Novel large-angle rotation horizontal band sawing machine

A large-angle, band sawing machine technology, applied in the field of sawing machines, can solve the problems of reducing the sawing flexibility of the sawing frame to the workpiece, affecting the positional flexibility of the workpiece clamping device, etc., achieving flexible angles and positions, and ingenious structural design , flexible rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

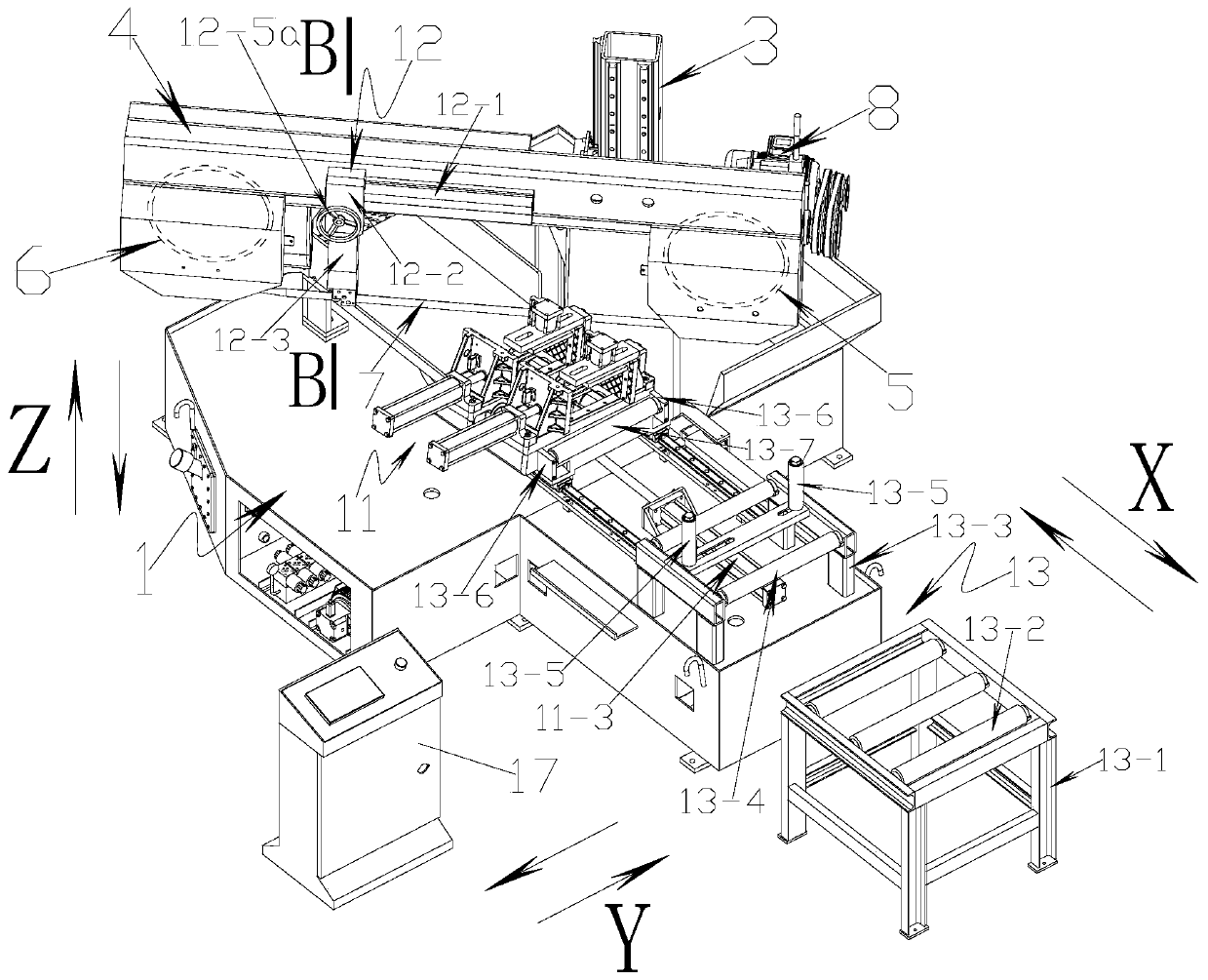

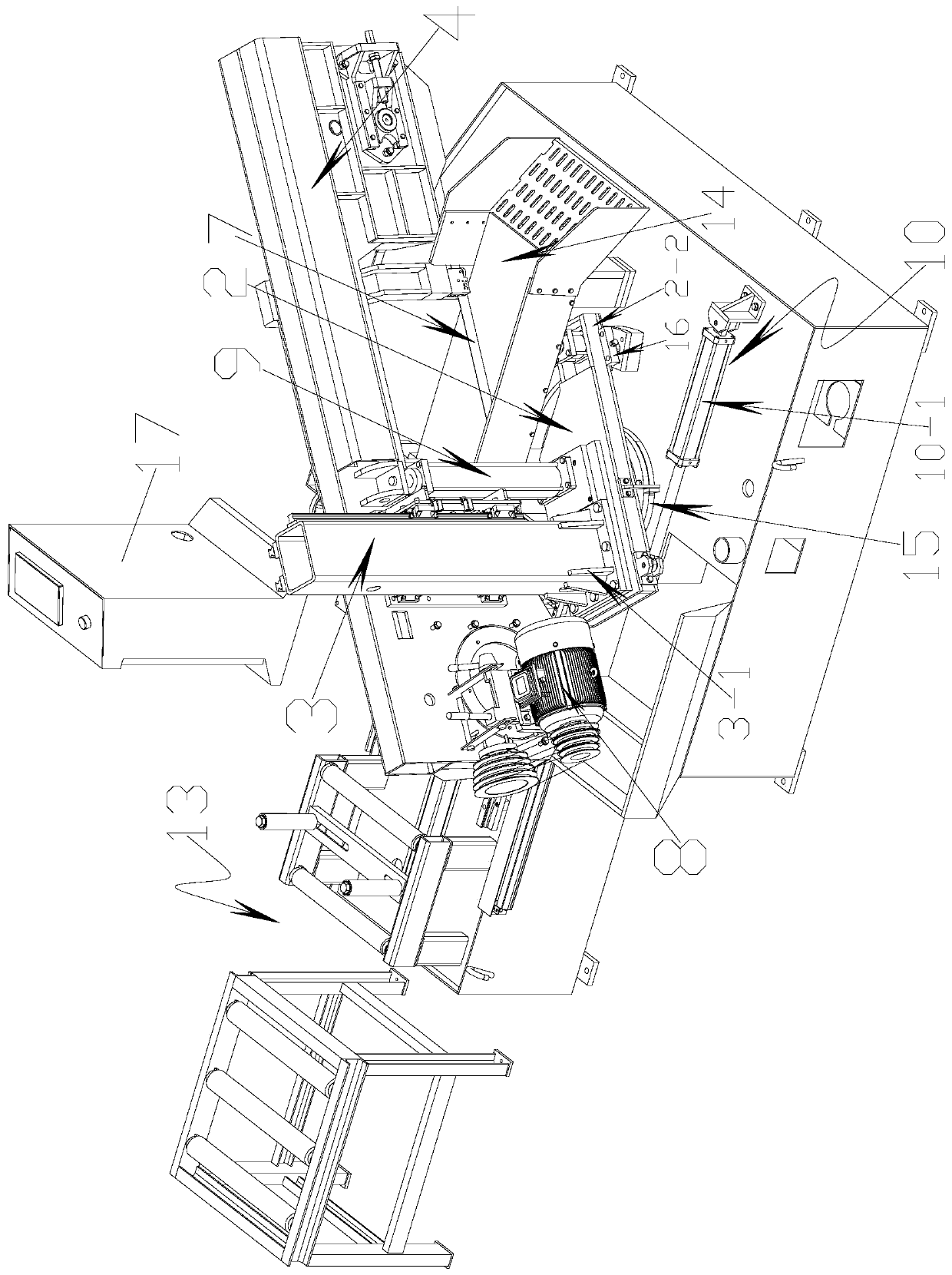

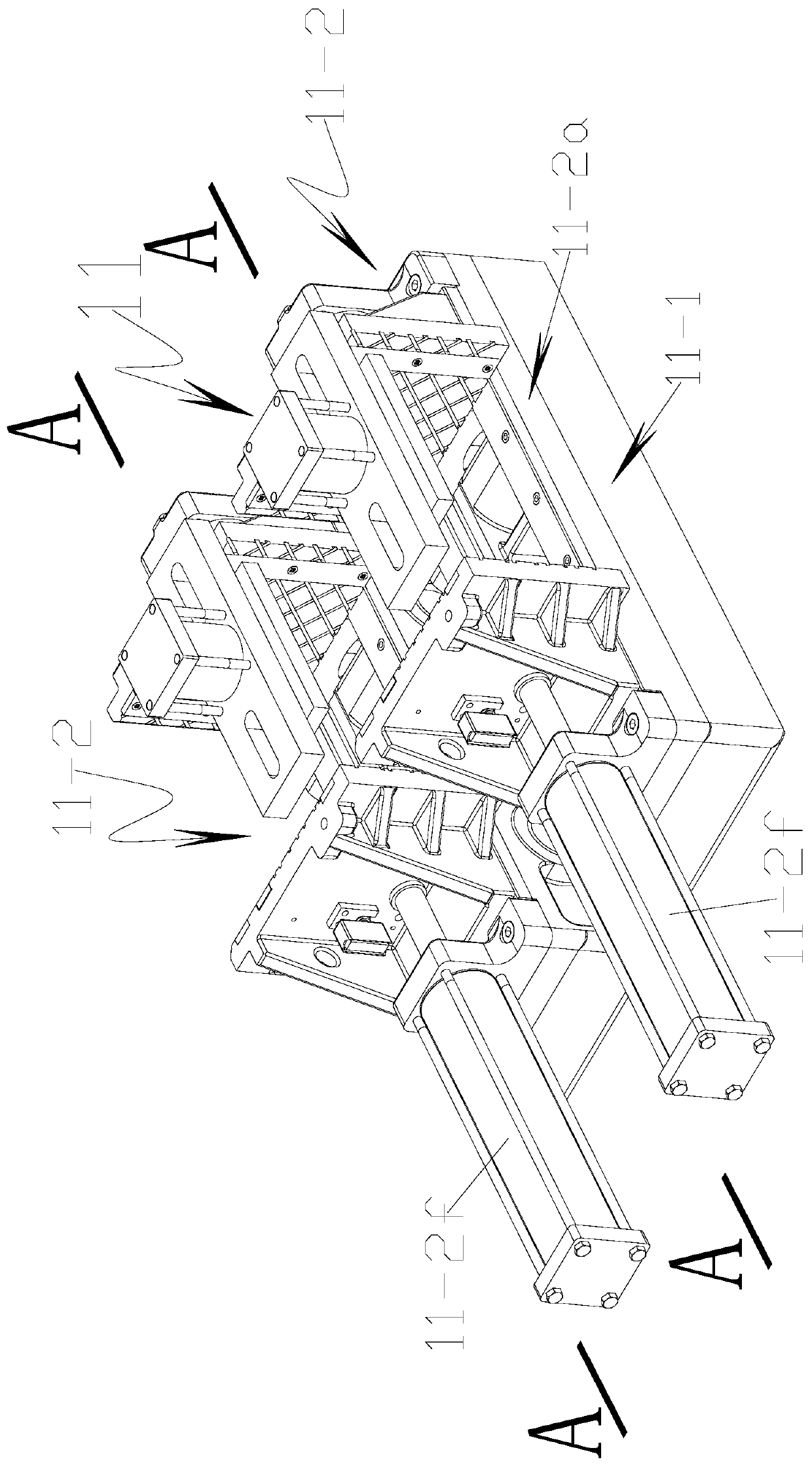

[0026] Refer to attached figure 1 , 2 , 3, 4, 7, 8: This new large-angle rotary horizontal band sawing machine includes a base frame 1, which is characterized in that: the base frame 1 is rotatably connected with a rotating disc 2, and the rotating disc 2 is fixed with a square pole 3 A set of first reinforcing ribs 3-1 is fixed between the bottom of the square pole 3 and the top of the rotating disc 2, the square pole 3 is provided with a sawing frame body 4 sliding on the square pole 3 along the "Z" direction, A driving pulley 5 and a driven pulley 6 are installed on the sawing frame body 4, a saw blade 7 is installed between the driving pulley 5 and the driven pulley 6, and the driving pulley 5 passes through the sawing frame body 4 on the first Driven by a servo motor 8, the rotating disk 2 is fixed with a first hydraulic cylinder 9 that drives the sawing frame body 4 to move up and down, and the base frame 1 is fixed with a drive mechanism 10 for driving the rotating di...

Embodiment 2

[0036] Refer to attached figure 1 , 2 , 3, 4, 5, 7, 8: This new large-angle rotating horizontal band sawing machine includes a base frame 1, a rotating disc 2 is connected to the base frame 1, and a square pole 3 is fixed on the rotating disc 2. A set of first reinforcing ribs 3-1 is fixed between the bottom of the pole 3 and the top of the rotating disk 2, and the square pole 3 is provided with a sawing frame body 4 that slides on the square pole 3 along the "Z" direction. A driving pulley 5 and a driven pulley 6 are installed on the frame body 4, a saw blade 7 is installed between the driving pulley 5 and the driven pulley 6, and the driving pulley 5 is cut by the first servo motor on the frame body 4. 8 drive, the first hydraulic cylinder 9 that drives the sawing frame body 4 to move up and down is fixed on the rotating disk 2, and the driving mechanism 10 for driving the rotating disk 2 to rotate is fixed on the base frame 1.

[0037] Driving mechanism 10 comprises the ...

Embodiment 3

[0046] Refer to attached figure 1 , 2 , 3, 4, 6, 7, 8: This new type of large-angle rotary horizontal band sawing machine includes a base frame 1, on which a rotating disc 2 is rotatably connected, and a square pole 3 is fixed on the rotating disc 2. A set of first reinforcing ribs 3-1 is fixed between the bottom of the pole 3 and the top of the rotating disk 2, and the square pole 3 is provided with a sawing frame body 4 that slides on the square pole 3 along the "Z" direction. A driving pulley 5 and a driven pulley 6 are installed on the frame body 4, a saw blade 7 is installed between the driving pulley 5 and the driven pulley 6, and the driving pulley 5 is cut by the first servo motor on the frame body 4. 8 drive, the first hydraulic cylinder 9 that drives the sawing frame body 4 to move up and down is fixed on the rotating disk 2, and the driving mechanism 10 for driving the rotating disk 2 to rotate is fixed on the base frame 1.

[0047] The driving mechanism 10 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com