Auxiliary device for installation of grounding wire

An auxiliary device and grounding wire technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of unreliable installation, difficult installation of grounding wire, low installation efficiency, etc., to achieve convenient connection, reliable installation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

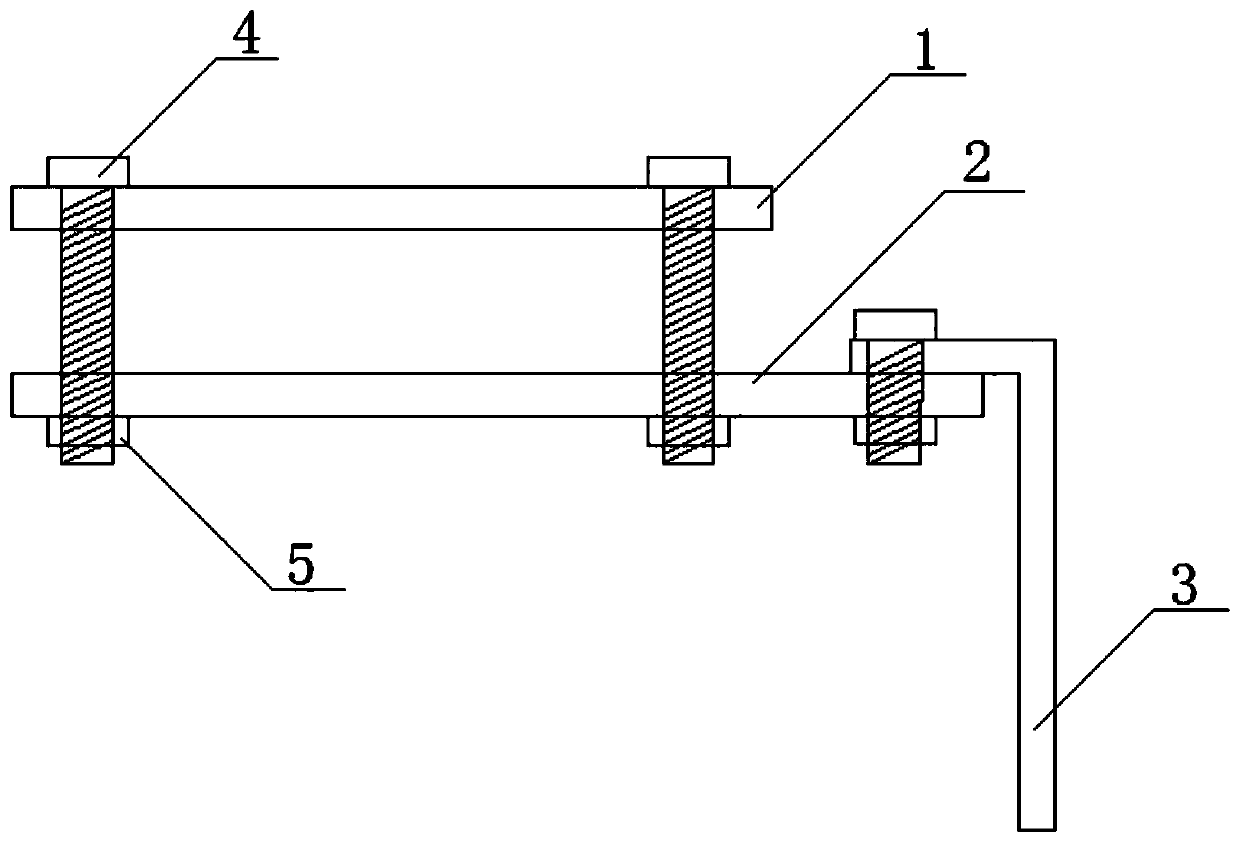

[0026] Such as figure 1 Shown is a schematic structural diagram of the grounding wire installation auxiliary device of this embodiment.

[0027] The grounding wire installation auxiliary device of this embodiment includes a first splint 1, a second splint 2, and a conductor 3, wherein the two ends of the first splint 1 are provided with screw holes, and the second splint 2 corresponds to the screw holes provided by the first splint 1. A screw hole is provided at the position of the hole, the conductor 3 is arranged at one end of the second splint 2 , and the angle between the conductor 3 and the second splint 2 is 90 degrees. Wherein, the first splint 1 and the second splint 2 are connected and fixed through the screw holes provided by the bolts 4 and the nuts 5 .

[0028] The conductor 3 in this embodiment is a copper row.

[0029] The first splint 1 and the second splint 2 in this embodiment are busbar splints made of copper.

[0030] In the specific implementation proces...

Embodiment 2

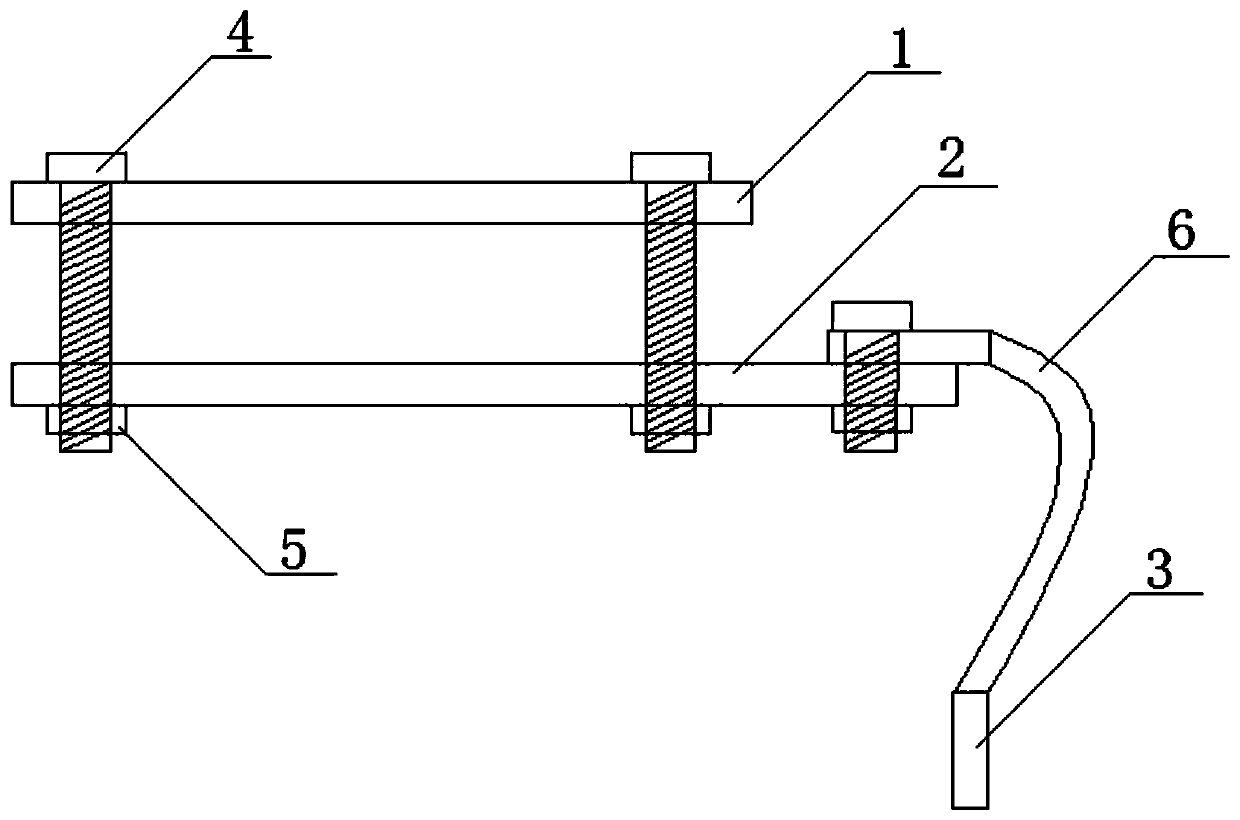

[0033] Such as figure 2 Shown is a schematic structural diagram of the grounding wire installation auxiliary device of this embodiment.

[0034] The grounding wire installation auxiliary device in this embodiment includes a first splint 1, a second splint 2, and a conductor 3, wherein the two ends of the first splint 1 are provided with screw holes, and the second splint 2 corresponds to the opening of the first splint 1. Screw holes are provided at the positions of the screw holes. Wherein the first splint 1 and the second splint 2 are connected and fixed through the screw holes provided by the bolts 4 and the nuts 5 .

[0035] In this embodiment, a screw hole is provided at the position where one end of the second splint 2 is connected to the conductor 3 , and the second splint 2 is connected and fixed to the conductor 3 through the screw hole provided by the bolt 4 and the nut 5 .

[0036] The conductor 3 in this embodiment is a copper row.

[0037] The first splint 1 a...

Embodiment 3

[0041] Such as figure 2 Shown is a schematic structural diagram of the grounding wire installation auxiliary device of this embodiment.

[0042] The grounding wire installation auxiliary device in this embodiment includes a first splint 1, a second splint 2, and a conductor 3, wherein the two ends of the first splint 1 are provided with screw holes, and the second splint 2 corresponds to the opening of the first splint 1. Screw holes are provided at the positions of the screw holes. Wherein the first splint 1 and the second splint 2 are connected and fixed through the screw holes provided by the bolts 4 and the nuts 5 .

[0043] The grounding wire installation auxiliary device in this embodiment also includes an annealed copper wire 6 for connecting with the conductor 3, and one end of the second splint 2 in this embodiment is provided with a screw hole, wherein one end of the annealed copper wire 6 is passed through a bolt 4 and the nut 5 are connected and fixed to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com