforcement layer 2 at the upper part of the tunnel and the tunnel support structure, and a second An energy-dissipating and shock-absorbing layer 3 .

[0035] In this embodiment, the thickness of the clearance deformation layer 7 is 30-50 cm, and its function is: when the active fault...

Embodiment 2

[0046] This embodiment provides a construction method suitable for a lining structure of a tunnel crossing an active fault, and optimizes the tunnel lining structure during tunnel construction to reduce earthquake damage to the tunnel.

[0047] Please refer to the attached figure 1 , the construction method suitable for the lining structure of the tunnel crossing the active fault comprises the following steps:

[0048] S101, within the range of 50-100m near the active fault fracture zone, gradually increase the excavation surface area, reserve a clearance deformation layer between the excavation surface of the tunnel surrounding rock and the upper part of the tunnel, and reserve a clearance deformation layer between the excavation surface and the bottom of the tunnel Apply the first energy-dissipating shock-absorbing layer.

[0049] S102, the cross-sectional area of the tunnel at the fault fracture zone is greater than that at the stable section.

[0050] S103, when passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com