Mechanical watertight connector

A watertight connector, a mechanical technology, applied in the direction of connection, parts of connecting devices, devices for reducing the stress at the connection of wires, etc., can solve the problems of non-removable sealing structure, inseparable from watertight connectors, etc., and achieve production efficiency High, good seawater corrosion resistance, ensure the effect of electrical connection and maintenance and repair of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

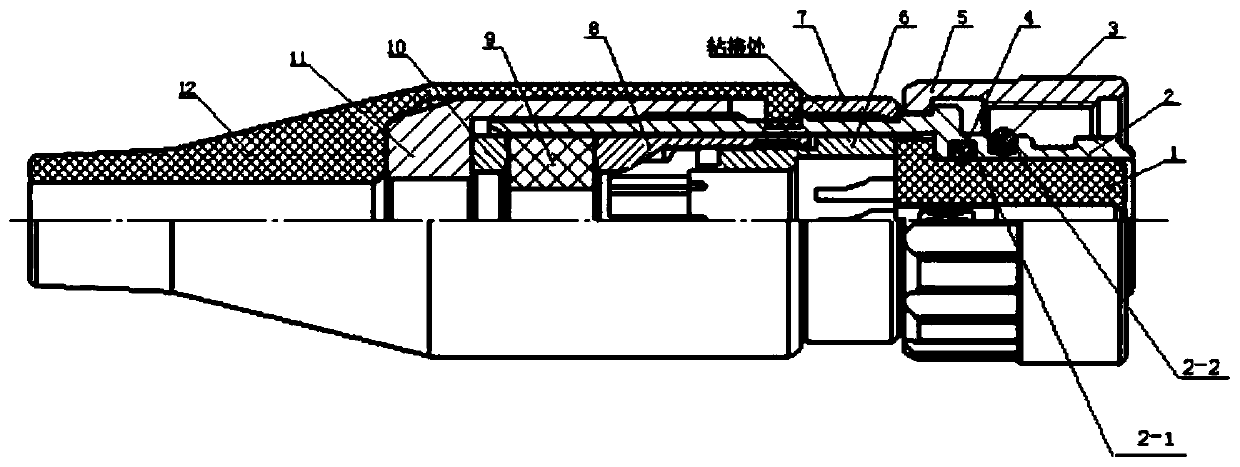

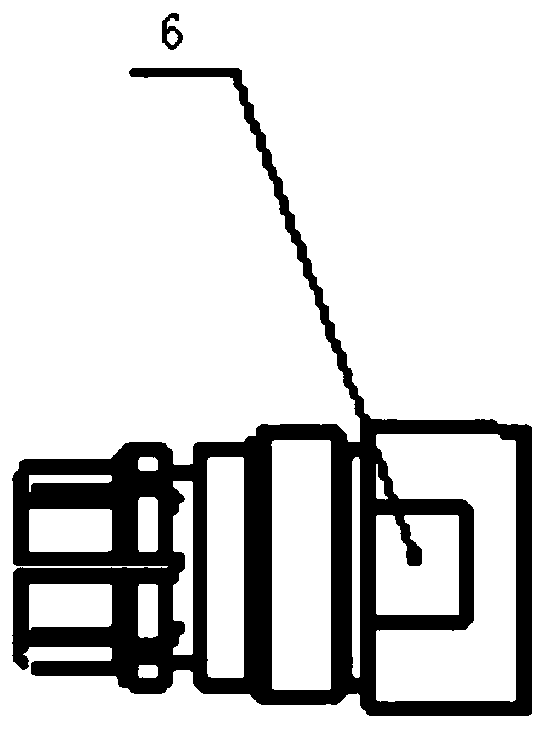

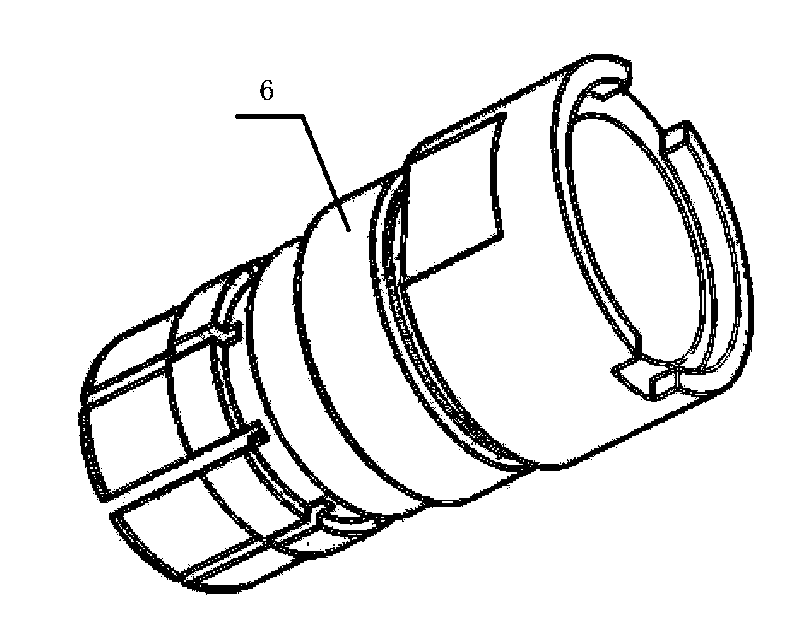

[0021] refer to figure 1 and Figure 4 , a mechanical watertight connector, the watertight connector includes a jack insulator assembly 1, a plug housing 2, a connecting nut 5, a clamping barrel 6, a limit nut 7, a clamping barrel nut 8, a waterproof pad 9. Compression ring 10, tail nut 11 and rubber sleeve 12; the jack insulator assembly 1 is installed inside the plug housing 2, and a clamp barrel 6 is installed at the tail end of the jack insulator assembly 1, and the jack insulator assembly 1. It includes the hole insulator and the jack axially installed in the hole insulator. The tail end of the jack is fixed with the cable. The outer circumference of the tail end of the clamping barrel 6 is threaded butt joint with a clamping barrel nut 8. Tighten the clamping barrel The nut 8 compresses the clamping barrel 6 to clamp the cable axially passing through the clamping barrel 6. The tail end of the clamping barrel nut 8 is provided with a waterproof pad 9, and the tail end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com