Electric heating pipe head multifunctional protecting connector and electric heating pipe head sealing method

An electric heating tube, multi-functional technology, applied in the sealing of the engine, the shape of the heating element, the engine components, etc., can solve the problems of overcurrent damage of the electric heating tube, material leakage, rupture of the electric heating tube shell, etc., and achieve reliable sealing, Guarantees insulation performance and prevents leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

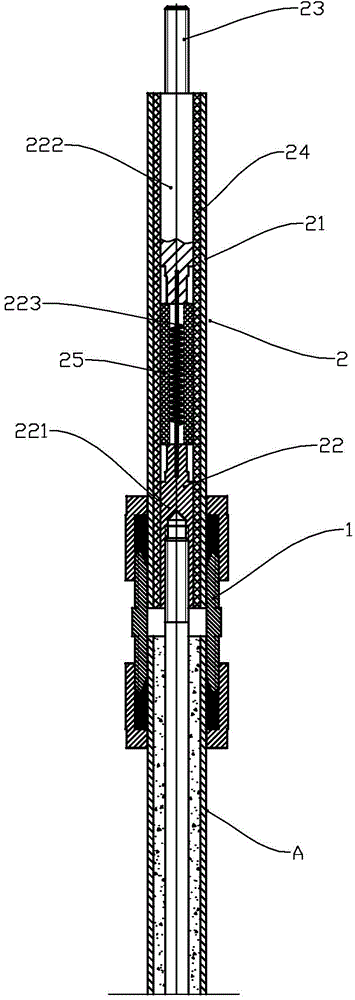

[0013] As shown in the figure, the embodiment of the electric heating tube multifunctional protective connector of the present invention includes a pipe joint 1 and a sealing tube assembly 2; the sealing tube assembly includes a section of a metal outer tube 21 and a central conductor 22 located at the center of the metal outer tube, One end of the central conductor has a structure that can be matched and connected with the lead-out conductor of the electric heating tube, and the other end of the central conductor has a lead-out rod 23 that can be connected to an external power source; the central conductor 22 and the metal outer tube 21 are sealed by polytetrafluoroethylene material The sleeve 24 is sealed and filled; the pipe joint 1 (a known bite-type pipe joint can be used) can seal the metal outer pipe 21 and the tubular shell of the electric heating pipe 3. The central conductor 22 is composed of a front conductive bar 221 located in the front section, a rear conductive ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com