Vehicle bumper device

A technology for bumpers and vehicles, applied in the directions of bumpers, vehicle parts, vehicle safety arrangements, etc., can solve the problems of easy reduction, easy deformation and load resistance, and achieve the effect of suppressing the reduction of load resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

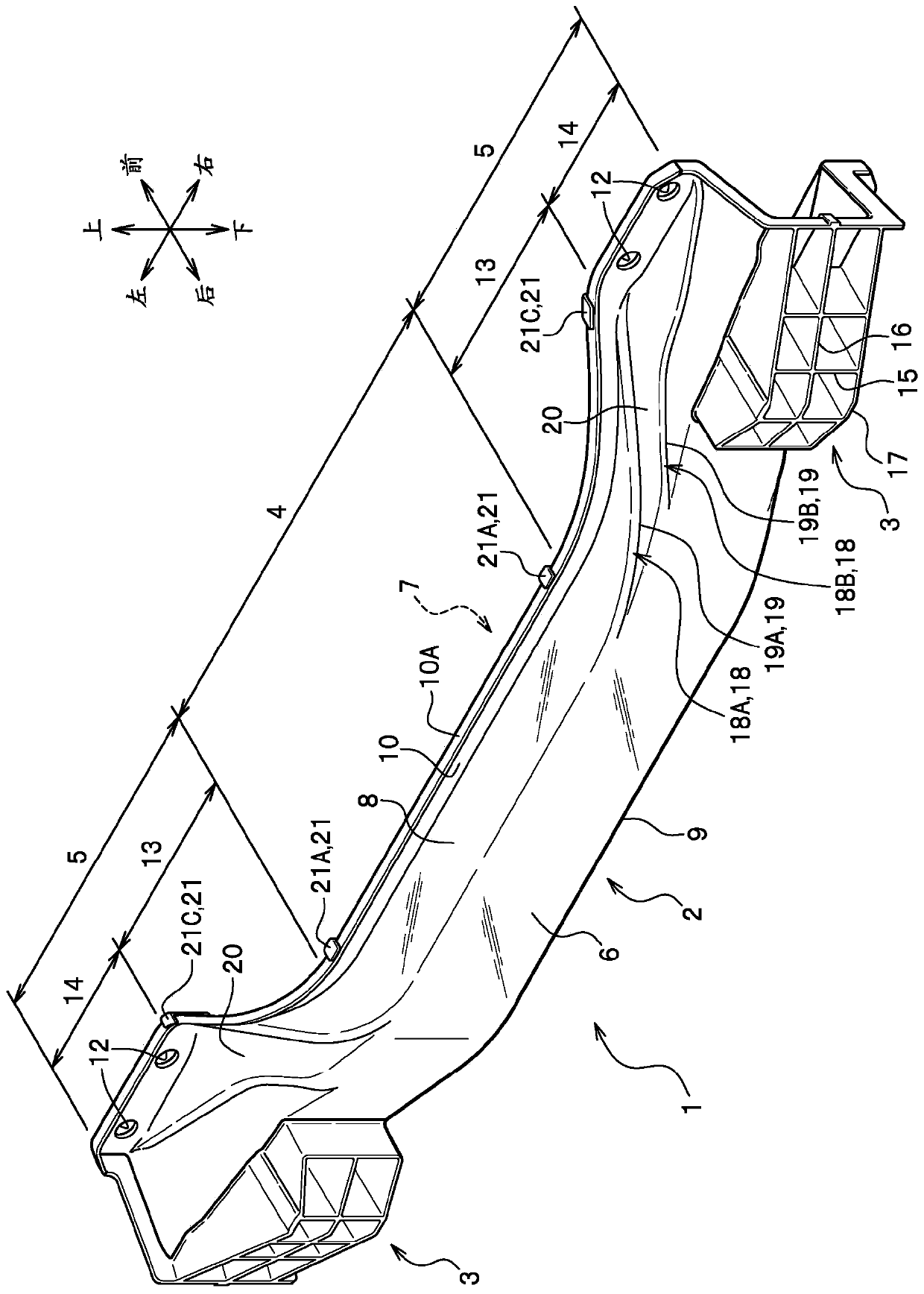

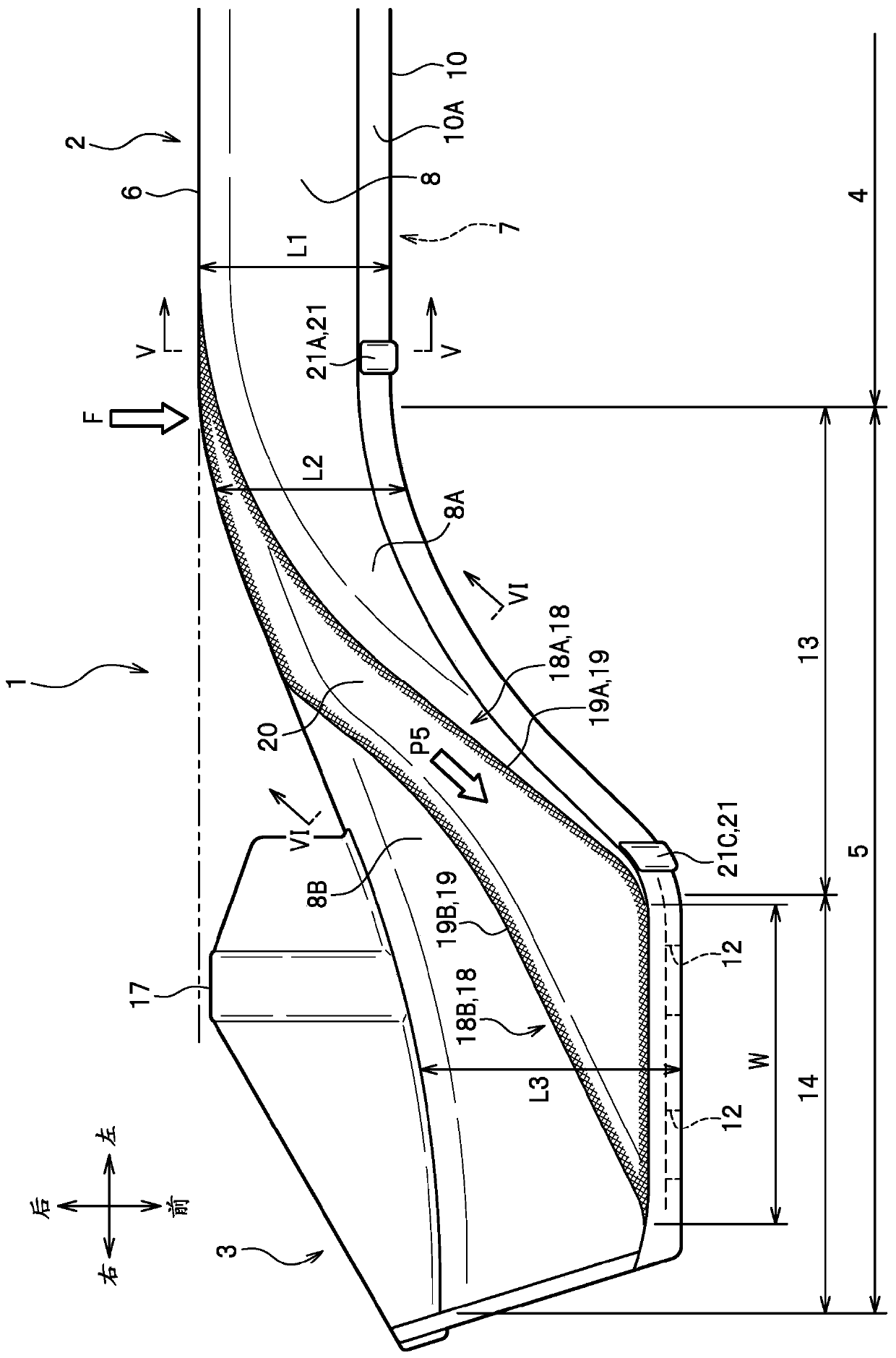

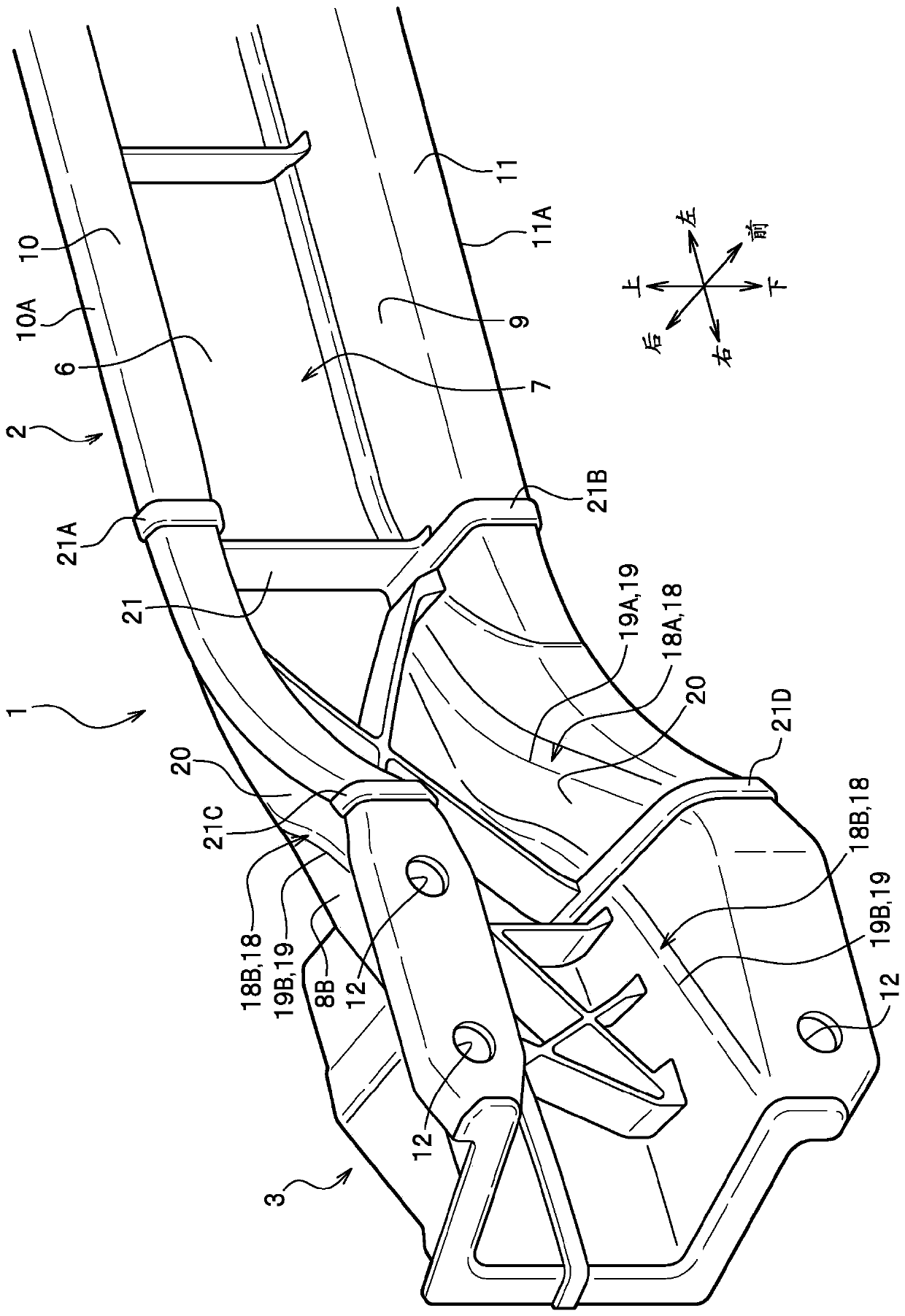

[0035] Hereinafter, a case where the present invention is applied to a rear bumper device of a vehicle will be described, but the present invention can also be applied to a front bumper device of a vehicle.

[0036] refer to Figure 1 to Figure 3 , the vehicle bumper device 1 is configured to include a bumper beam 2 and a bumper auxiliary portion 3 . The bumper beam 2 is formed of continuous fiber resin. The continuous fiber resin is, for example, thermoplastic CFRP (Carbon Fiber Reinforced Plastics: carbon fiber reinforced plastics). Such as Figure 4 As shown in (a), the continuous fiber resin includes a thermoplastic resin R arranged in a matrix and carbon fibers C1 composed of long fibers. The carbon fibers C1 are regularly oriented. On the other hand, the bumper auxiliary part 3, which will be described in detail later, is formed of short-fiber resin. Such as Figure 4 As shown in (b), the short fiber resin includes the thermoplastic resin R and the carbon fiber C2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com