A control system and method for the current of tokemak ohmic heating coil

A technology of ohmic heating and coil current, applied in electrical components, plasma, etc., can solve the problems of uncontrollable current zero-crossing time, circulation mode operation and control time delay, etc., to achieve good portability, good real-time performance, and stability. The effect of efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A current control system and method for a tokamak ohmic heating coil according to the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

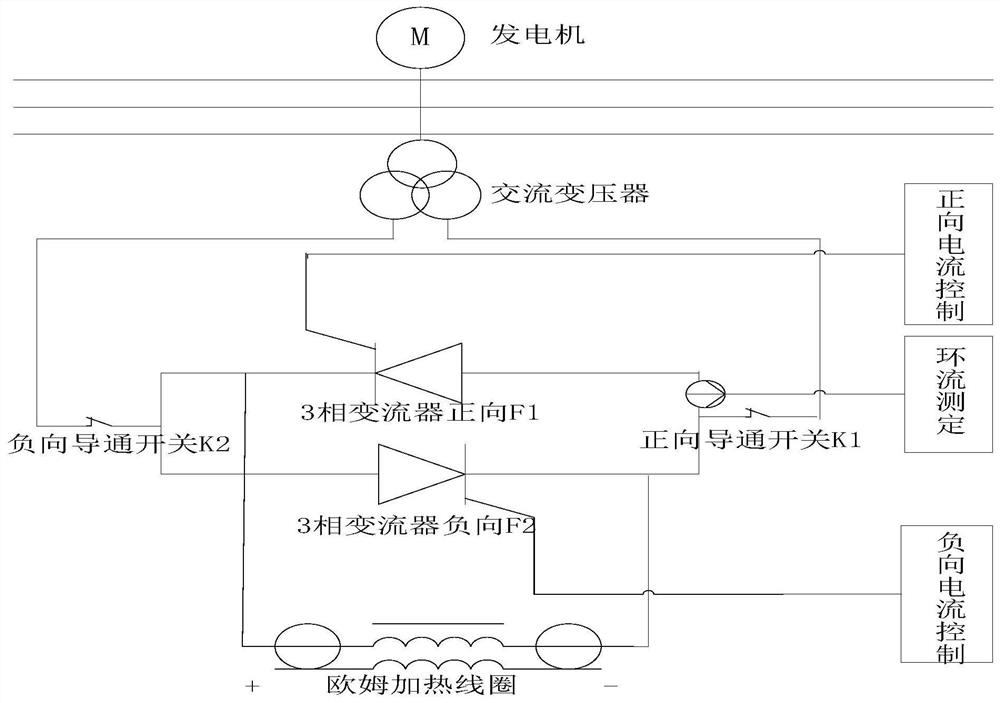

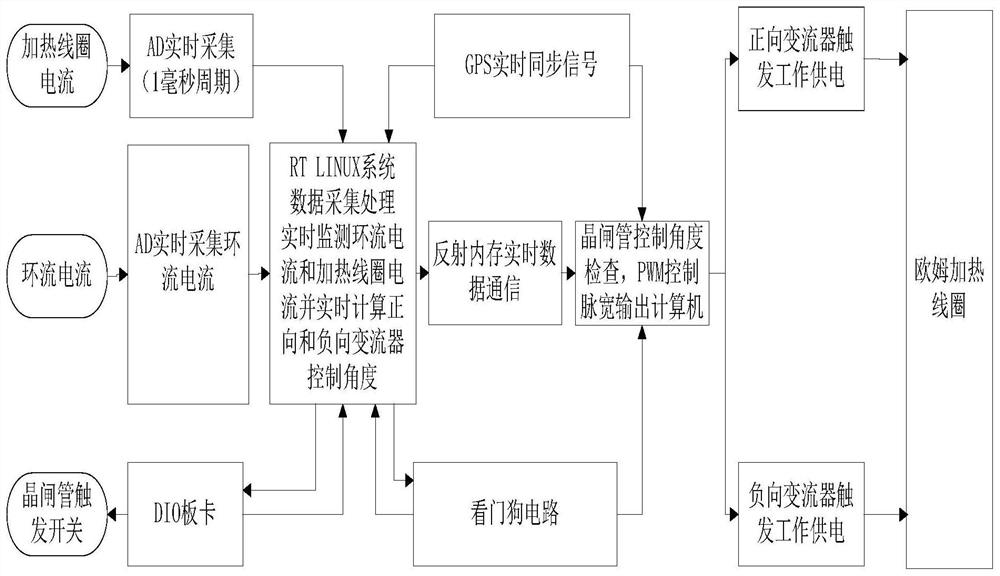

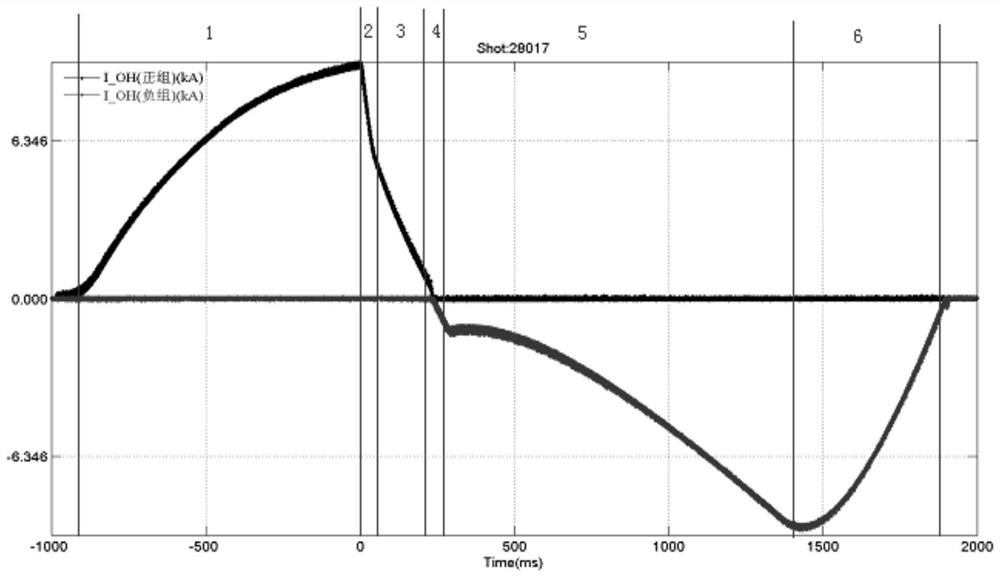

[0042] Such as Figure 1 to Figure 4 As shown, a real-time control system of a Tokmak ohmic heating coil current in the present invention includes an ohmic heating coil power supply circuit, a real-time controller, a reflective memory card, a conduction angle computer, a GPS clock and a watchdog;

[0043] The power supply circuit of the ohmic heating coil is powered by the ohmic heating coil, the real-time controller is electrically connected to the power supply circuit of the ohmic heating coil, and the real-time controller, reflective memory card, conduction angle computer, GPS clock and watchdog are connected in series;

[0044] The real-time controller collects the current in the ohmic coil in real time through the collected ohmic heating coil current and the target cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com