Handheld controller used for underwater equipment

A technology for underwater equipment and controllers, applied in the field of handheld controllers, can solve problems such as unsuitable installation, low reliability, and high technical difficulty, and achieve the effects of reducing control costs, simple and reliable sealing, and expanding the application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

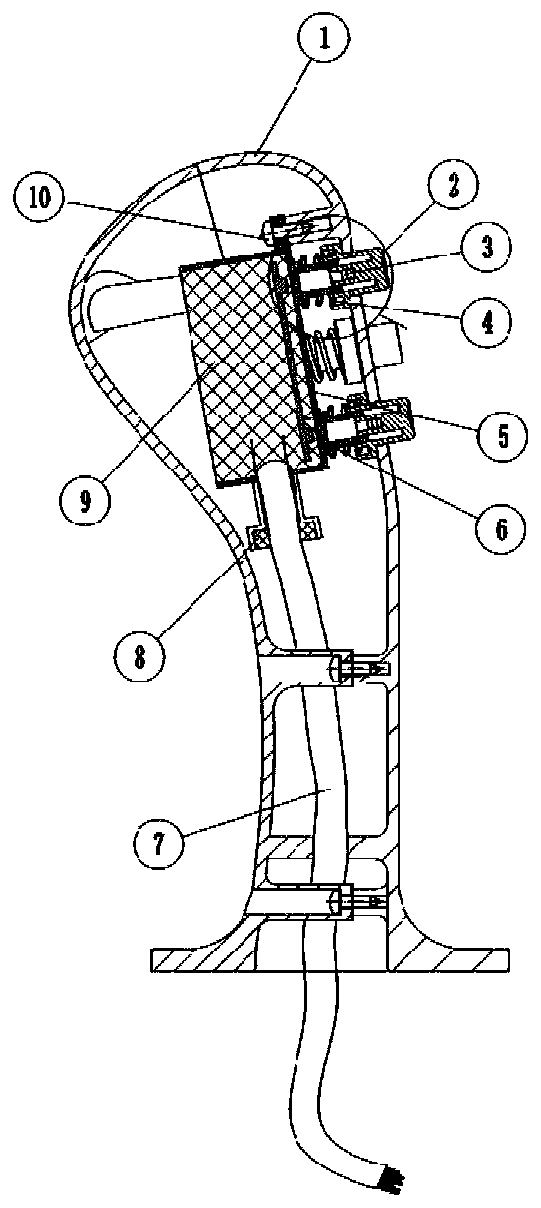

[0070] Such as Figure 1-5 , shown in 8 and 9, is a hand-held controller under a push mode. The present invention (a hand-held controller based on underwater equipment control) is installed on the equipment, and the operation control is performed through the key 2 . The control panel 6 is sealed with a waterproof sealant 9, and the outlet of the waterproof line 7 is sealed with a primary sealant 8, so that the control panel is completely in a sealed environment.

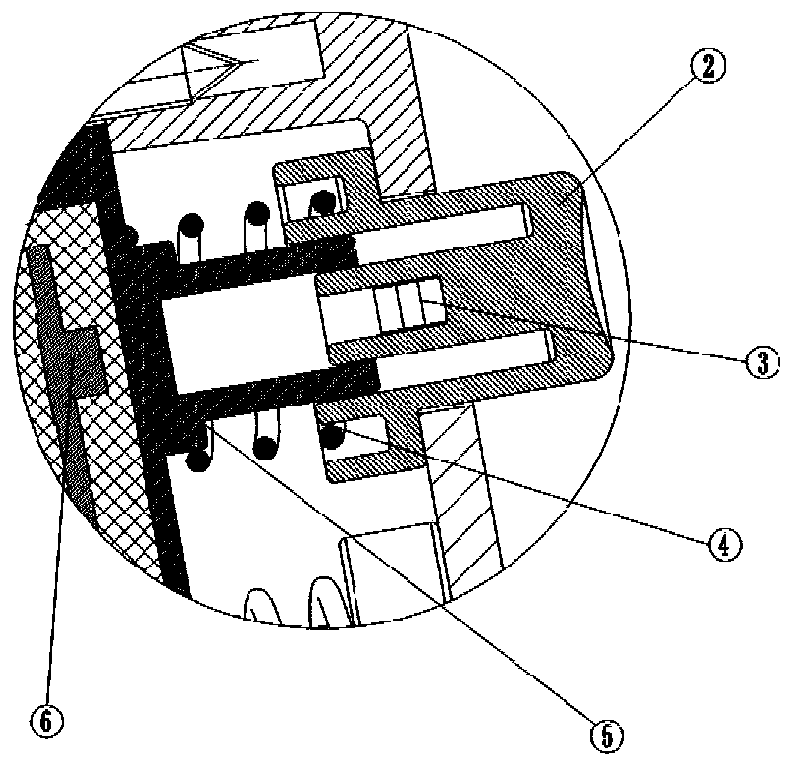

[0071] The button part is composed of a button 2, a separate sensor 3, a return spring 4, and a control package box 5 (a spring guide column and a button guide rail are provided on the push installation shell). The cost of the controller is reduced, and the button part is easy to install, disassemble and maintain, and has good mechanical performance.

[0072] see Figure 9 , the induction circuit of the control board is as follows: the VCC pin of the Hall element (Q20, Q21) is directly connected to the positive po...

Embodiment 2

[0079] Such as Image 6 , 7 As shown, the present invention can also be used for sliding control under the sliding mode, and the distance between the separate inductor (3) and the inductors Q20 and Q21 on the main control board 6 is designed as the sensing distance. The main control board 6 is provided with There are multiple groups of Q20 and Q21 (the sensor group is designed according to the actual signal group), so that one of the sensor groups (Q20 and Q21) can be triggered at any position as long as it is within the sensing range when sliding, so as to issue an operation command and realize Swipe the slider to control the signal of the device.

Embodiment 3

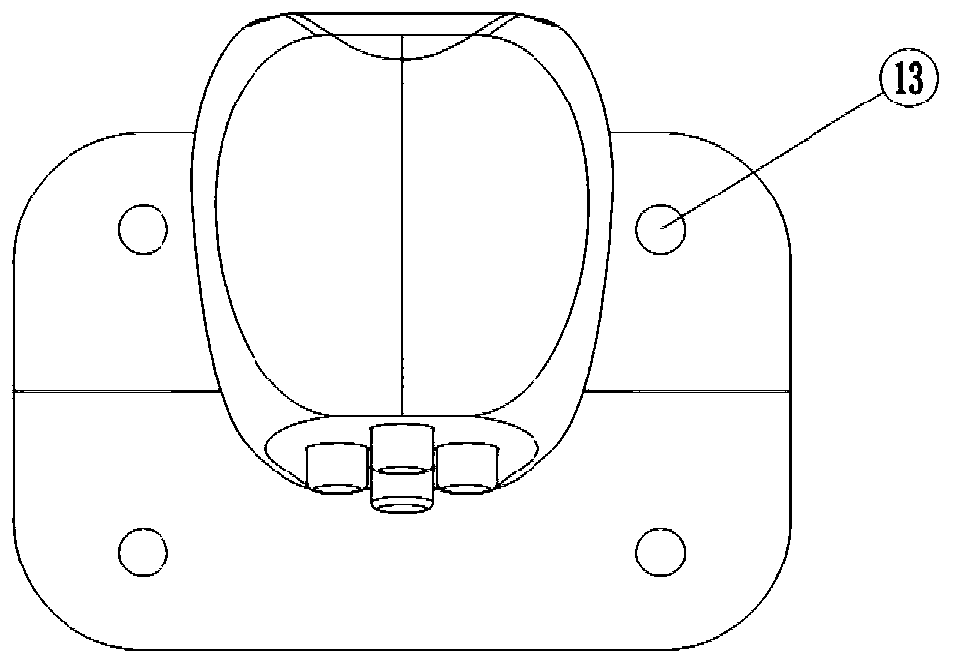

[0081] The present invention is applied to the control of equipment (with thrusters on both sides of the equipment): as Figure 4 As shown, define the four keys on the remote control: the front, back, left, and right keys correspond to the forward, backward, left, and right turns of the device respectively.

[0082] When the "front button" is pressed, the main control board 6 sends a "forward" command signal after the main control board 6 receives the "advance" command. The right propeller and the left propeller rotate forward at the same time as the executive equipment, and the underwater equipment advances.

[0083] When the "back button" is pressed, the main control board 6 sends a "backward" command signal after the main control board 6 receives the "backward" command. The right thruster and the left thruster stop forward rotation and reverse at the same time, and the underwater equipment moves backward.

[0084] When the "left button" is pressed, the main control board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com