Distributed type hub motor electric vehicle heat management system and control method

A thermal management system and in-wheel motor technology are applied in the field of distributed in-wheel motor electric vehicle thermal management system and control, which can solve the problem that the thermal management system is complex and the vehicle thermal management system cannot well meet the thermal management requirements and efficiency of the vehicle. It can achieve the effect of realizing recycling, improving utilization rate and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

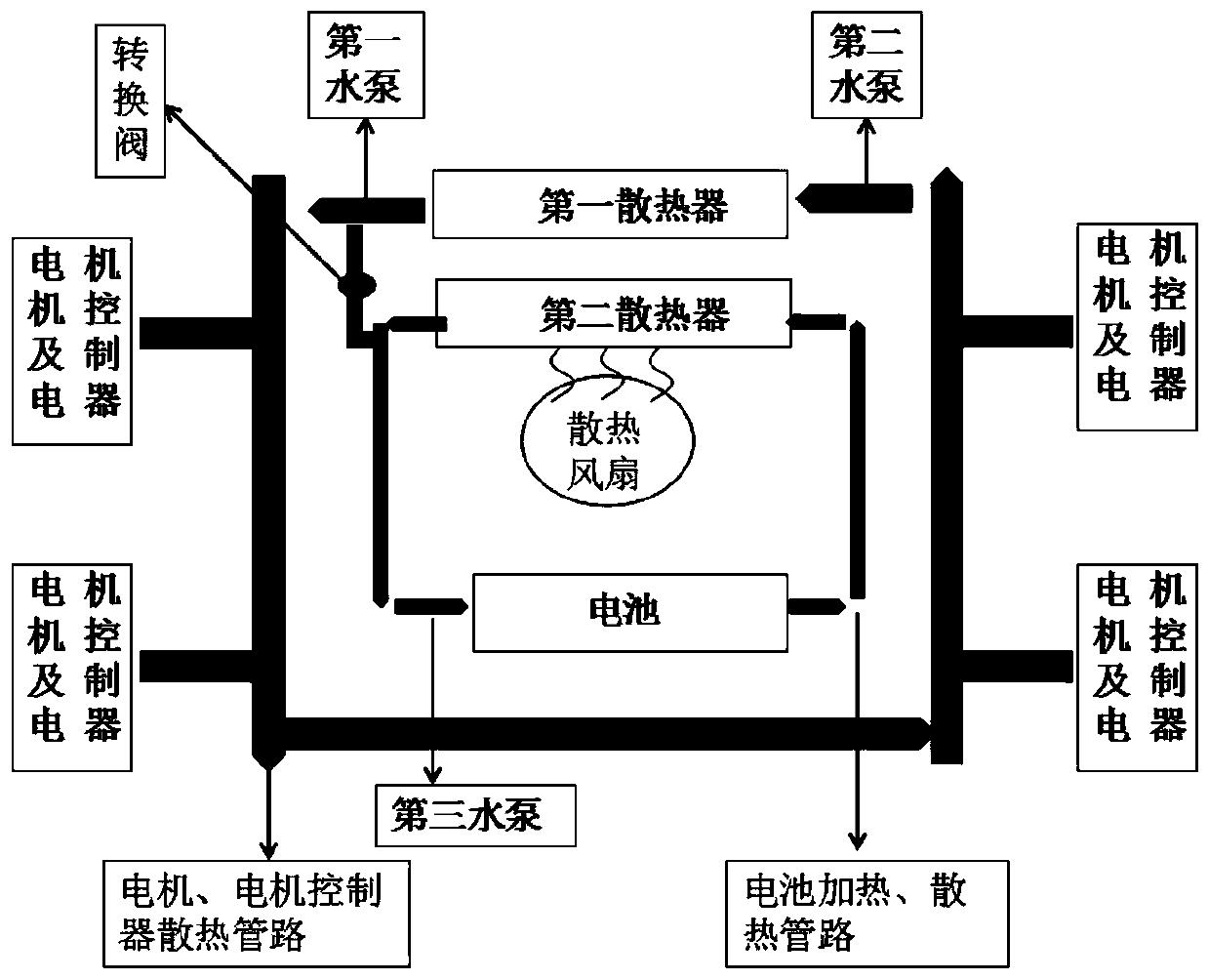

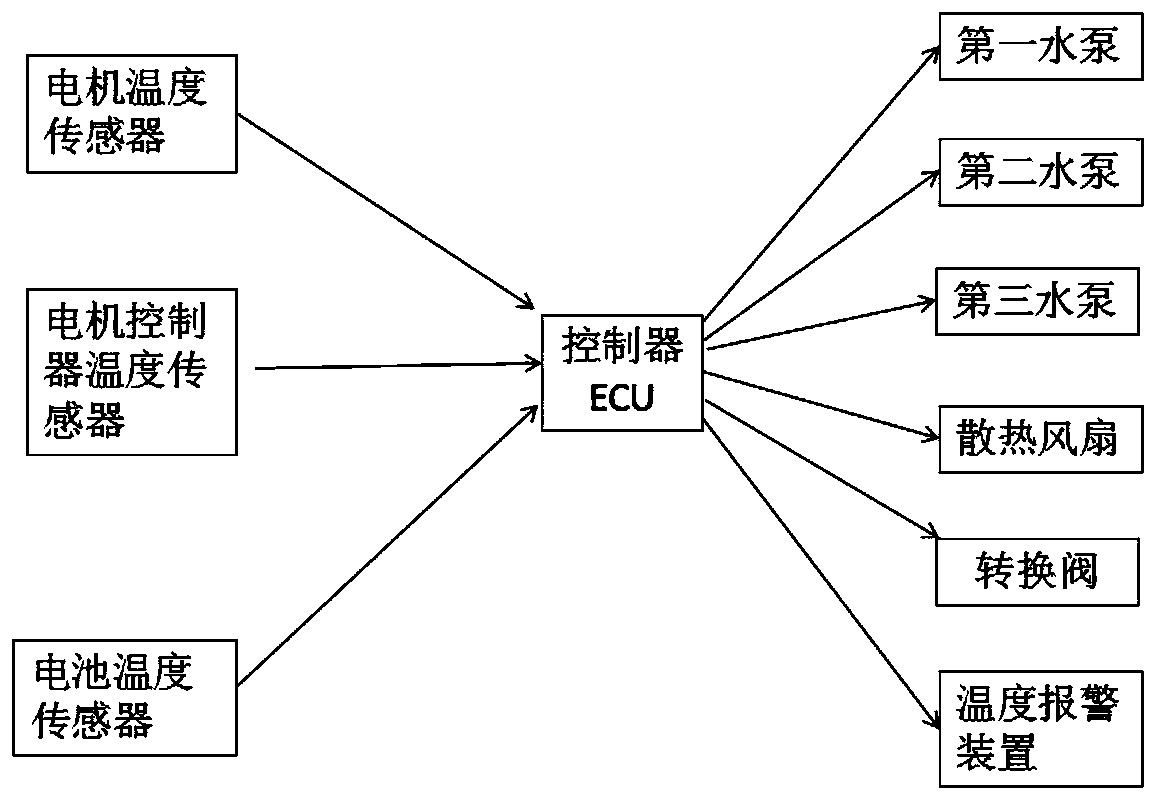

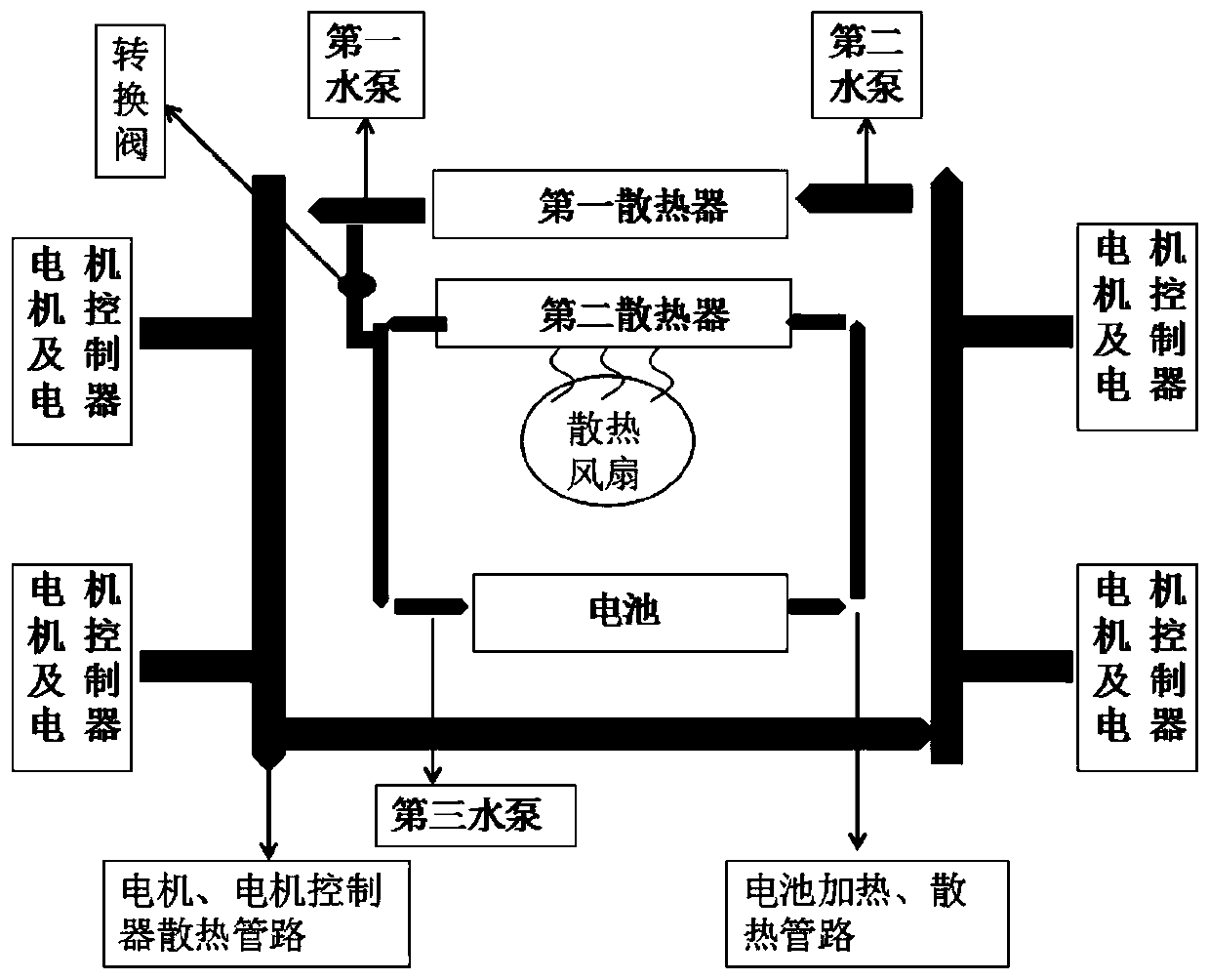

[0025] combine figure 1 , a thermal management system for a distributed in-wheel motor electric vehicle of the present invention, comprising a first radiator, a first water pump, a second water pump, a second radiator, a third water pump, a switching valve, a controller; a motor temperature sensor, a motor Controller temperature sensor, battery temperature sensor.

[0026] The water outlet end of the first radiator is connected to the water inlet end of the first water pump, and the water inlet end of the first radiator is connected to the water outlet end of the second water pump; the first water pump is used to pump the coolant of the first radiator into the motor and the motor controller In the water jacket; the second water pump is used to pump the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com